Electric firing explosive head ignition pressure test method

A test method and pressure test technology, applied in fuzes, weapon accessories, offensive equipment, etc., can solve the problems affecting the delay accuracy of delayed electric detonators, the ignition time of delayed charge, and the combustion speed of the combustion environment pressure, and achieve the effect of improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

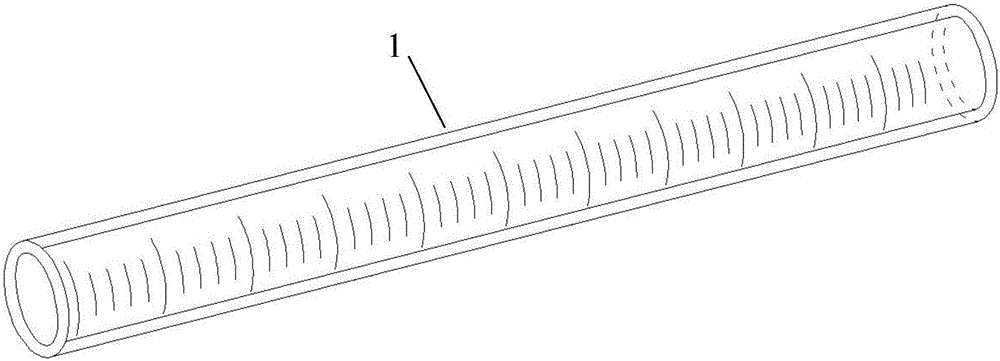

[0071] refer to figure 1 , the test tube 1 is a hollow transparent quartz tube with a length of 550 mm, an inner diameter of 10 mm, and a wall thickness of 1.50 mm. There is a scale line with a measuring range of 550 mm on it, and the adjacent scale value is 1 mm.

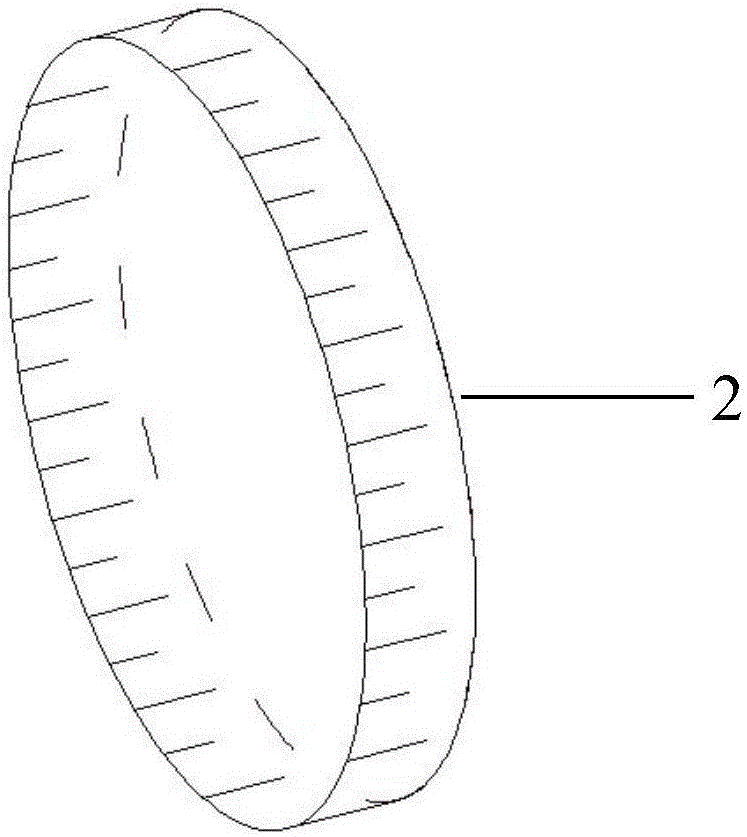

[0072] refer to figure 2 , Flyer 2 is a disc structure, made of colored lightweight high-strength quartz, with a diameter of 9.96 mm and a thickness of 1 mm. There are 360 engraved lines at equal intervals on its side, and the corresponding central angle of two adjacent engraved lines is 1°. The color flyer makes the motion state of the flyer captured by the high-speed camera clearer, which is beneficial to the improvement of measurement accuracy.

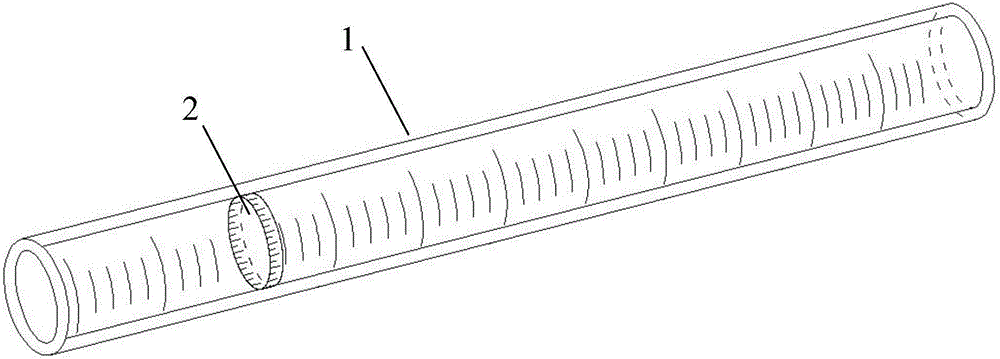

[0073] refer to image 3 , Put the flying piece 2 into the test tube 1, the quartz has high hardness and small friction coefficient.

[0074] refer to Figure 4 , the outer diameter of the fixed plug 4 is 10 mm, and the axis is provided with a hole with an apertu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com