Blasting method of driving, mining and cutting drift under ultrahard fault

A technology of faults and conditions, applied in the field of blasting, can solve problems such as failure to achieve light blasting, uneven cross-section, waste of man-hours, etc., and achieve the effect of reducing blasting resistance and improving blasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

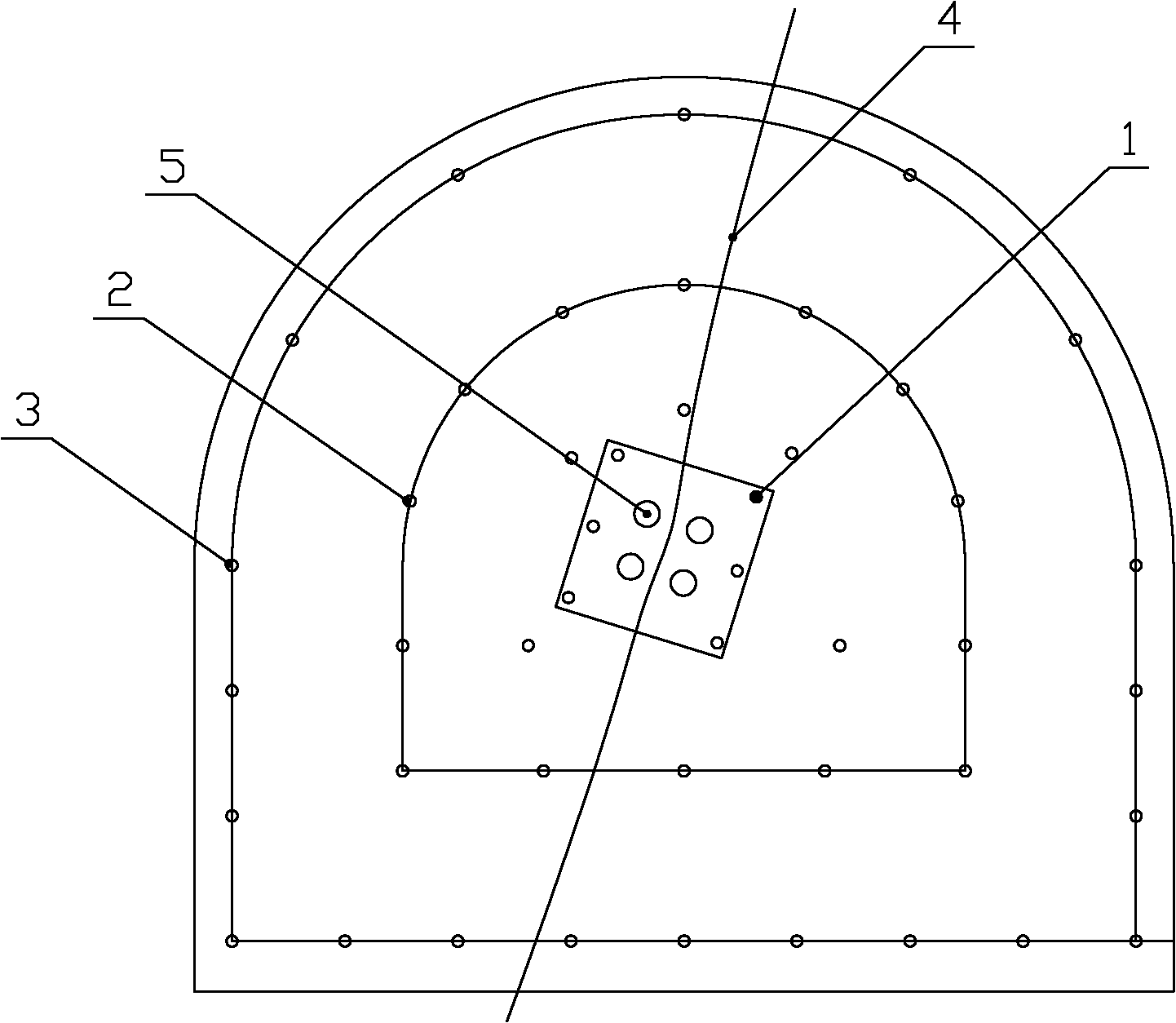

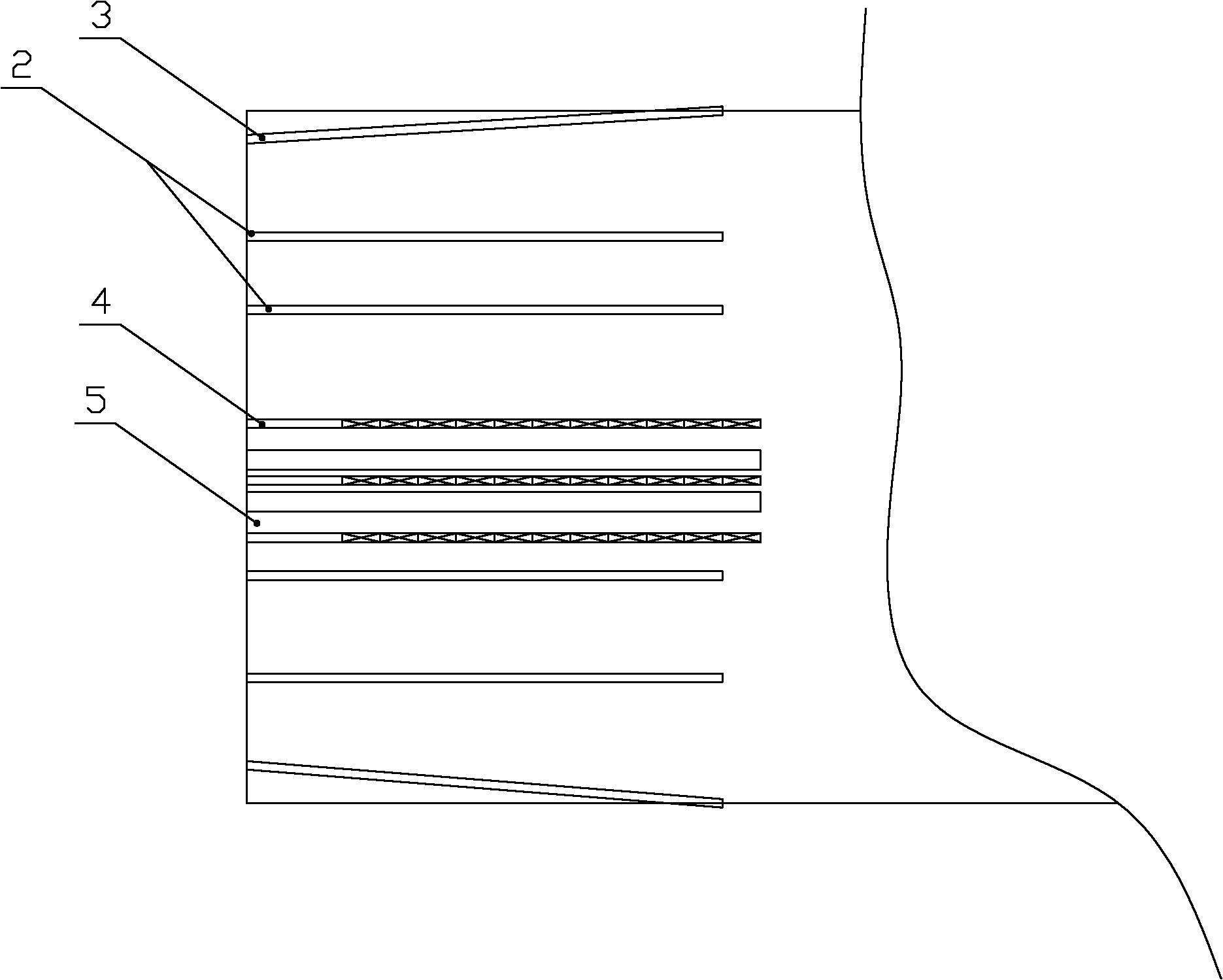

