A new type of flapping wing propulsion device and its working process

A propulsion device, a new type of technology, applied in the direction of propulsion-based emission reduction, transportation and packaging, helicopters, etc., can solve the problem of no optimization space, etc., and achieve the effect of compact structure, improved propulsion efficiency, and reduced energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

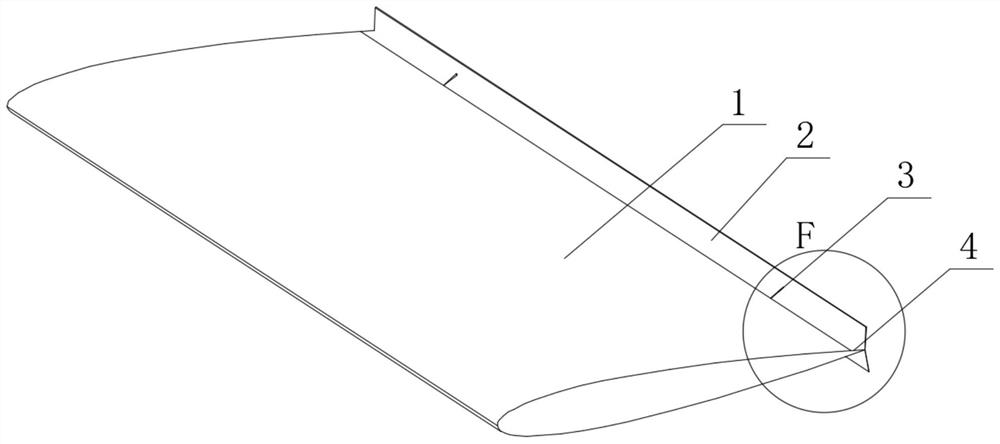

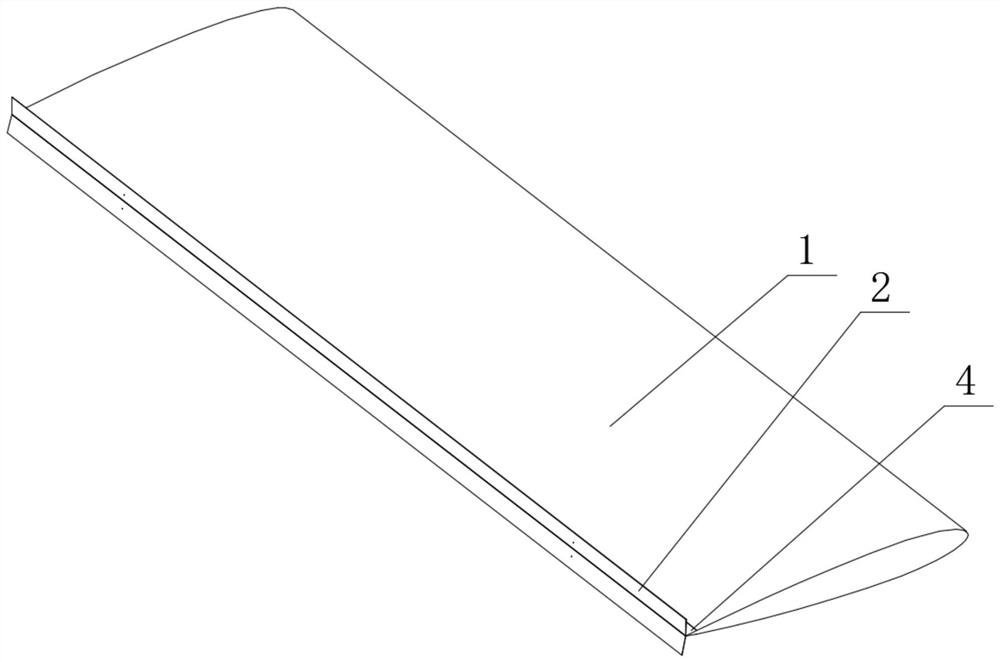

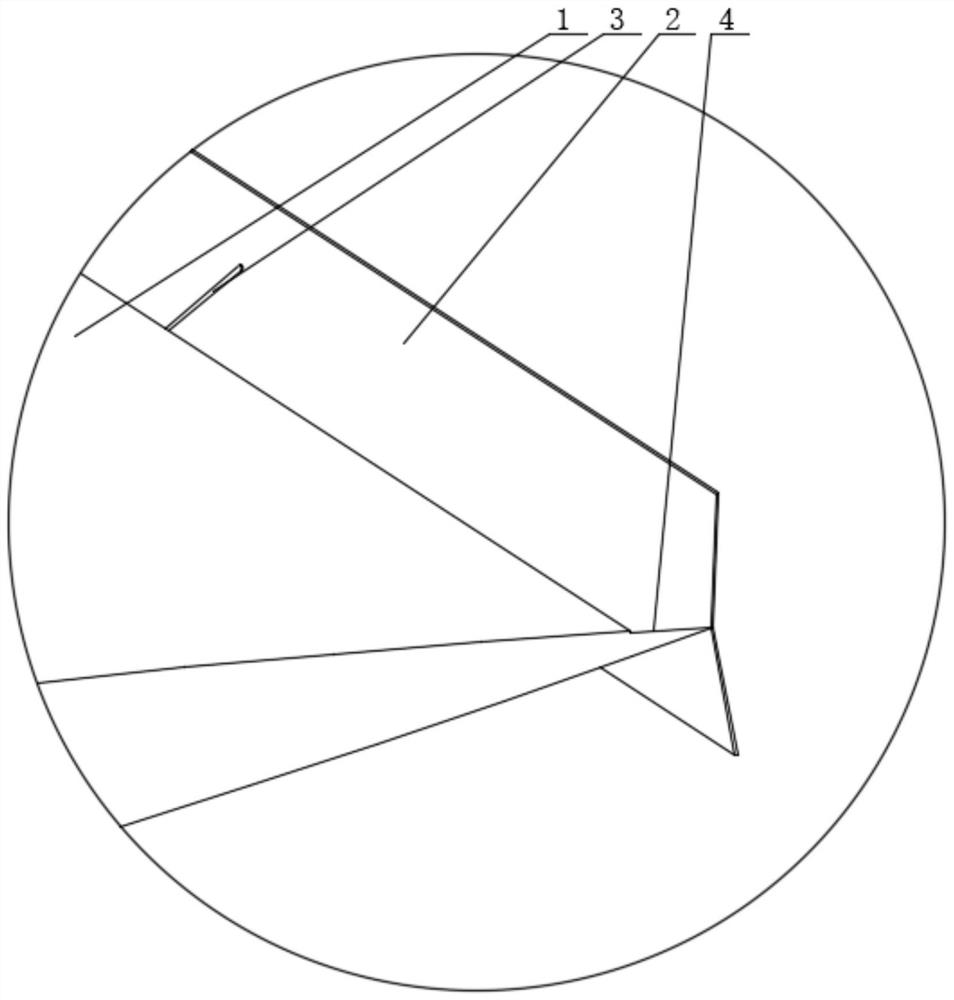

[0035] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0036] like Figure 1-Figure 8 As shown, the novel flapping wing propulsion device of this embodiment includes a flapping wing body 1, a pair of tail sealing plates 2 are hinged at the trailing edge of the flapping wing body 1, and a A plurality of retracting rods 3 are installed between the tail sealing plate 2 and the stepped surface 4, and the movement of the retracting rods 3 controls the opening and closing of the tail sealing plate 2.

[0037] The flapping wing body 1 adopts the NACA0012 profile airfoil with an aspect ratio of 3.0.

[0038] The length of the tail cover plate 2 is equal to the extension of the flap body 1 .

[0039] The height of the tail cover 2 is equal to the maximum thickness of the flap body 1 .

[0040] When the tail sealing plate 2 is opened, the tail sealing plate 2 is perpendicular to the step surface 4;

[0041] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com