Preparation method of AR diffraction optical waveguide imprinting mold, soft mold and application

A diffracted light and soft mold technology, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of high-efficiency and low-cost preparation of large-area tilted grating imprinting molds, high cost and complicated process steps, etc., to achieve manufacturing Low cost, low production cost, and the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

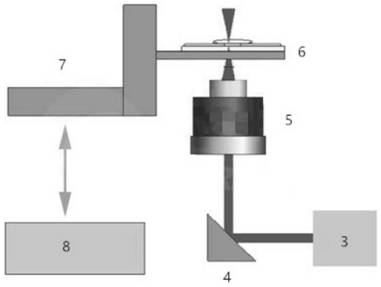

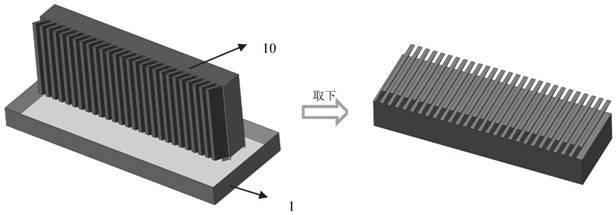

[0064] figure 1 It is a schematic diagram of an electroforming mask to be manufactured by the present invention and the specific parameters of the diffractive optical waveguide (surface relief oblique grating) that it can manufacture, wherein inclination angle, groove depth (relative depth), line width, fill factor (grating width / period) such as figure 1 mentioned. The parameters of the metal mold to be manufactured in this implementation example: the inclination angle is 35°; the groove depth is 330nm; the line width is 220nm, the period is 405nm, and the filling factor (coefficient) is 55%. A photoresist 2 is provided on the surface of the nickel plate 1 .

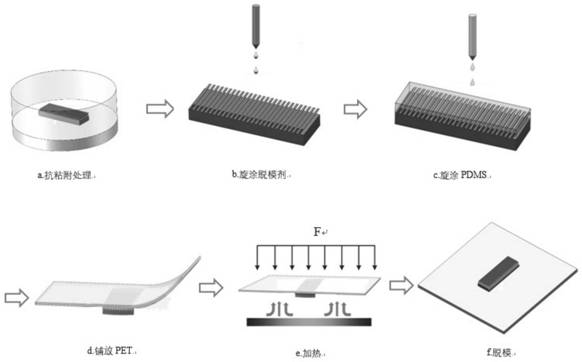

[0065] Taking the tilted grating nanoimprint mold described in the implementation example as an example, combined with Figure 1-Figure 6 , specifically explain the specific process of manufacturing tilted grating nanoimprint mold based on the proposed method and equipment.

[0066] Step 1: Print the electroforming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com