Proportional cartridge valve with variable flow gain

A proportional cartridge valve and variable flow technology, used in fluid pressure actuation devices, servo motor components, mechanical equipment, etc., can solve the problem of shortening the service life of hydraulic presses and valves, difficult to ensure linear flow gain, and large pressure and flow impact. and other problems to achieve the effect of improving the flow field characteristics, reducing the vortex area, reducing the pressure shock and the sudden change of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

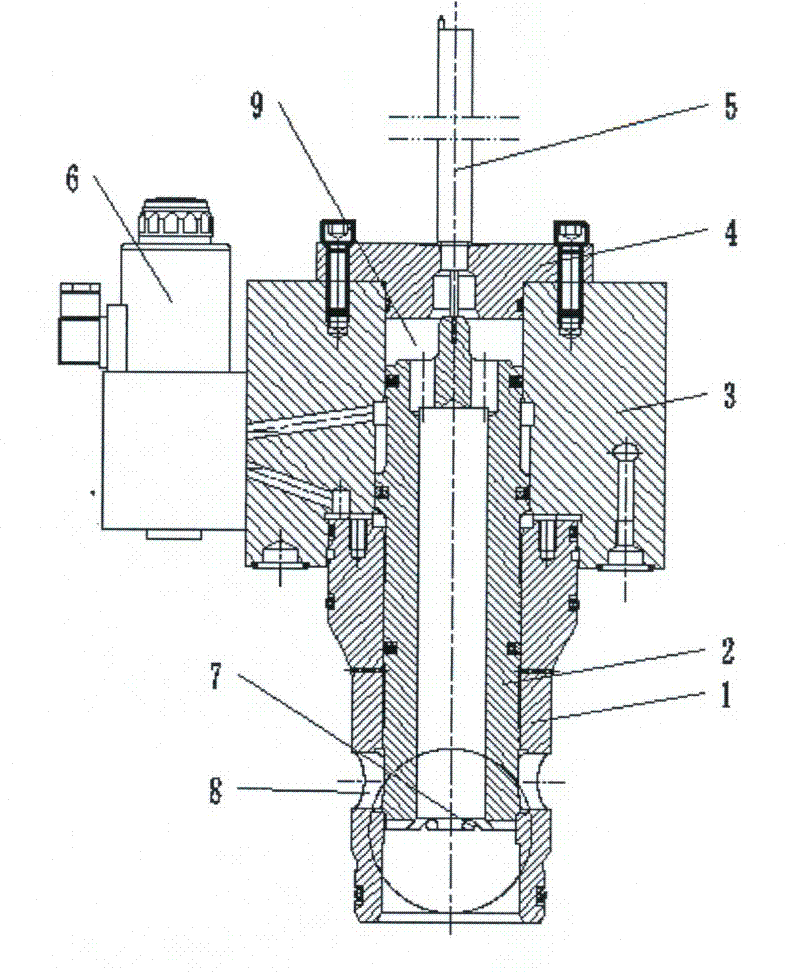

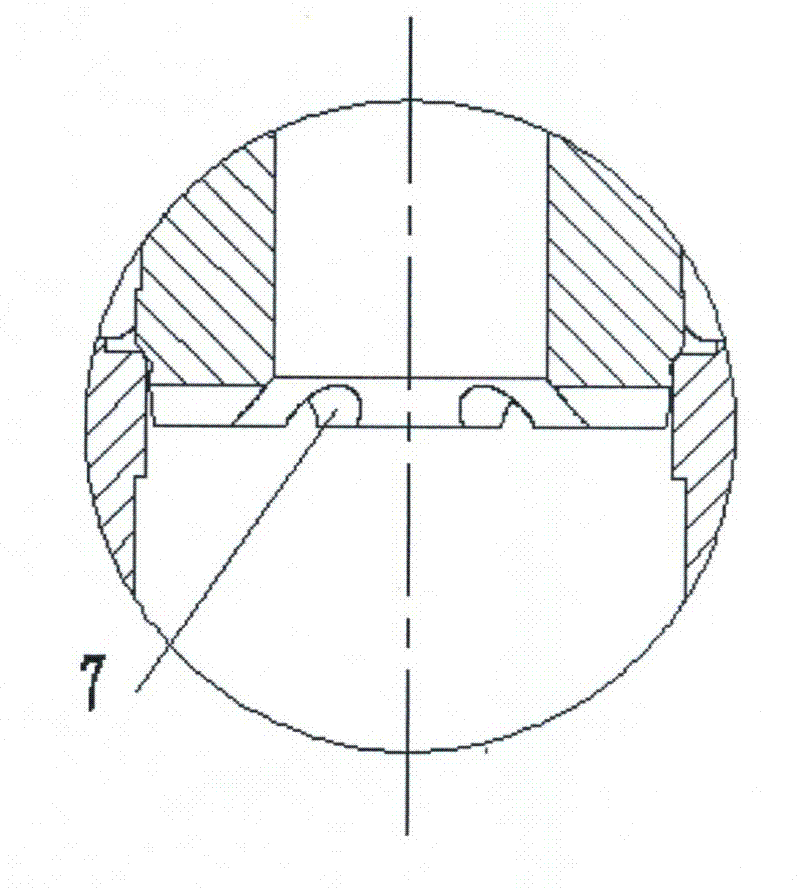

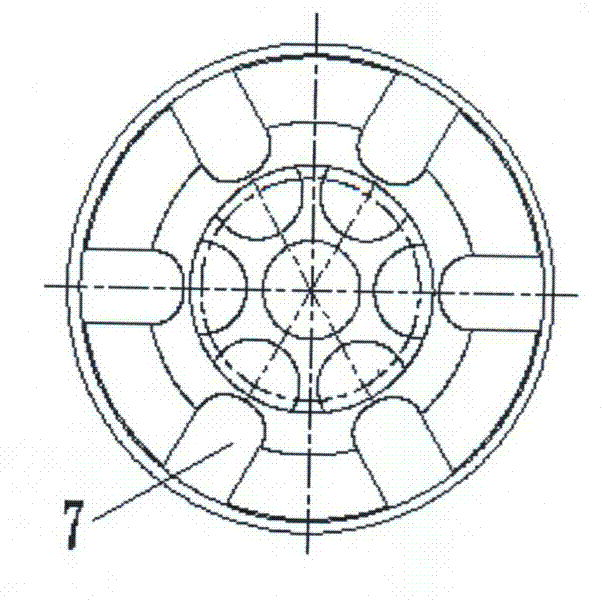

[0015] exist figure 1 In the structural diagram of the proportional cartridge valve with variable flow gain shown, the lower part of the hollow valve core 2 is inside the valve sleeve 1, the lower part of the hollow valve core is sealed with the valve sleeve line, and the upper part of the hollow valve core is matched with the control cover plate 3. The control cover The top of the plate is connected to the bonnet 4, which has a threaded hole, the displacement sensor 5 is fixedly installed on the threaded hole of the bonnet, and the pilot control valve 6 is installed on the side of the control cover plate; a semicircular hole is processed on the port at the bottom of the valve core 7. Make the lower port at the bottom of the valve core a throttling port; four symmetrical waist-shaped holes 8 are arranged on the valve sleeve.

[0016] The working method of the present invention is: the oil flows in from the lower port of the valve core and flows out through the four waist-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com