Lower chamber structure of reactor container and reactor container

A reactor vessel and reactor technology, applied in the field of nuclear reactors, can solve problems such as uneven distribution and liquid fuel flow differences, and achieve the effects of accurately matching the core power distribution, avoiding vortices, and having no obvious vortices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

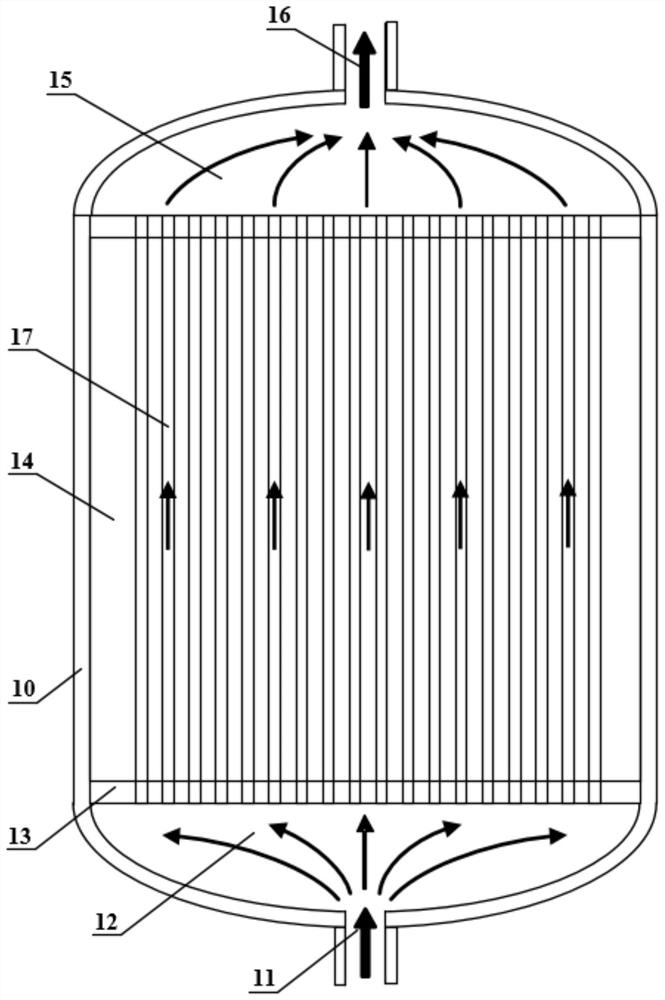

[0060] figure 1 It is a liquid fuel molten salt reactor vessel 10, which includes a reactor lower chamber inlet 11, a reactor lower chamber 12, a core support base plate 13, a reactor core structural member 14, a reactor upper chamber 15, a reactor outlet 16, and a core channel 17.

