Pushing plate type scattering device

A throwing device and push plate technology, which is applied in the direction of launching devices, transportation and packaging, and equipment for loading and unloading goods, etc., can solve the problems of large space, unsuitable for tight space, low overload throwing, etc., and achieve high energy utilization rate , Reasonable structure design, low throwing overload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

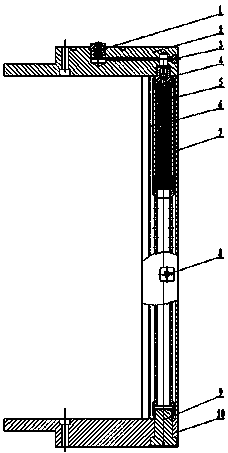

[0037] like figure 1 As shown, a push plate type throwing device includes: a fire contact part 1, a front end plate 2, a sealing screw 3, a fire transmission part 4, a gas generator 5, a push plate 6, a body 7, a pin seat 8, a tension Screw rod 9, rear end plate 10;

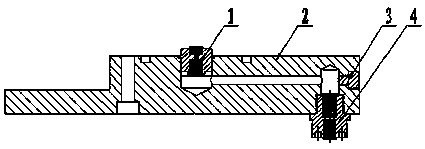

[0038] The threads of the fire-connecting part 1 and the fire-transmitting part 4 are glued and then screwed into the center screw hole on the upper end surface of the front end plate 2 and the outer screw hole on the lower end surface respectively;

[0039] The seal screw 3 thread is screwed into the screw hole on the outside of the front plate 2 after being glued;

[0040] The upper end thread of the gas generator 5 is glued and screwed to the output end of the fire transmission part 4;

[0041] The push plate 6 is connected to the body 7 through the longitudinal anastomosis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com