Digital electronic detonator hole-by-hole detonating network and blasting delay scheme thereof

A digital electronic detonator and hole-by-hole technology, which is applied in the field of blasting, can solve the problems of poor blasting effect of multiple rows and several blastholes, and achieve the best blasting effect, enhance blasting effect, and reduce blasting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

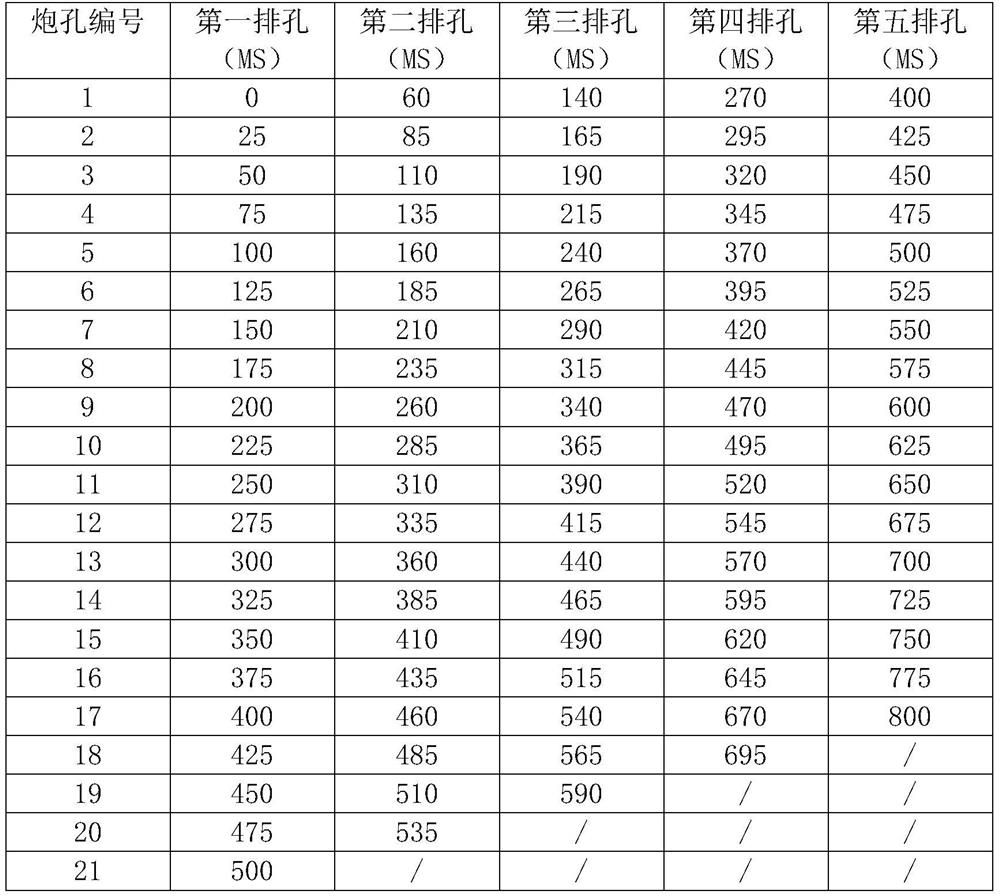

[0027] A digital electronic detonator hole-by-hole detonation network, including 5 rows of blastholes arranged in parallel, each row of blastholes is set as follows: the row spacing is 3.5m, the hole spacing of each row of blastholes is 5.2m, the number of blastholes in the first row The number of blastholes in each row is one less than that of the front row, and the total number of blastholes is 95; the diameter of the blastholes is 90mm, the inclination angle is 75°, and the depth is 15m; each blasthole is equipped with a millisecond delay electric detonator. The minimum resistance line is 3.3m, the charge in linear meters is 8.75kg / m, the packing length is 5.0m, and the maximum charge in a single section is 110kg.

