A Method for Adding Air Between Stages of a Large-Flow Compact Centrifugal Compressor

A centrifugal compressor, compact technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of increased radial size of the unit, increased installation height of the aeration volute, complicated manufacturing, etc., to simplify the design and processing, good flow field characteristics, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

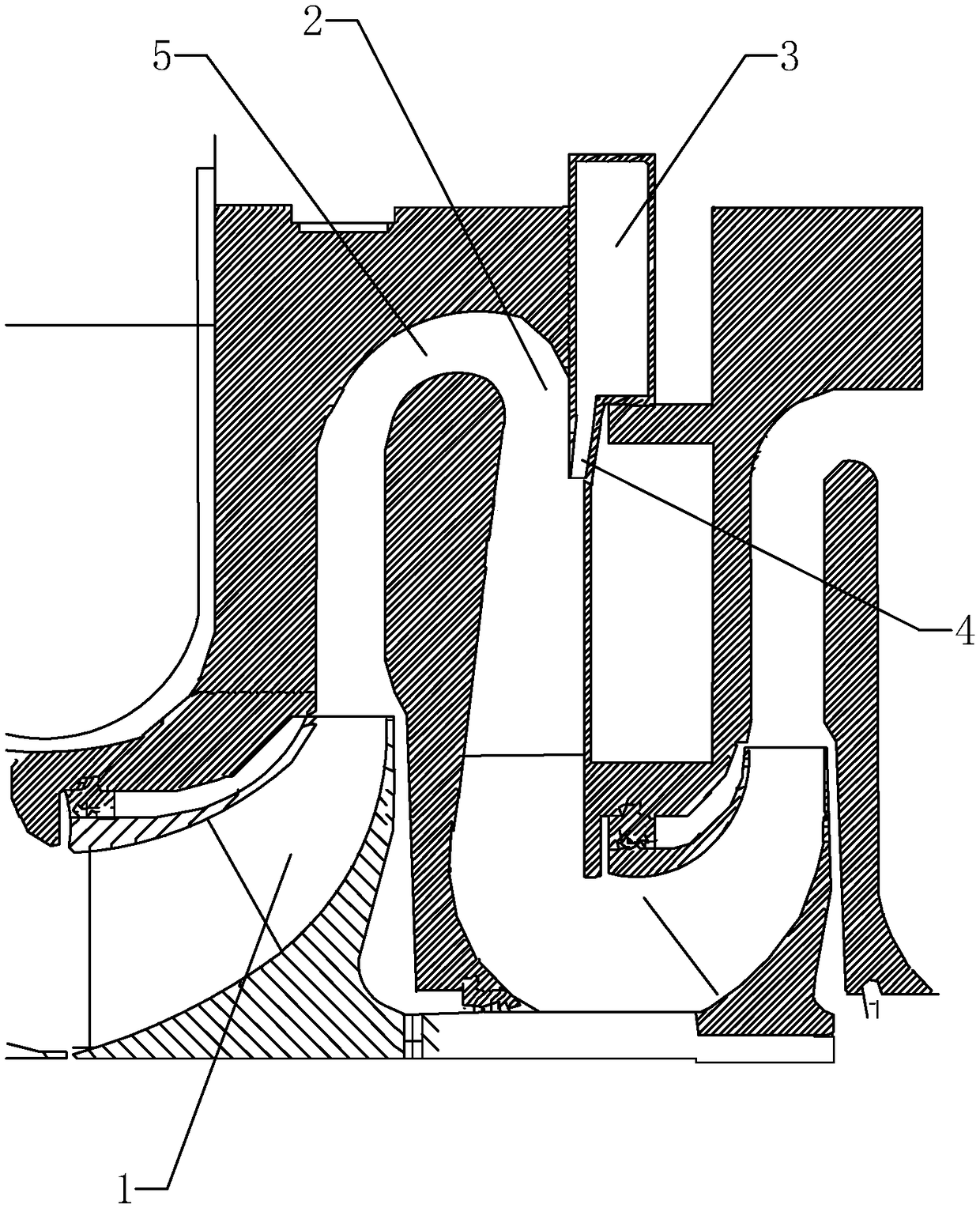

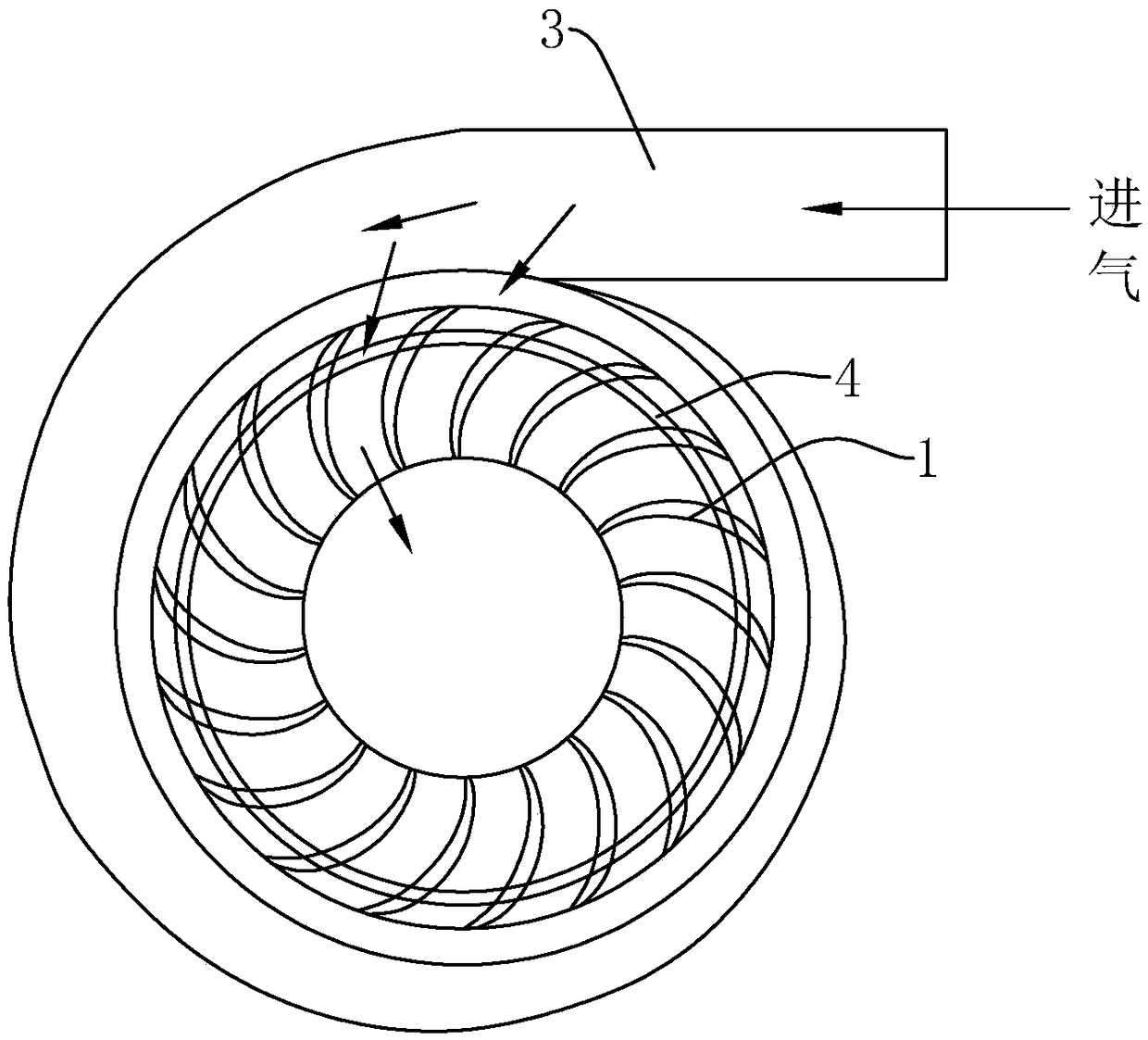