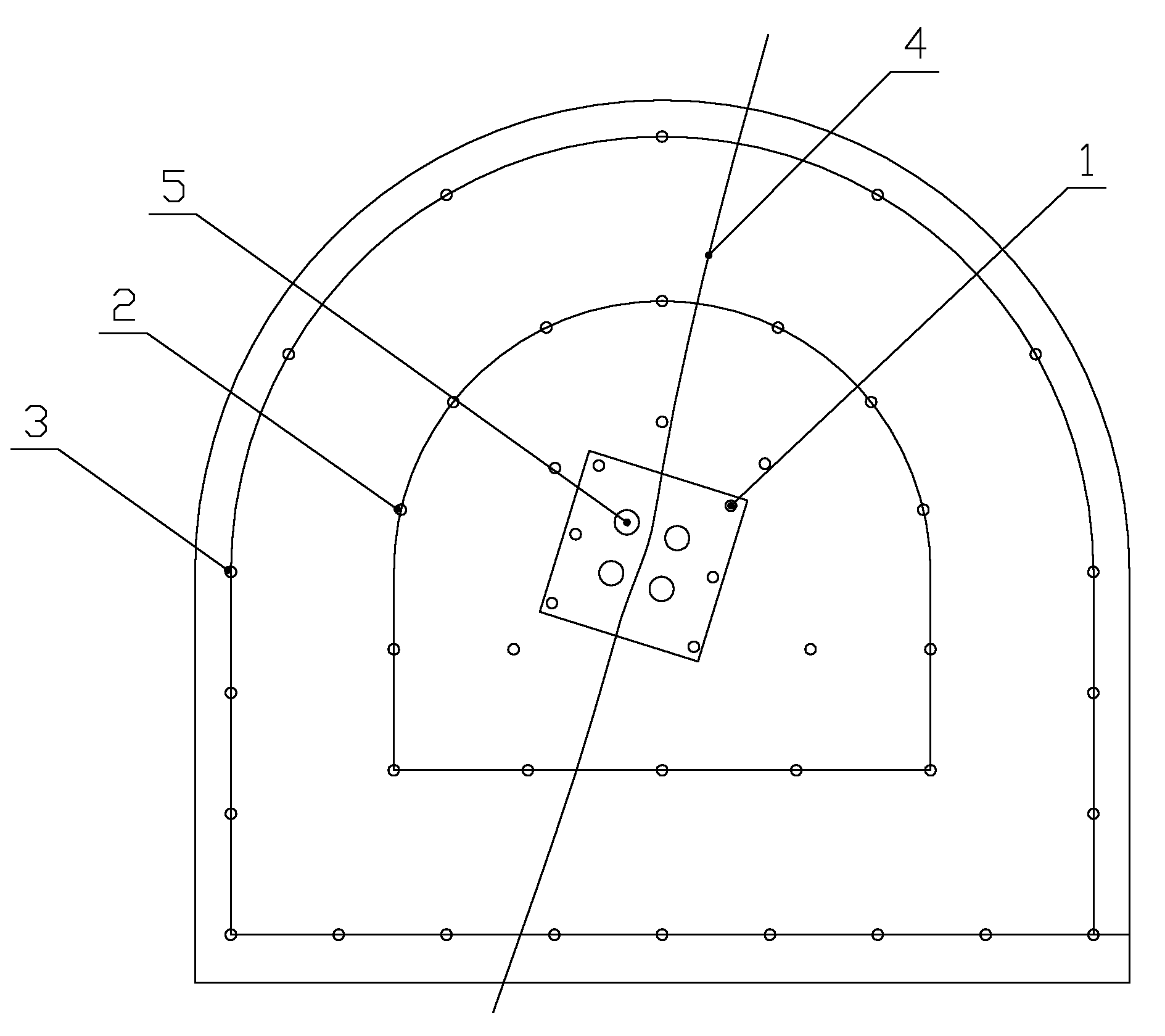

[0021] Such as figure 1 and figure 2 As shown, the blasting method of driving and cutting roadway under extremely hard fault conditions of the present invention comprises the following steps:

[0022] a. Drill the blast hole blasthole 1 arranged on both sides of the fault plane 4; the blast hole blast hole 1 in step a, the auxiliary blast hole 2 and the peripheral blast hole 3 in step d all use the single-arm jumbo Rock Bomer281 for rock drilling drill set.

[0023] b. Arrange detonators and explosives in the blast hole;

[0024] c, detonate the detonator arranged in the detonation chamber blast hole, explosives to obtain the detonation chamber; after the detonation chamber is obtained by blasting, remove the residue in the detonation chamber, so that after steps a to c, a free blasting space is obtained (i.e. The formed detonation chamber), thus p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com