[0028] An equilateral triangle is formed between two adjacent blastholes in each row and one blasthole in the next row, and the hole-by-hole detonation network formed by the arrangement of all the blastholes is an isosceles trapezoid.

[0029] The blasting dela...

Embodiment 2

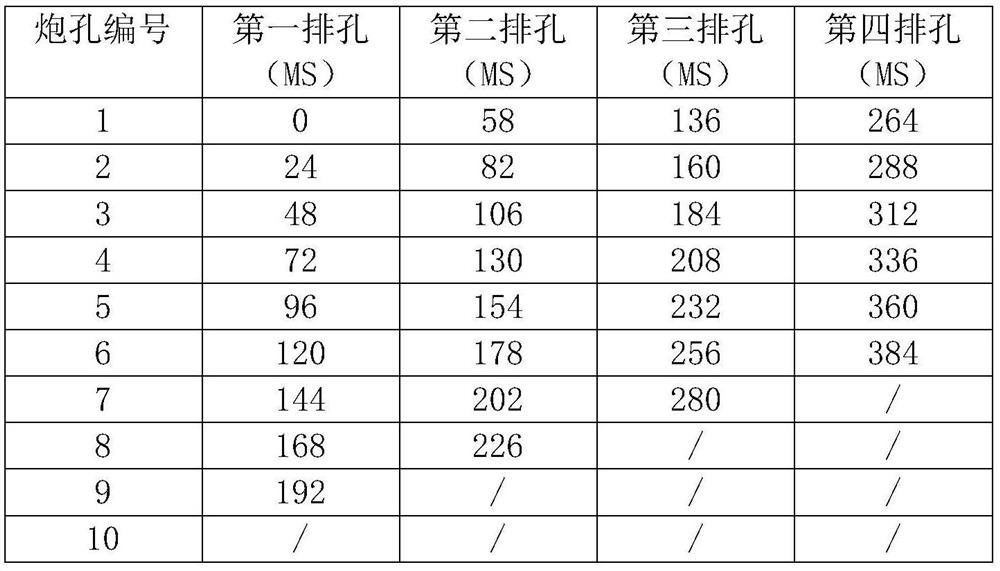

[0034] A digital electronic detonator hole-by-hole detonation network, including 4 rows of blastholes arranged in parallel, each row of blastholes is set as follows: the row spacing is 3.8m, the hole spacing of each row of blastholes is 4.8m, the number of blastholes in the first row The number of blastholes in each row is one less than that of the front row, and the total number of blastholes is 34; the diameter of the blastholes is 95mm, the inclination angle is 70°, and the depth is 12m; each blasthole is equipped with a millisecond delay electric detonator.

[0035] An equilateral triangle is formed between two adjacent blastholes in each row and one blasthole in the next row, and the hole-by-hole detonation network formed by the arrangement of all the blastholes is an isosceles trapezoid.

[0036] The digital electronic detonator hole-by-hole detonation network also includes the following parameters: the minimum resistance line is 3.0m, the charge amount in linear meters ...

Embodiment 3

[0042]A digital electronic detonator hole-by-hole detonation network, including 6 rows of blastholes arranged in parallel, each row of blastholes is set as follows: the row spacing is 3.6m, the hole spacing of each row of blastholes is 5.0m, the number of blastholes in the first row The number of blastholes in each row is one less than that of the front row, and the total number of blastholes is 75; the diameter of the blastholes is 100mm, the inclination angle is 78°, and the depth is 17m; each blasthole is equipped with a millisecond delay electric detonator.

[0043] An equilateral triangle is formed between two adjacent blastholes in each row and one blasthole in the next row, and the hole-by-hole detonation network formed by the arrangement of all the blastholes is an isosceles trapezoid.

[0044] The digital electronic detonator hole-by-hole detonation network also includes the following parameters: the minimum resistance line is 3.4m, the charge per meter is 9.8kg / m, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com