Method for improving performance of sintered neodymium-iron-boron magnet

A neodymium-iron-boron and magnet technology, used in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of ineffective coercive force improvement and narrow application range, and achieve high coercivity, Wide range of applications, reducing the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

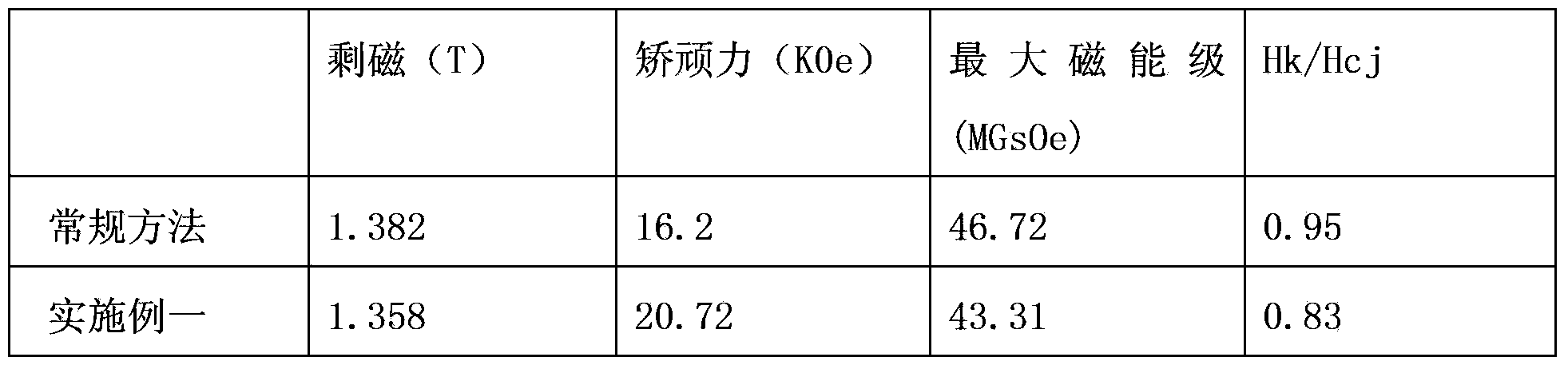

Embodiment 1

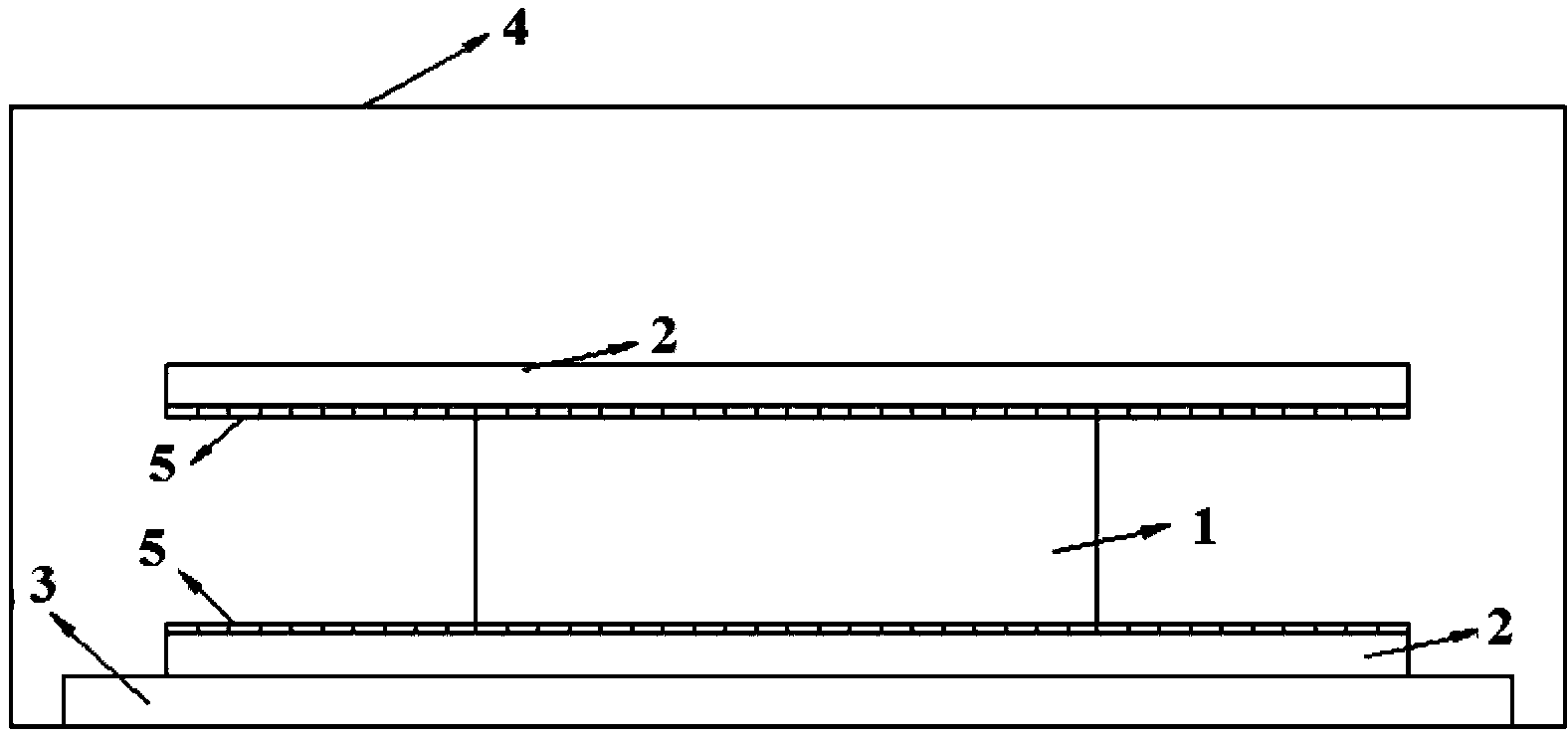

[0025] Embodiment one: a kind of method improving the performance of sintered NdFeB magnet, comprises the following steps:

