Anti-skid tray based on air pressure adsorption

A non-slip, tray technology, applied in trays and other directions, can solve the problems of waste, tray utensils sliding, food spills, etc., to achieve a wide range of applications, good anti-slip effect, and prevent utensils from sliding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

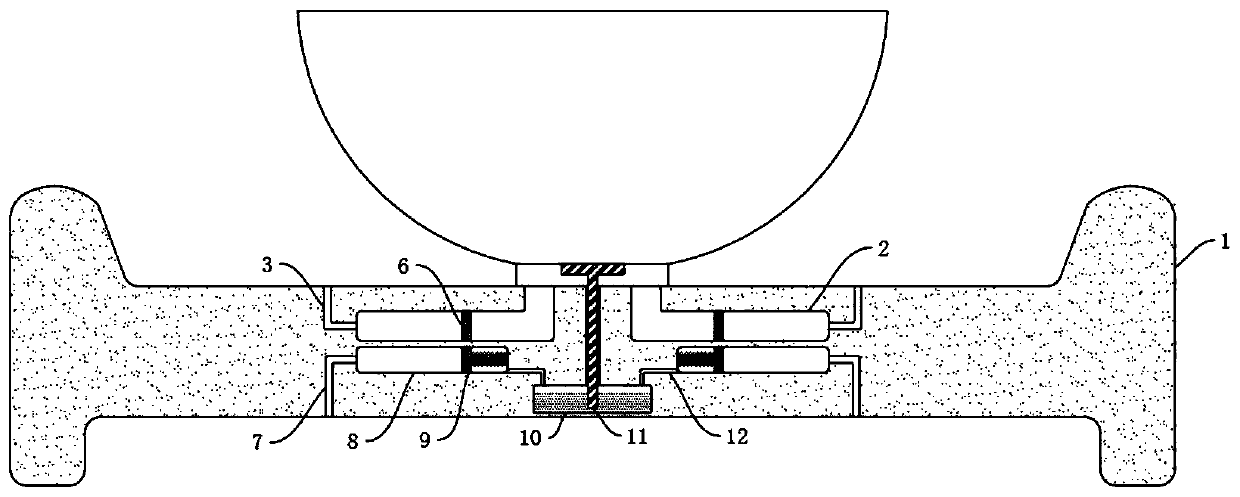

Method used

Image

Examples

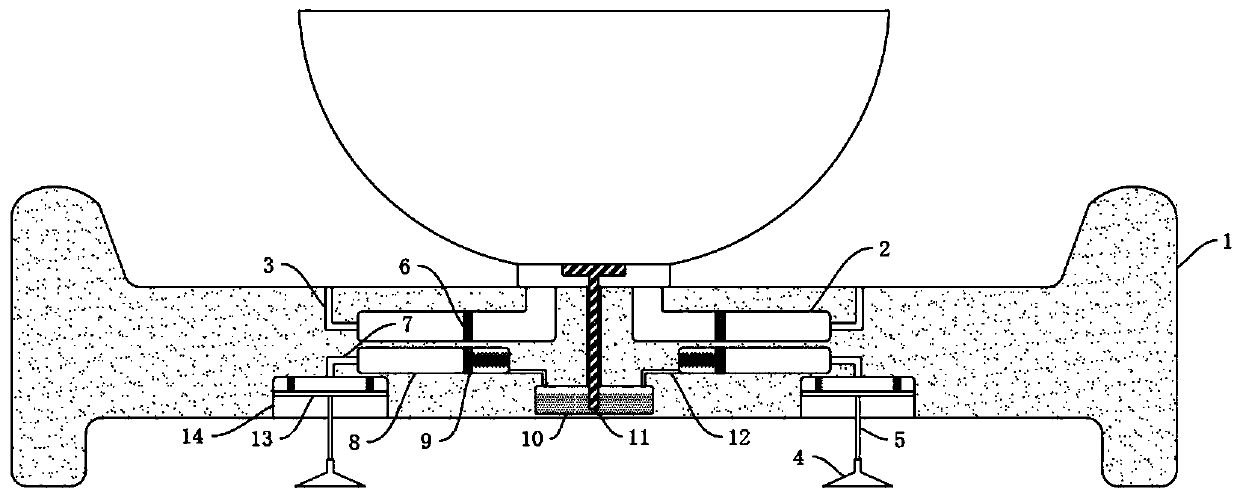

Embodiment 2

[0027] refer to figure 2 , a non-slip tray based on air pressure adsorption. The lower wall of the pallet 1 is provided with two fixing grooves 14, and the ends of the two placement cavities 8 away from the active magnetic block 9 communicate with the two fixing grooves 14 through the air outlet pipe 7 respectively. The upper wall of groove 14 is elastically connected with sliding plate 13 by a plurality of extension springs, and the cross-sectional area of fixed groove 14 is four times of the cross-sectional area of placement chamber 8, so that the sliding plate 13 only needs to move a small distance to be able to A large negative pressure is generated between the sliding plate 13 and the active magnetic block 9, the sliding plate 13 is connected to the inner wall of the fixed groove 14 in a sealed sliding manner, the lower wall of the sliding plate 13 is fixedly connected with the vertical rod 5, and the lower end of the vertical rod 5 is fixedly connected with the sucti...