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] in

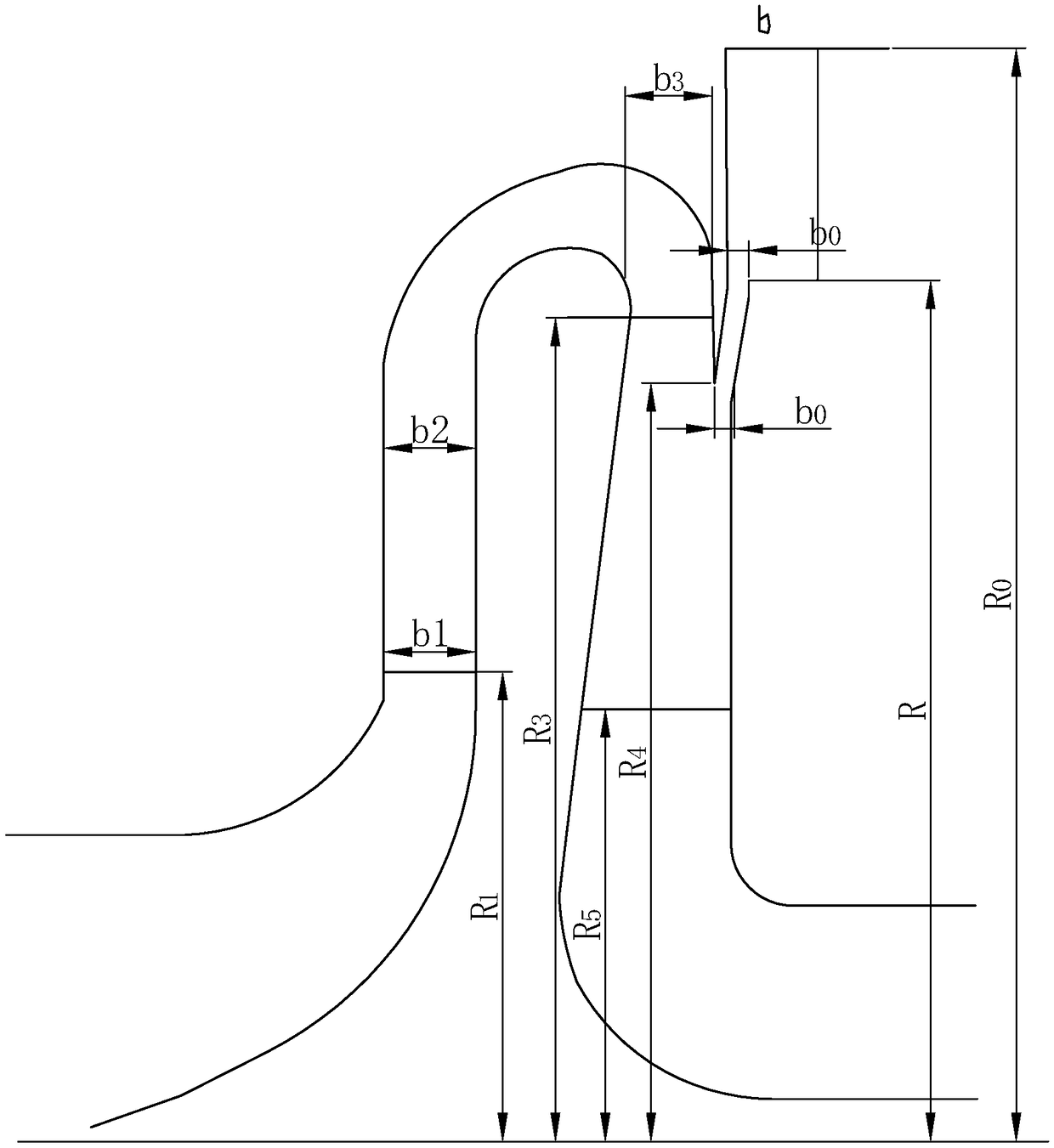

[0032] G max —Maximum gas flow rate (unit: kg / s)

[0033] G 0 —Mass flow rate of main air flow (unit: kg / s)

[0034] G—mass flow rate of aerated gas flow (unit: kg / s)

[0035] R—volute installation height radius (unit: mm)

[0036] R 1 — Radius of the outlet of the previous stage impeller (in mm)

[0037] R 3 — Radius at the inlet of the reflux blade (in mm)

[0038] R 4 —Radius of opening position (unit: mm)

[0039] R 5 —Radius at the outlet of the reflux blade (in mm)

[0040] Re—the radius of the contour line corresponding to any section of the air-filled volute (unit: mm)

[0041] b—Width of the volute chamber of the aerated volute (unit: mm)

[0042] b 1 —Impeller outlet width (mm)

[0043] b 2 —Curve entrance width (in mm)

[0044] b 0 —Width of filling channel (in mm)

[0045] b 4 —Width of the reflux at the filling op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com