Tunneling electron detonator blasting construction method

A construction method and technology of electronic detonators, applied in blasting and other directions, can solve the problems affecting urban traffic, the life and work of surface residents and enterprises and institutions, the impact of construction progress, large blasting vibration, etc., to achieve improved blasting effect and high delay accuracy. , Increase the effect of single-cycle footage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

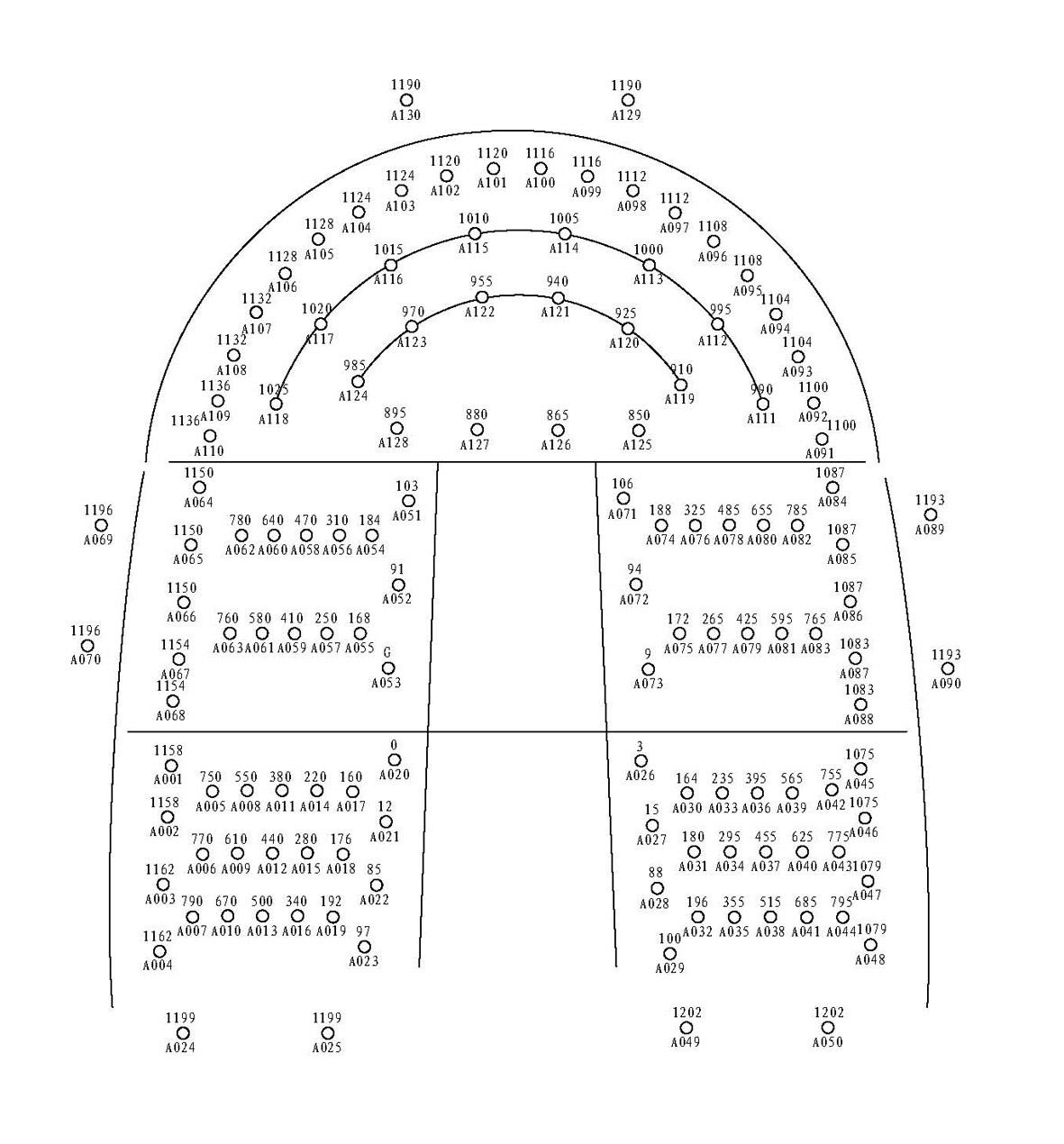

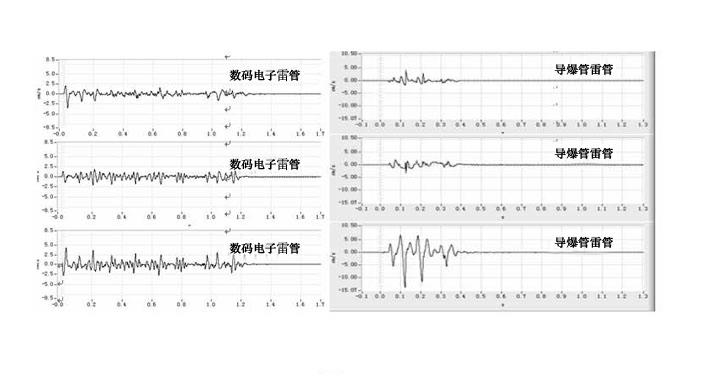

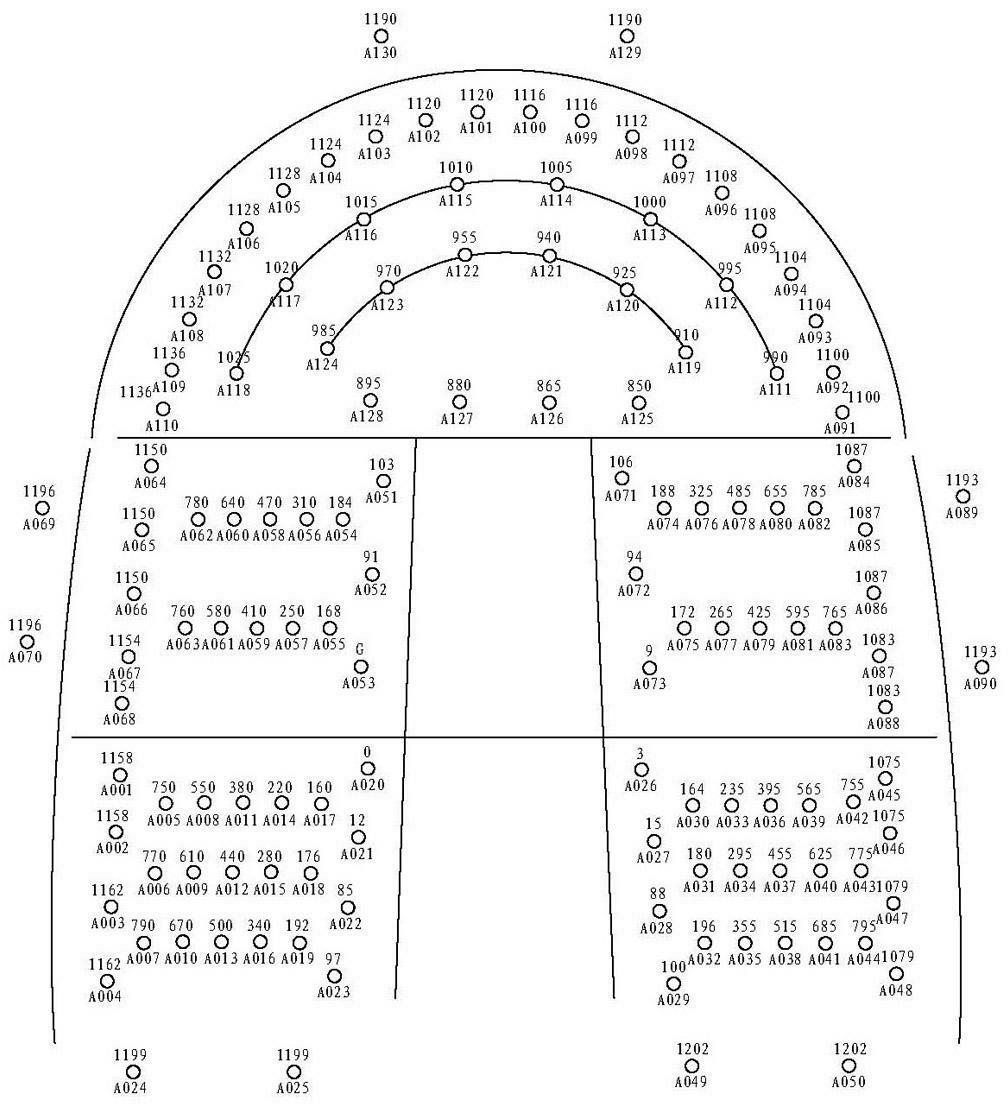

[0017] For urban underground excavation tunnel projects near buildings (structures), limited ground conditions, complex stratum structure, shallow buried depth, and high requirements for safety and construction progress, the digital electronic detonator is programmable in the hole and has high delay accuracy. In the process of tunnel blasting construction, by analyzing the blasting vibration waveform, find out the half-cycle duration of the main vibration frequency, and determine a reasonable blasting delay, so that the blast waves caused by two adjacent blast holes reach the target. The time difference between the time of protecting the building and the wave corresponding to the main vibration frequency is half a period, so that the explosion waves are superimposed on each other in the excavation section, increasing the probability of rock da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com