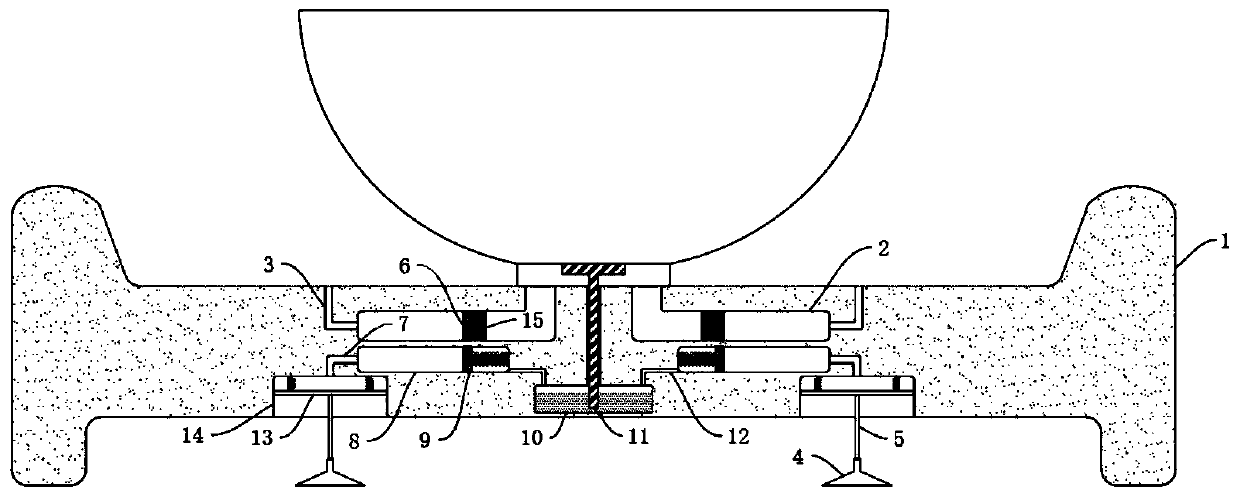

Embodiment 3

[0030] refer to image 3 , a non-slip tray based on air pressure adsorption. The supporting plate 1 is made of heat insulating material to ensure that the heat on the heat conducting plate 11 will not be conducted away by the supporting plate 1, thereby ensuring that the heat conducting plate 11 can quickly evaporate the low boiling point evaporating liquid A cooling fin 15 is fixedly connected to the side wall of the end of the driven magnetic block 6 away from the exhaust pipe 3 .

[0031] In this embodiment, the cooling fins 15 can reduce the temperature of the air between the driven magnetic block 6 and the bottom of the container. According to the Clapeyron equation PV=nRT, the lower the temperature, the smaller the pressure, so that the bottom of the container and the bottom of the container The smaller the air pressure between the driven magnetic blocks 6 is, the greater the pressure difference will be, so that the vessel will be more firmly adsorbed and the anti-slip e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com