Electrolytic corrosion device for releasing metal mold cores of micro-sized shell-type parts

An electrolytic corrosion and metal mold technology, applied in electrolytic components, electrolytic processes, metal processing equipment, etc., can solve problems such as increased production costs, harmful gases, and slow removal rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

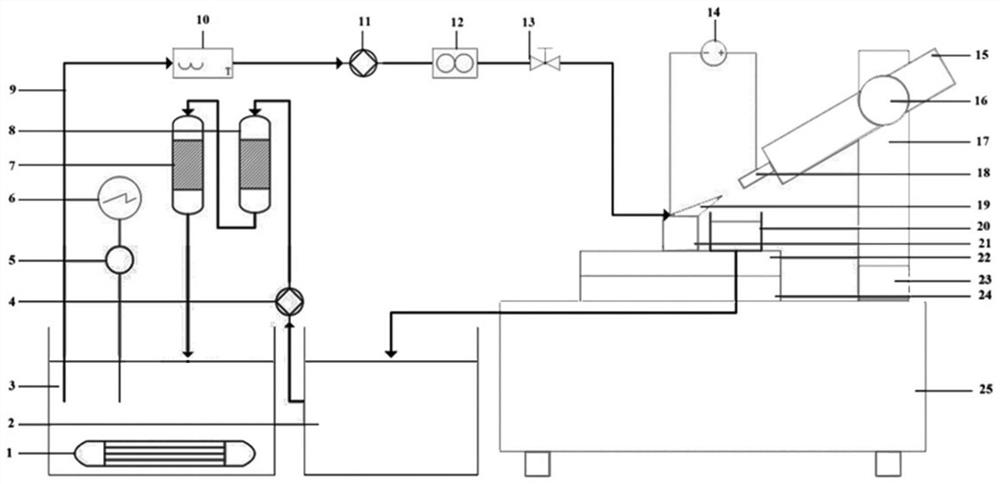

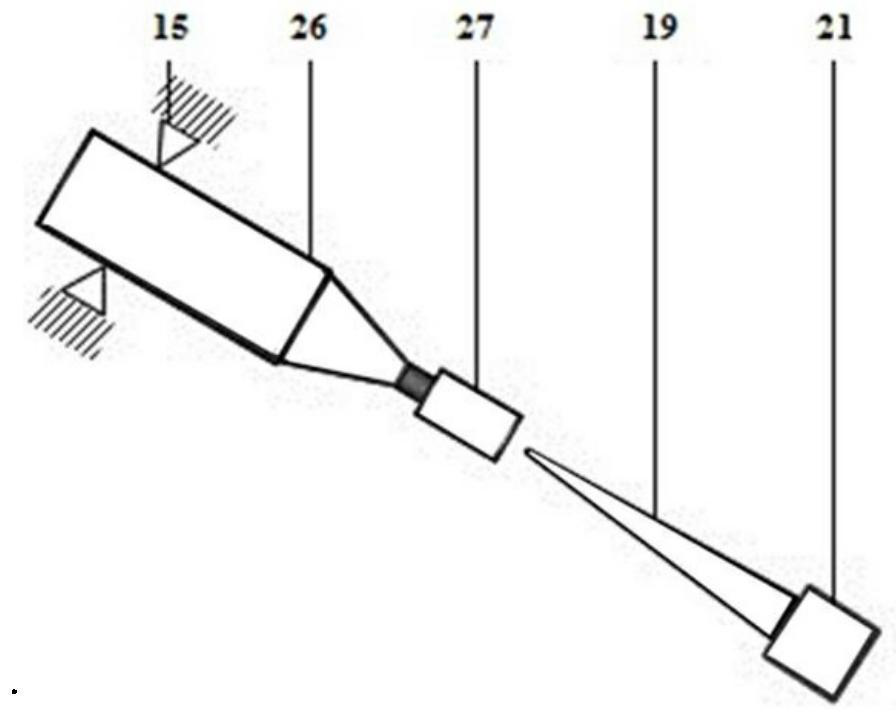

[0019] like Figure 1~2 As shown, an electrolytic corrosion device for demolding metal mold cores of micro-sized shell-type parts, including a cathode system, an anode clamping system, an electrolyte circulation filtration system, and an ion concentration online detection system;

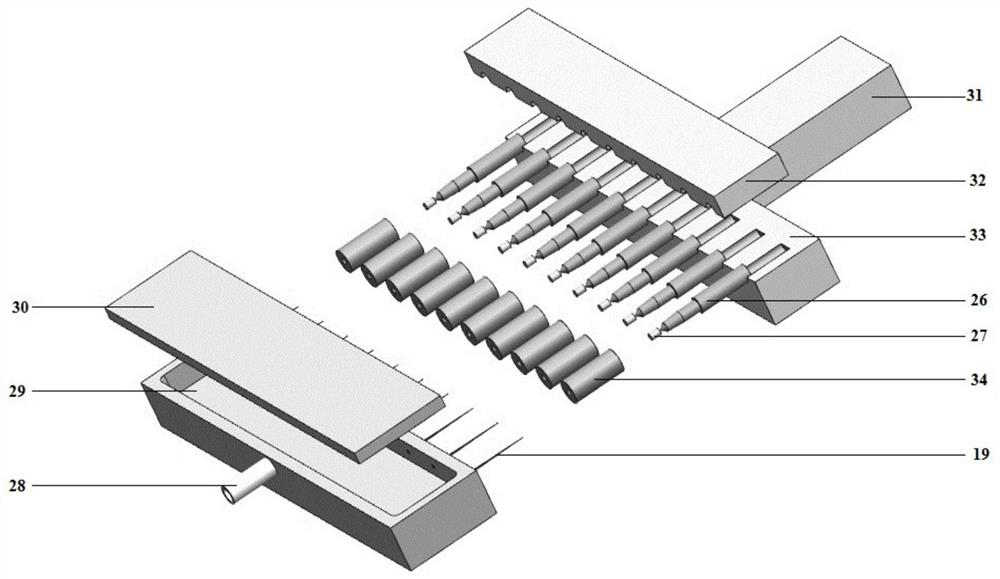

[0020] The cathode system includes a nozzle 19, a cathode 21 and an X-axis moving platform 22 or a Y-axis moving platform 24 that drives the cathode in the X-axis or Y-axis direction. The nozzle and the cathode are connected, and the alignment of the cathode and the anode workpiece is adjusted by moving the platform. The cathode includes an electrolyte inlet 28, an electrolyte box 29 and a cathode cover 30, the electrolyte inlet is communicated with the electrolyte box, and a cathode cover is provided on it;

[0021] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com