[0026] ① Preparation of sintered NdFeB magnet green body 1; Sintered NdFeB magnet green body 1 is prepared by casting, hydrogen crushing, jet milling, orientation and molding. The orientation magnetic field is 1.6T, and the isostatic pressure is 200MPa. Press for 10 seconds, the density of sintered NdFeB magnet green body 1 is 3.6g / cm 3 , the thickness is 10mm;

[0027] ②Preparing two massive heavy rare earth 2, the heavy rare earth 2 is massive heavy rare earth Dy;

[0028] ③Under the protection of an inert gas, first place a separation plate 3 on the bottom of the evaporation diffusion box 4, and then place two pieces of heavy rare earth 2, sintered NdFeB magnet green body 1 and two isolation nets 5 up and down on the separation plate 3, wherein the sintered NdFeB magnet green body 1 is located between two pieces of heavy rare earth 2, and the two pi...

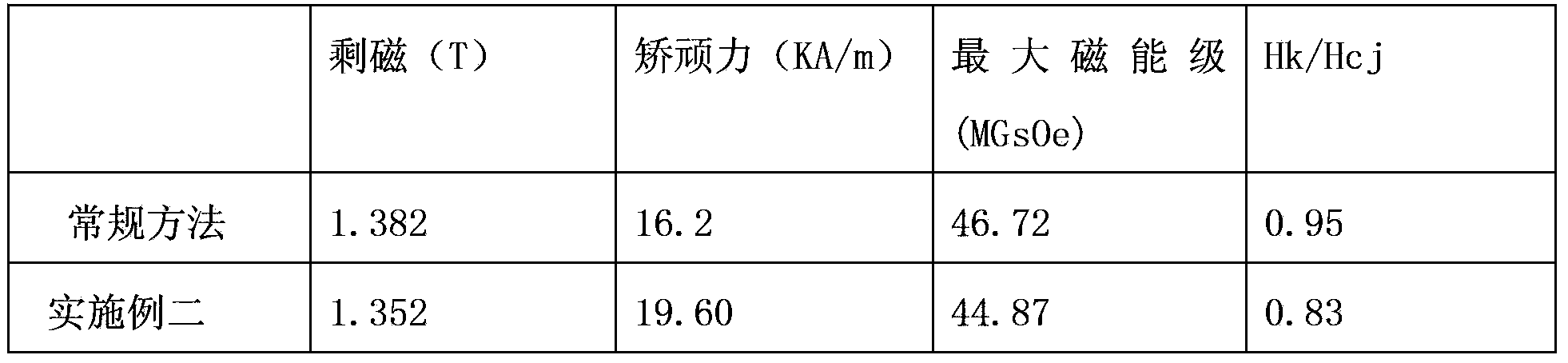

Embodiment 2

[0036] Embodiment two: a kind of method that improves the performance of sintered NdFeB magnet, comprises the following steps:

[0037] ① Preparation of sintered NdFeB magnet green body 1; Sintered NdFeB magnet green body 1 is prepared by casting, hydrogen crushing, jet milling, orientation and molding. The orientation magnetic field is 1.4T, and the isostatic pressure is 140MPa. Press for 10 seconds, the density of sintered NdFeB magnet green body 1 is 4g / cm 3 , the thickness is 40mm;

[0038] ②Preparing two massive heavy rare earth 2, the heavy rare earth 2 is massive heavy rare earth Dy;

[0039] ③Under the protection of an inert gas, first place a separation plate 3 on the bottom of the evaporation diffusion box 4, and then place two pieces of heavy rare earth 2, sintered NdFeB magnet green body 1 and two isolation nets 5 up and down on the separation plate 3, wherein the sintered NdFeB magnet green body 1 is located between two pieces of heavy rare earth 2, and the two ...

Embodiment 3

[0047] Embodiment three: a method for improving the performance of sintered NdFeB magnets, comprising the following steps:

[0048] ① Preparation of sintered NdFeB magnet green body 1; Sintered NdFeB magnet green body 1 is prepared by casting, hydrogen crushing, jet milling, orientation and molding. The orientation magnetic field is 1.6T, and the isostatic pressure is 200MPa. Press for 10 seconds, the density of sintered NdFeB magnet green body 1 is 3.8g / cm 3 , the thickness is 10mm;

[0049] ② Prepare two massive heavy rare earths 2, and the heavy rare earth 2 is massive heavy rare earth Tb;

[0050] ③Under the protection of an inert gas, first place a separation plate 3 on the bottom of the evaporation diffusion box 4, and then place two pieces of heavy rare earth 2, sintered NdFeB magnet green body 1 and two isolation nets 5 up and down on the separation plate 3, wherein the sintered NdFeB magnet green body 1 is located between two pieces of heavy rare earth 2, and the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com