In-pile flow distribution device of reactor of nuclear power station

A flow distribution device and nuclear power plant reactor technology, applied in the field of nuclear power, can solve the problems that the eddy current cannot be fully mixed and cannot be effectively suppressed, and achieves the effects of good flow distribution uniformity, simple structure, and good distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

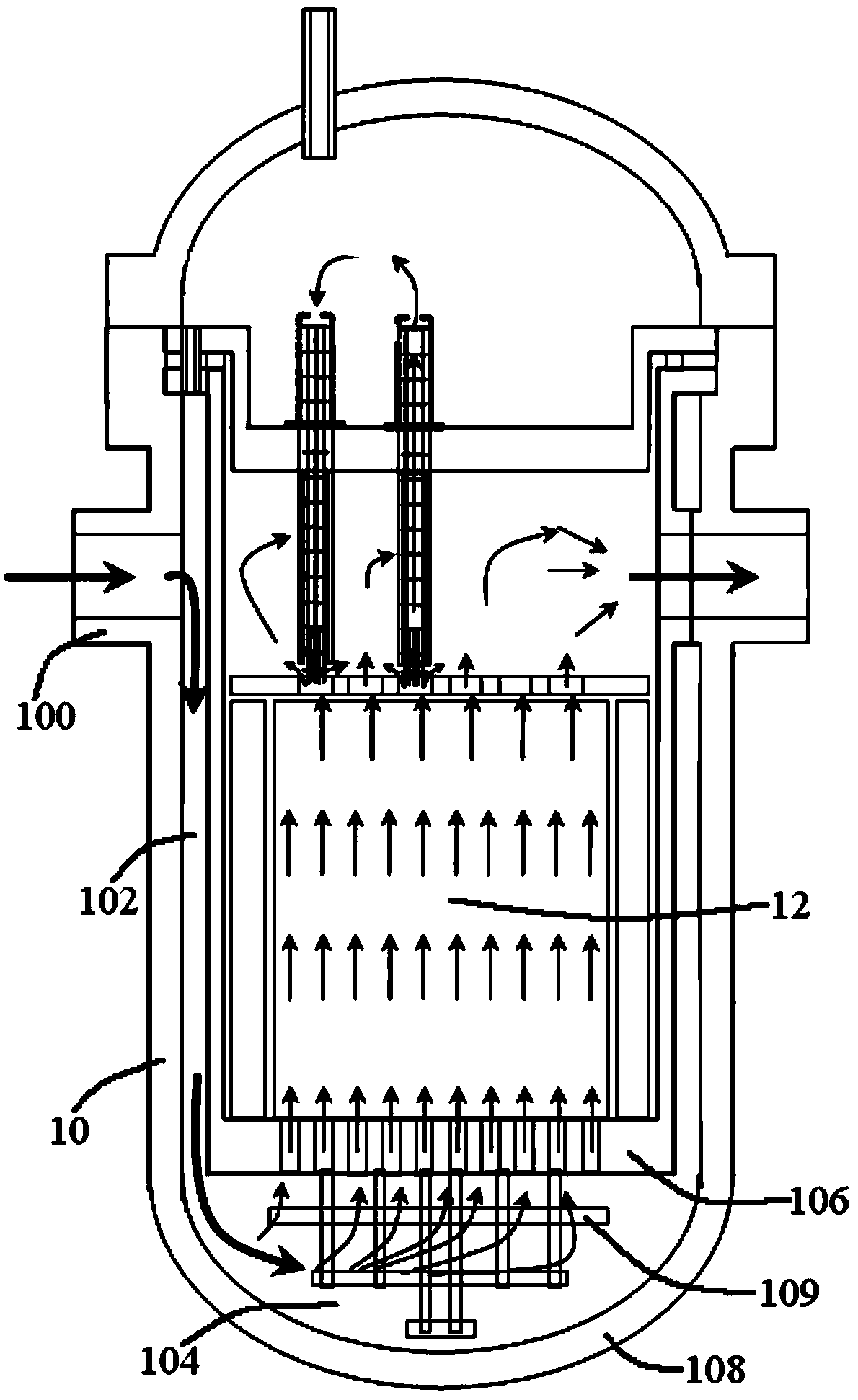

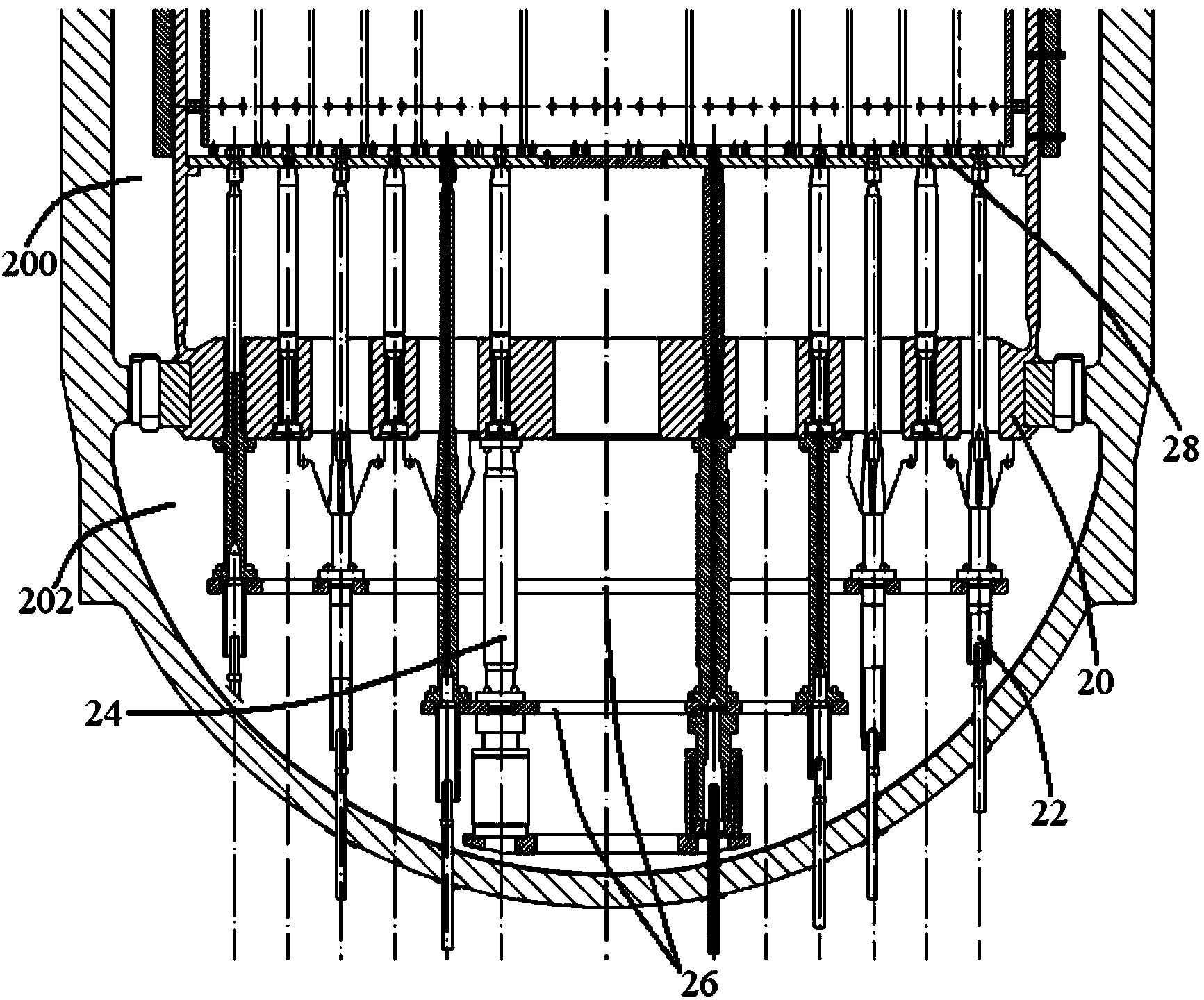

[0027] see Figure 6 and Figure 7 , the reactor flow distribution device of the nuclear power plant reactor of the present invention is installed in the lower head 90 of the pressure vessel, which includes the lower support plate 60 of the core, the surrounding basket structure, the column 80 and the energy absorber 82 . Wherein, the lower support plate 60 of the core is welded to the lower end of the hanging basket 92; The lower chamber is divided into inner and outer parts; the column 80 is vertically arranged between the basket-shaped structure and the lower support plate 60 of the core; the energy absorber 80 is installed under the basket-shaped structure.

