Device and method for batch preparation of blended yarn with electrostatic spinning nanofiber composite short fiber network

A nanofiber, electrospinning technology, applied in fiber processing, yarn, textiles and papermaking, etc., can solve the problems of easy wear and tear during nanofiber processing and use, disordered nanofiber deposition, etc., to achieve good industrial application prospects, good nanofiber Fiber distribution uniformity, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

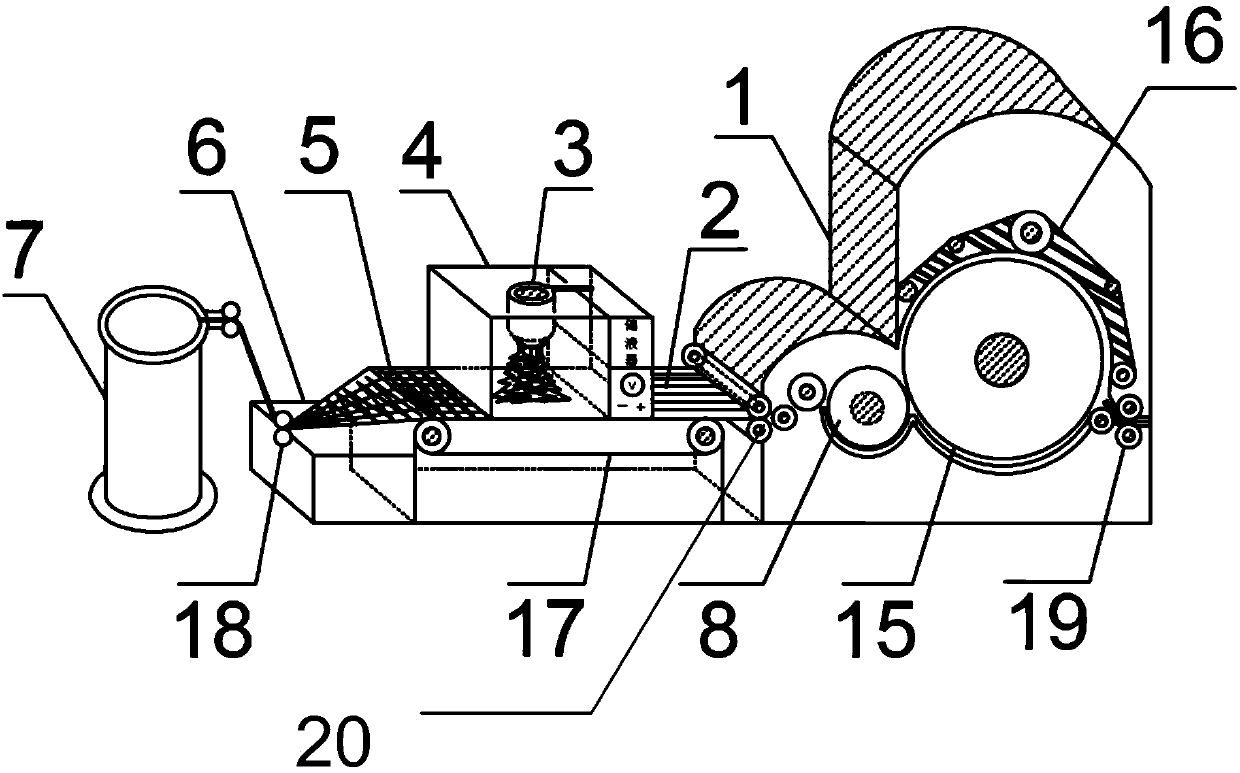

[0036]This embodiment provides a device for preparing blended yarns in batches by electrospinning nanofiber composite staple webs. A conveyor belt 17 is arranged on one side of the carding machine 1, and an electrospinning device 4 is arranged on the conveyor belt 17. The other side of the belt 17 is provided with a bell mouth fixing device 6, a bell mouth 18 is set on the bell mouth fixing device 6, and a bar can 7 is set on the other side of the bell mouth fixing device 6; wherein the electrospinning device 4 is provided with a suspension Downward spinning nozzle 3.

[0037] Described carding machine 1 comprises cotton feeding roller 19, doffer 8, cylinder 15, cover plate 16 and fiber web output roller 20, and the nip of fiber web output roller 20 is positioned at the same level as conveying belt 17.