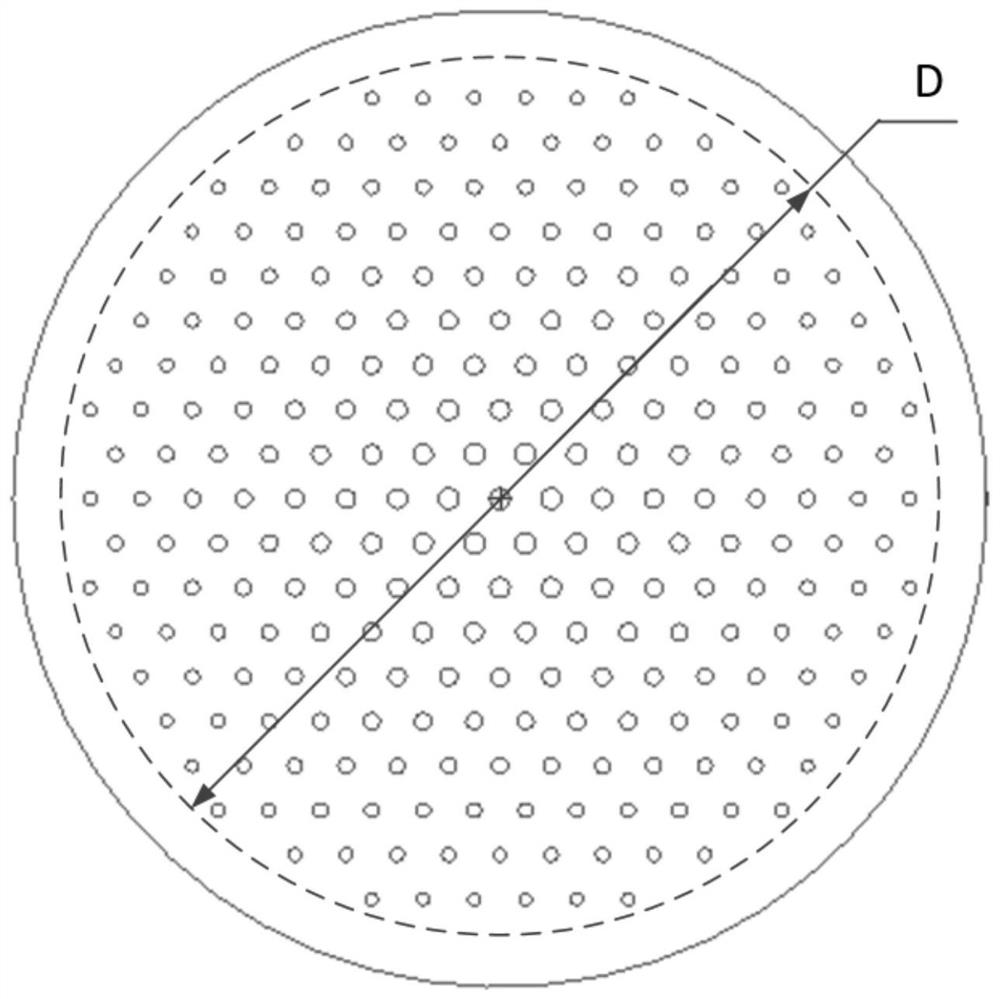

[0061] figure 2 The middle core support bottom plate 13 is fixedly welded on the support member of the inner wall of the reactor vessel 10, and there are perforations corresponding to the positions of the core liquid fuel channels. The size of the perforations can be adjusted in different regions according to the flow distribution requirements. Arranged radially from the center to the periphery, the channels on the same circle have the same size, and the channels on different circles have different sizes (such as figure 2 shown). It is assumed that the diameter of the circular area where holes are distributed on the core support base plate 13 (ie, the circular area where the core channels are...

Embodiment 2

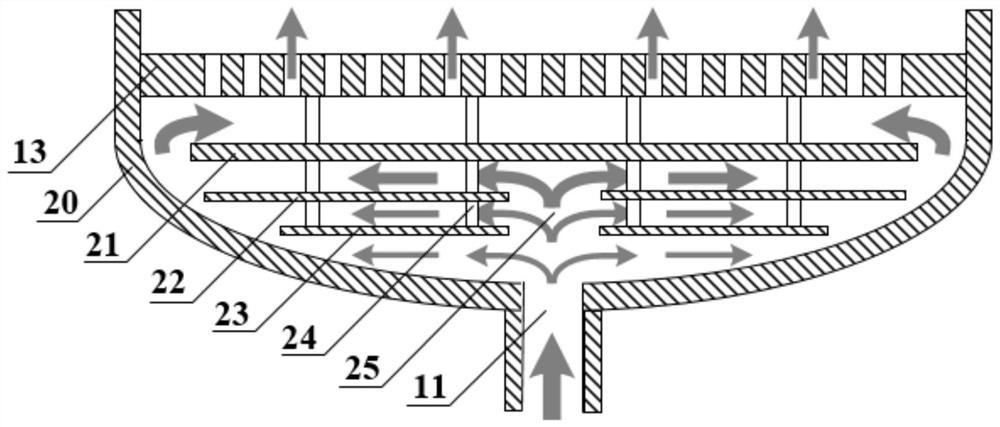

[0066] The structure of the lower chamber in this embodiment is the same as that in Embodiment 1. Assume that the diameter of the circle corresponding to the overall distribution area of the channels on the core support base plate 13 is 1.7m, and the diameter of the core support plate is 1.9m (due to the existence of the core reflection layer, the diameter of the flow channel coverage area of the molten salt reactor core is generally smaller than that of the entire core. diameter, such as image 3 As shown), the reactor lower chamber 12 is a semi-ellipsoid structure, and the diameter of the reactor lower chamber inlet 11 is 0.15m.

[0067] The thickness of the flow distribution plate circular plate 21 is 0.02m, the diameter is 1.7m, and the vertical distance between the upper surface of the flow distribution plate circular plate 21 and the lower surface of the core support bottom plate 13 is 0.08m. The vertical distance between the lower surface of the flow distribution p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com