A double horizontal auger conveying tank for transporting bulk feed or grain

A dual-level, tank conveying technology, applied in the directions of transportation and packaging, packaging, loading/unloading, etc., can solve the problem that the manual opening and discharging system cannot achieve fully automatic control of the whole vehicle, the tank loading capacity can no longer be increased, and the Improve the unloading speed and other issues, to achieve the effect of reasonable overall structure and fixed connection method, convenient switching, loading capacity and unloading speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

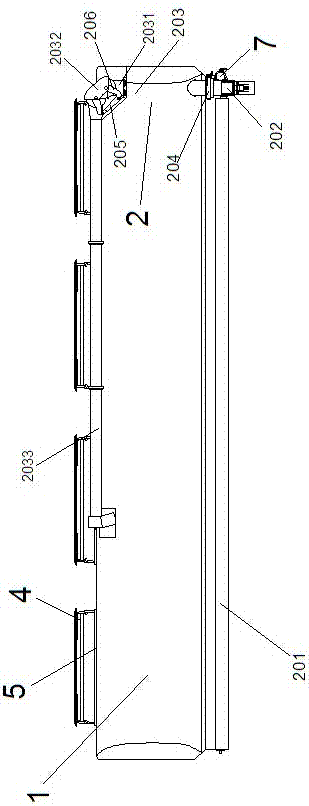

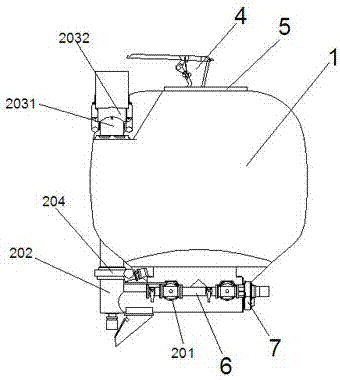

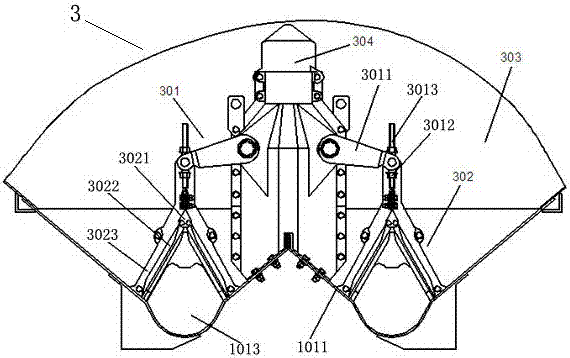

[0030] As shown in the figure, a double-level auger conveying tank for transporting bulk feed or grain is equipped with a double-level auger loading system 2, a door opening and discharging system 3 and a four-link feeding door on the tank body 1 of the conveying tank. Mechanism 4, wherein the material enters the tank body 1 through the four-link feeding door mechanism 4 for storage, and then enters the double-level auger top loading system 2 through the door opening and discharging system 3, and the double-level auger top loading system 2 Discharged to the outside, the double-horizontal auger bodywork system 2 includes a double-horizontal auger shaft assembly 201, a horizontal auger assembly 202 and a vertical lifting auger assembly 203 connected in sequence, wherein the double-horizontal auger shaft assembly 201 is installed on the double horizontal auger pipe 1013 in the tank body 1, its front end is installed on the front lower sealing plate 105 of the tank body 1 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com