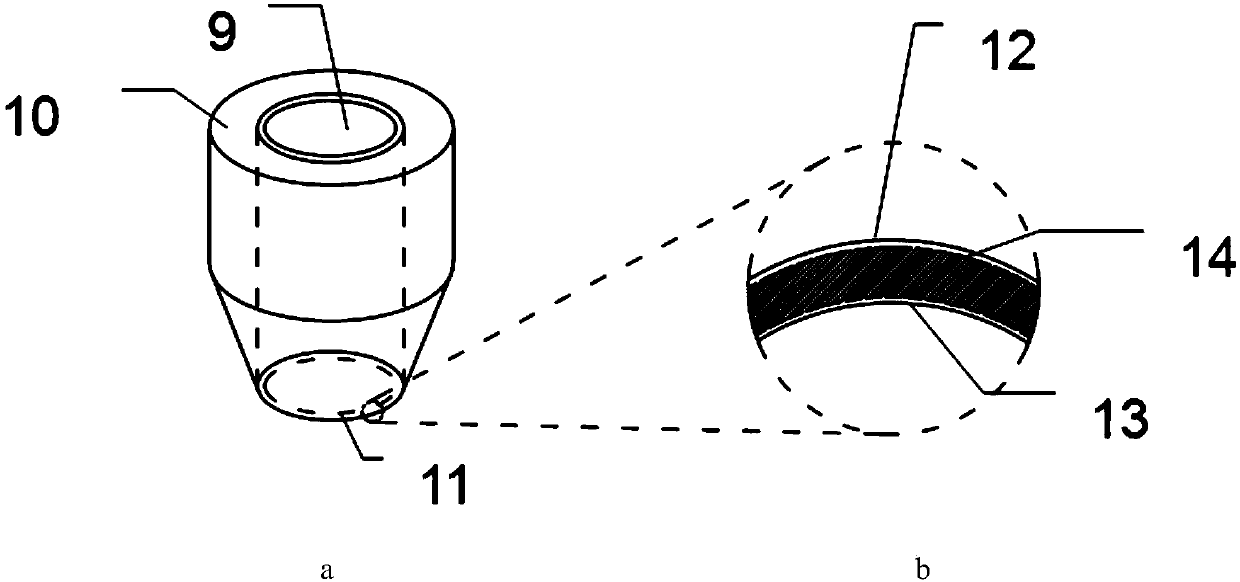

[0038] The suspended downward spinning nozzle 3 is a positive slit liquid control device, including a solid cylinder 9, a hollow cylinder 10 and a round table nozzle 11, where...

Embodiment 2

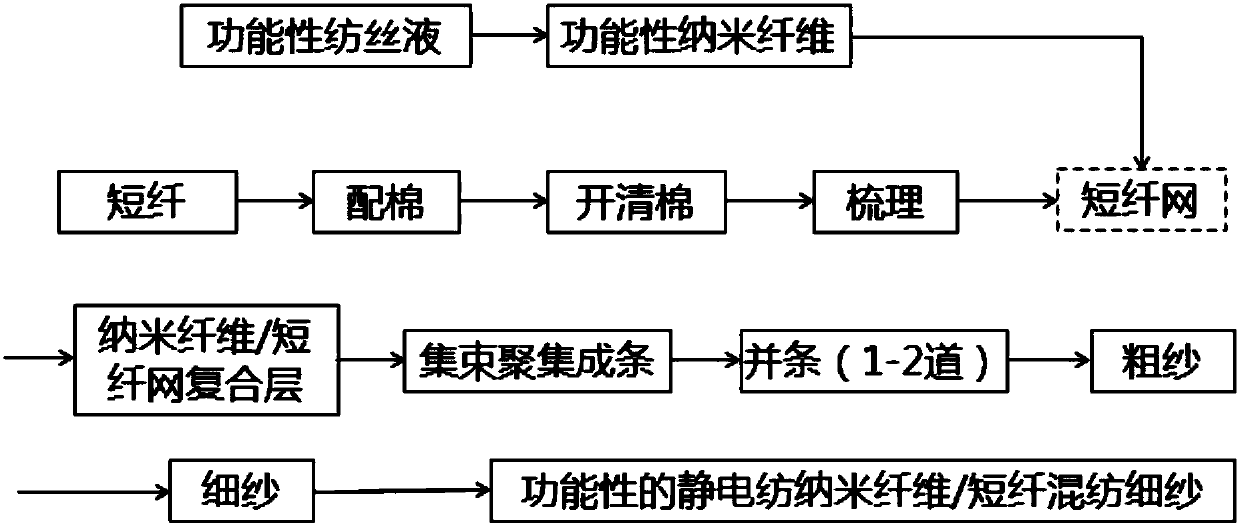

[0042] This embodiment provides a method for preparing blended yarns in batches by electrospinning nanofiber composite staple fiber webs, and the specific steps are as follows:

[0043] (1) 10g polyacrylonitrile (molecular weight is 78000) is dissolved in 85g DMF, adds 5g triclosan antibacterial agent, stirs evenly in magnetic stirrer, obtains that antibacterial agent concentration is 5wt%, polyacrylonitrile concentration is 10wt% uniform spinning solution.

[0044] (2) Mix cotton staple fiber with cotton, open and clean the cotton to obtain a fiber roll, feed the fiber roll into the carding machine 1 by the cotton feeding roller 19, comb through the cylinder 15, the cover plate 16 and the doffer 8, and output it from the fiber web The rolls 20 are output and the staple fiber web 2 is formed on the transfer belt 17 .

[0045] (3) Add the spinning liquid in the step (1) to the electrospinning device 4 for hanging spinning from top to bottom, the applied voltage is 60kv, the di...

Embodiment 3

[0049] This embodiment provides a method for preparing blended yarns in batches by electrospinning nanofiber composite staple fiber webs, and the specific steps are as follows:

[0050] (1) 10g polyacrylonitrile (molecular weight is 78000) is dissolved in 89.5g DMF, adds 0.5g nano-zinc oxide, stirs in magnetic stirrer, obtains that nano-zinc oxide concentration is 0.5wt%, polyacrylonitrile concentration is 10 wt% homogeneous spinning solution.

[0051] (2) Mix viscose staple fiber with cotton, open and clean the cotton to obtain a fiber roll, feed the fiber roll into the carding machine 1 by the cotton feeding roller 19, and comb through the cylinder 15, the cover plate 16 and the doffer 8, and form the fiber web The output roller 20 outputs and forms the staple fiber web 2 on the conveying belt 17 .

[0052] (3) Add the spinning liquid in the step (1) to the electrospinning device 4 for hanging spinning from top to bottom, the applied voltage is 60kv, the distance between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com