Wide-domain supersonic inlet passage based on plasma flow control

A supersonic inlet and flow control technology, which is applied to the combustion of the intake port of the power unit, the layout/installation of the power unit, and the power unit on the aircraft, can solve the problem of single research and improve the flow field characteristics and structure. Simple, the effect of reducing the design Mach number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing of description, the present invention will be further described.

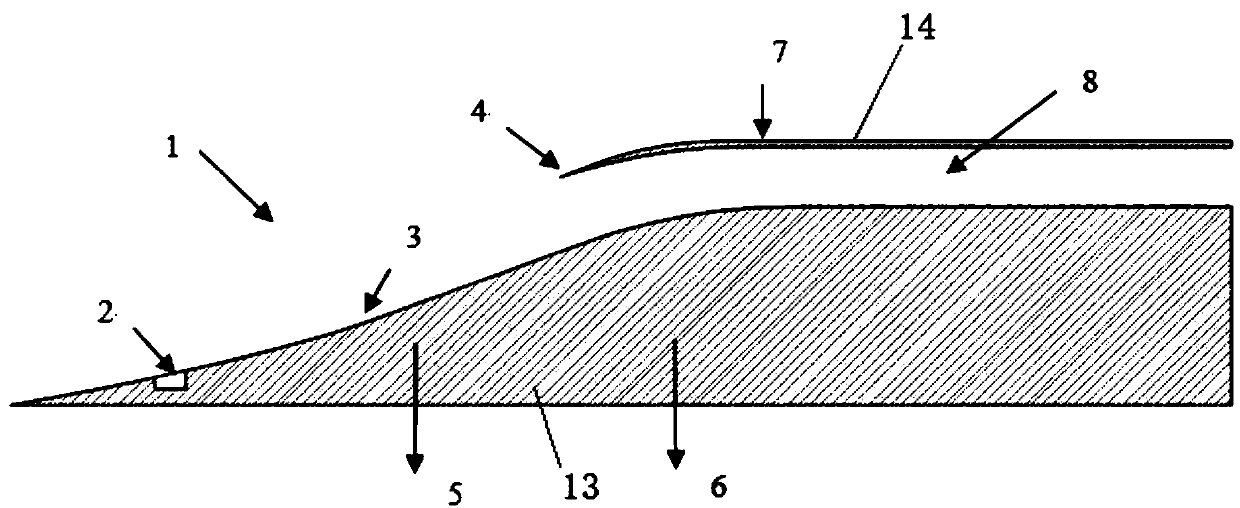

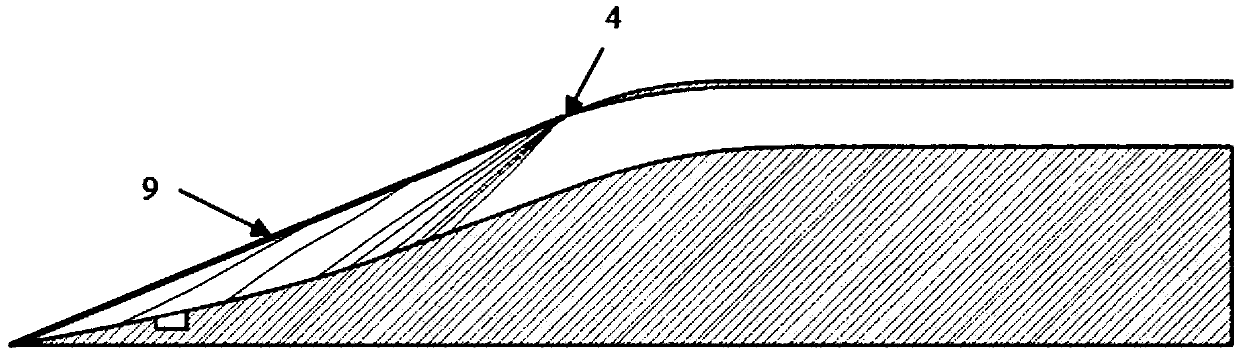

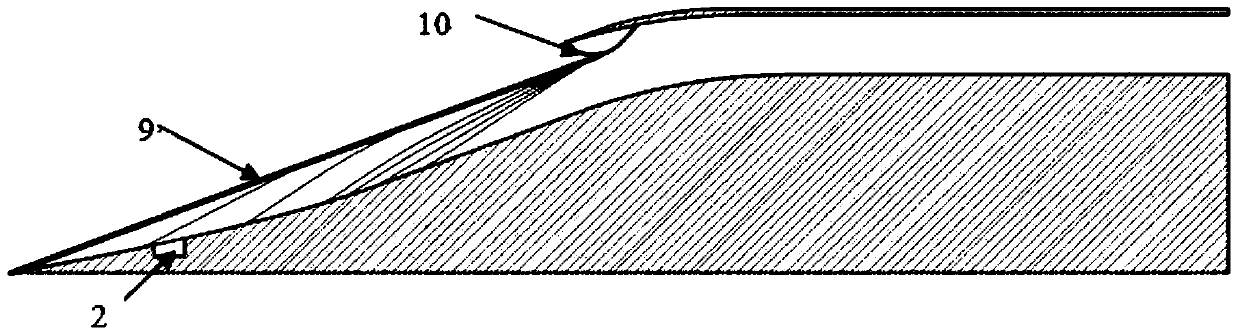

[0019] Such as Figure 1-4 As shown, a wide-velocity supersonic inlet based on plasma flow control includes an inlet main body 13 and a fairing 14 arranged outside the rear part of the inlet main body, and the inlet main body 13 and An intake channel is formed between the fairings 14, and a surface arc discharge plasma excitation device 2 is provided at the front end of the main body of the intake channel.

[0020] The front part of the air inlet main body 13 is a curved wall surface 3 of the air inlet.

[0021] Air inlet lip 4 is formed between the front end of cowl 14 and air inlet main body 13, and air inlet throat 7 is formed between the rear part of the front end of air inlet main body 13 and cowling 14, and the rear end of air inlet main body 13 An air inlet isolation section 8 is formed between the cowling 14 and the rear.

[0022] The part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com