Shell and tube heat exchanger

A technology of shell-and-tube heat exchangers and heat exchange tubes, which is applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., and can solve the problem of reducing heat exchange tube cutting, flat tube work, and U-shaped tubes Difficult assembly, scratches on heat exchange tubes, etc., to achieve good flow field characteristics, high cost performance, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

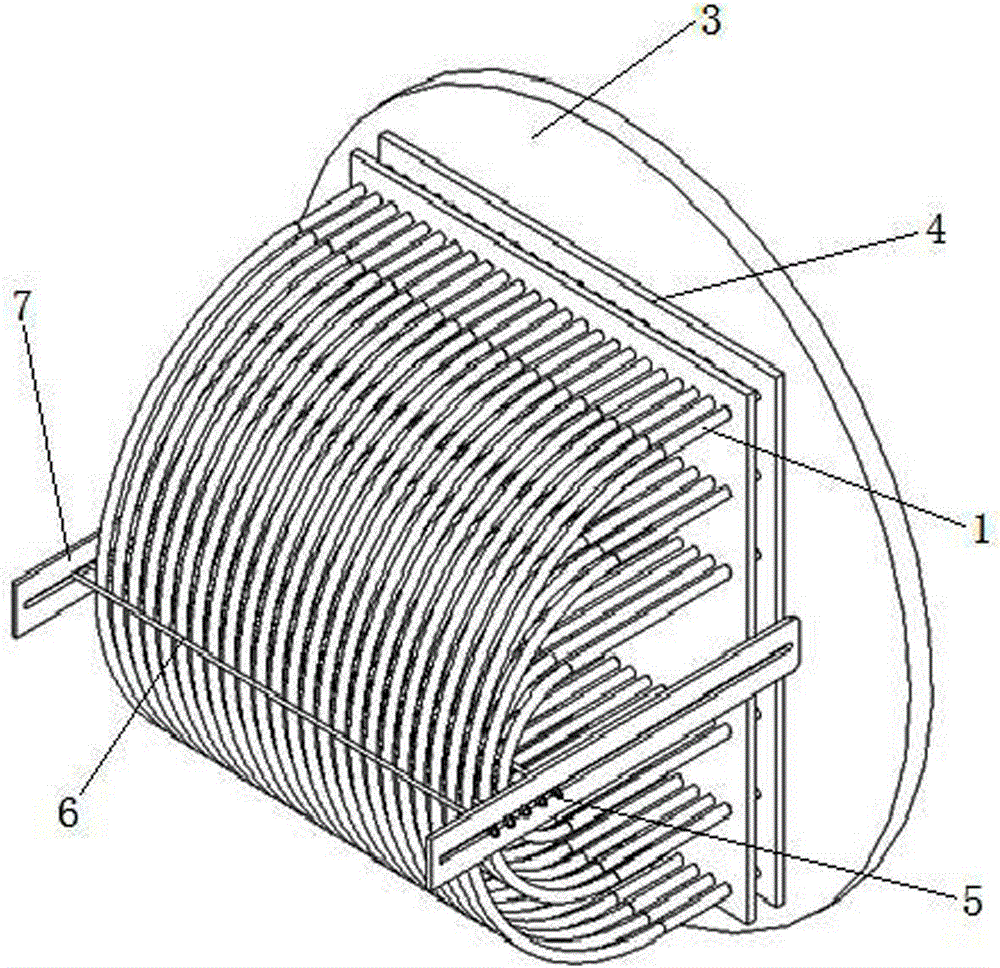

[0016] The invention is a shell-and-tube heat exchanger, which is provided with a U-shaped heat exchange tube system arranged in n layers from the inside to the outside. On the end tube plate 3. In this specific embodiment, the U-shaped heat exchange tube system has 3 layers, and the U-shaped heat exchange tube 1 of each layer increases in length and outline from the inside to the outside, and its number and shape can be designed and changed according to heat exchange needs.

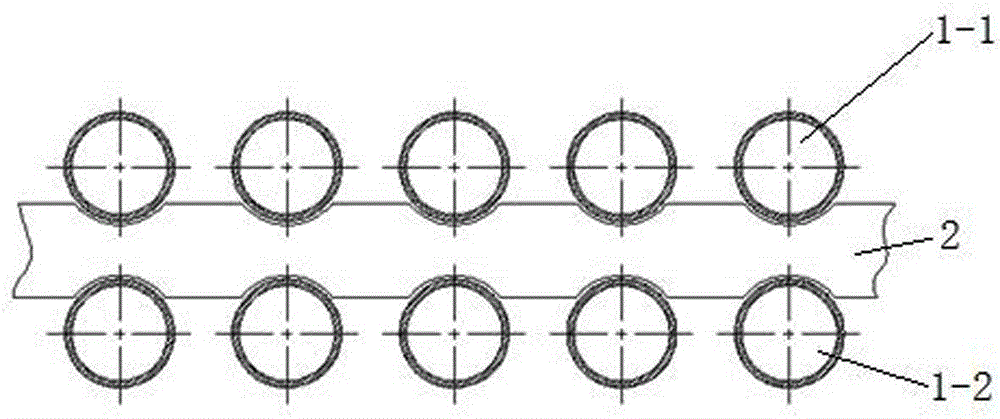

[0017] figure 2 The structural form of the sliding anti-collision limiting device of the U-shaped heat exchange tube system in the shell-and-tube heat exchanger of the present invention is described in detail in , and its use and assembly structure with the U-shaped heat exchange tube 1 is described in detail. Such as figure 2 As shown, an anti-collision limiting device is provided between each layer of U-shaped heat exchange tubes 1 , and the anti-collision limiting device includes a positioning pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com