Liquid scattering device and liquid scattering device central tube hog forging process

A technology of throwing devices and central tubes, which is applied in the direction of offensive equipment, ammunition, mechanical equipment, etc., and can solve the problems of reducing the coverage area of clouds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

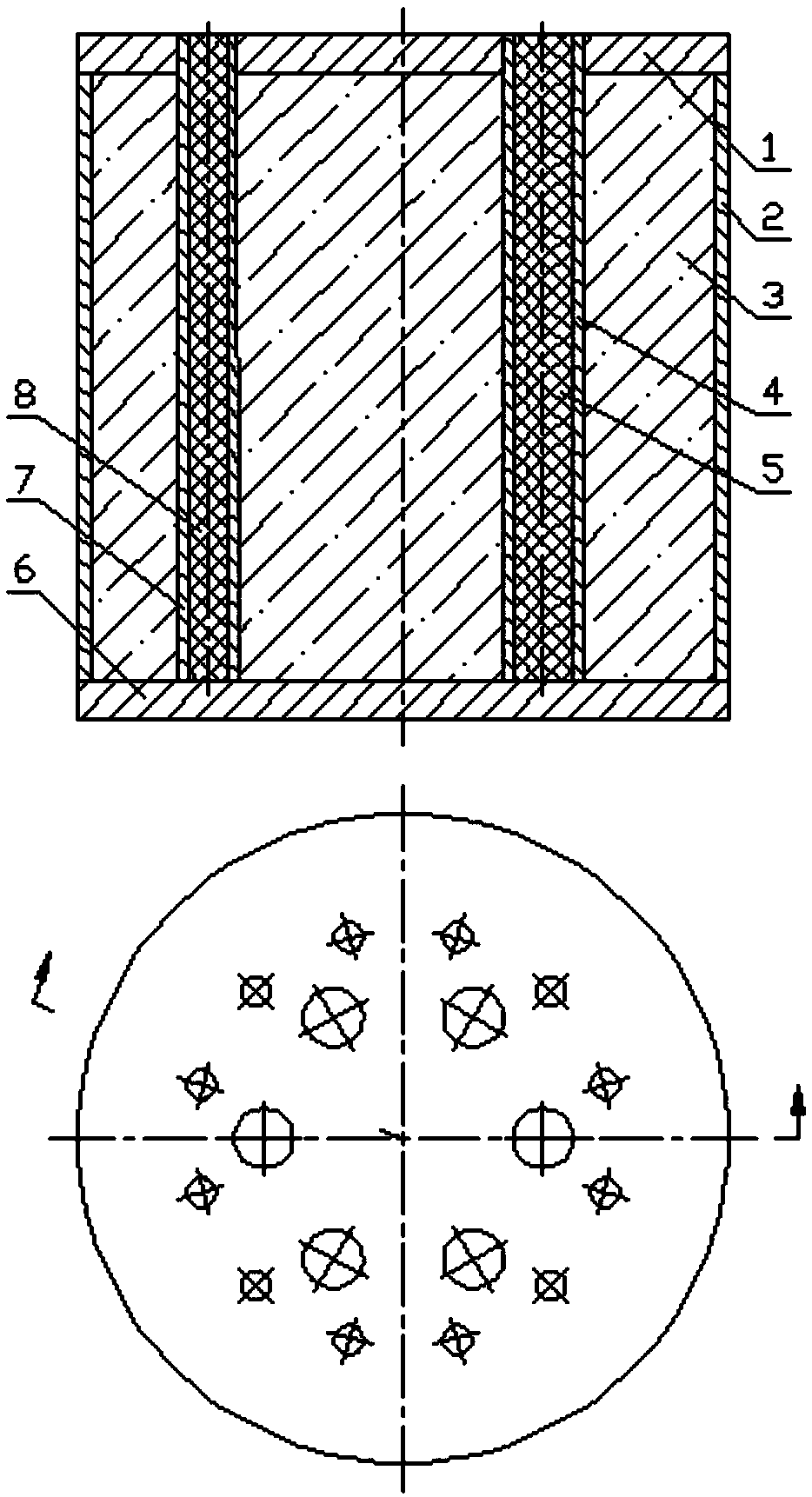

[0081] Such as figure 1 As shown, this embodiment provides a liquid throwing device and its central tube hot forging process, including a shell 2, a liquid 3, a lower end cover 6, and is characterized in that it also includes an upper end cover 1, a first central tube 4, a second The first throwing medicine 5, the second central tube 7, and the second throwing medicine 8;

[0082] The shell 2 is a cylindrical body made of 304 stainless steel with a wall thickness of 2mm; the lower end of the shell 2 is connected with a lower end cover 6, and the shell 2 and the lower end cover 6 are connected by welding. The welding must be reliable, and defects such as crack inclusions are not allowed , need to meet sealing after welding, the lower end cover 6 is a circular plate, the material of the lower end cover 6 is 304 stainless steel, the diameter of the circular plate of the lower end cover 6 is the same as the diameter of the shell 2 cylinder, the lower end cover 6 and the shell 2 ar...

Embodiment 2

[0135] Such as figure 1 As shown, this embodiment provides a liquid throwing device and its central tube hot forging process, including a shell 2, a liquid 3, a lower end cover 6, and is characterized in that it also includes an upper end cover 1, a first central tube 4, a second The first throwing medicine 5, the second central tube 7, and the second throwing medicine 8;

[0136] The shell 2 is a cylindrical body made of 304 stainless steel with a wall thickness of 2mm; the lower end of the shell 2 is connected with a lower end cover 6, and the shell 2 and the lower end cover 6 are connected by welding. The welding must be reliable, and defects such as crack inclusions are not allowed , need to meet sealing after welding, the lower end cover 6 is a circular plate, the material of the lower end cover 6 is 304 stainless steel, the diameter of the circular plate of the lower end cover 6 is the same as the diameter of the shell 2 cylinder, the lower end cover 6 and the shell 2 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com