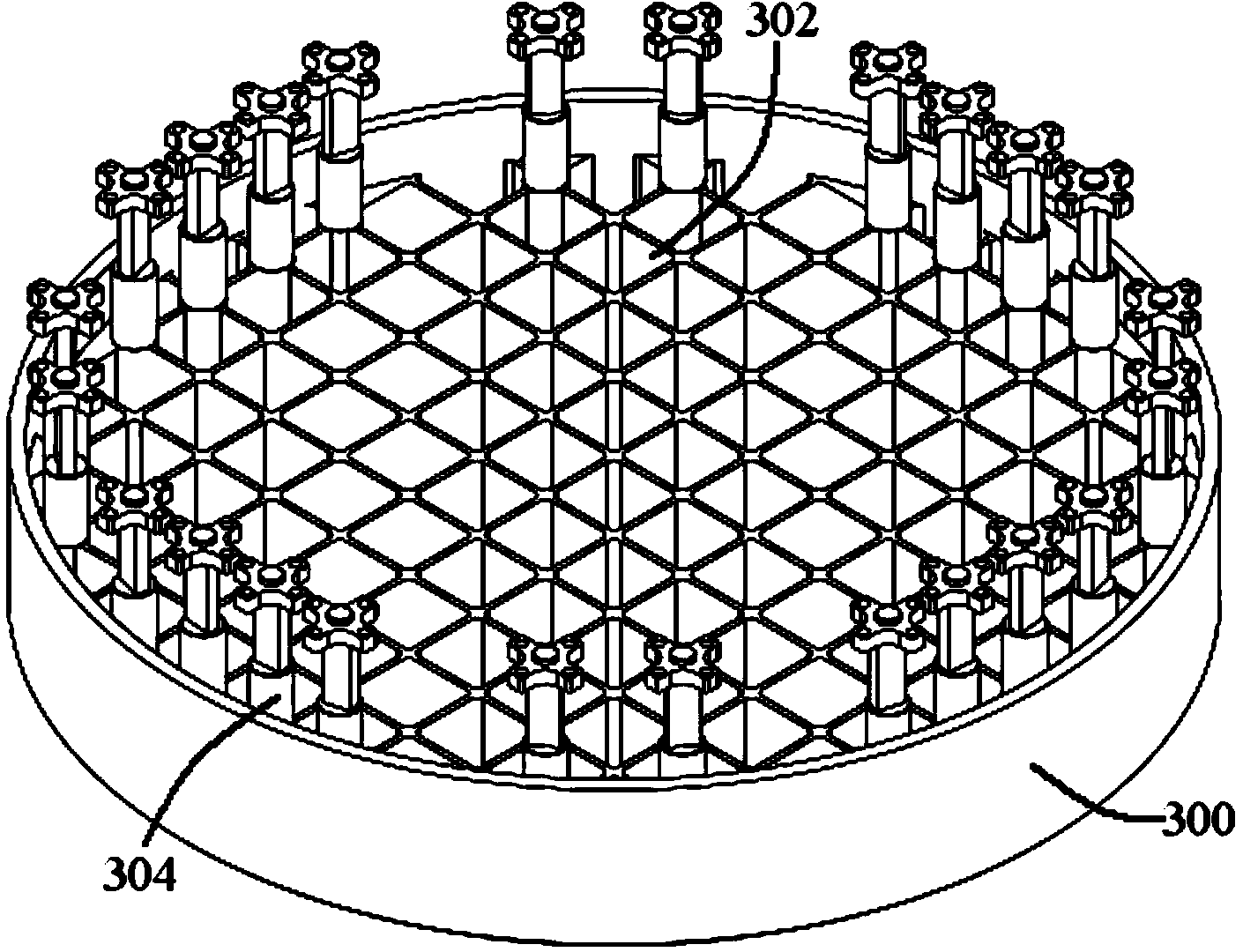

[0028] Perforations 62 are opened on the lower support plate 60 corresponding to the position of each group of fuel assemblies.

[0029] The basket-shaped structure is fixed below the core lower supporting plate 60, and its thickness is between 30 and 100 mm. The structure includes a porous surrounding basket 72, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com