Construction method of tunnel shock relieve hole controlling blasting

A technology for controlling blasting and construction methods, applied in blasting and other directions, can solve problems such as large vibration of upper buildings and pipelines, damage to buildings and pipelines, etc., to reduce damage, reduce blasting vibration speed, and achieve good blasting effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

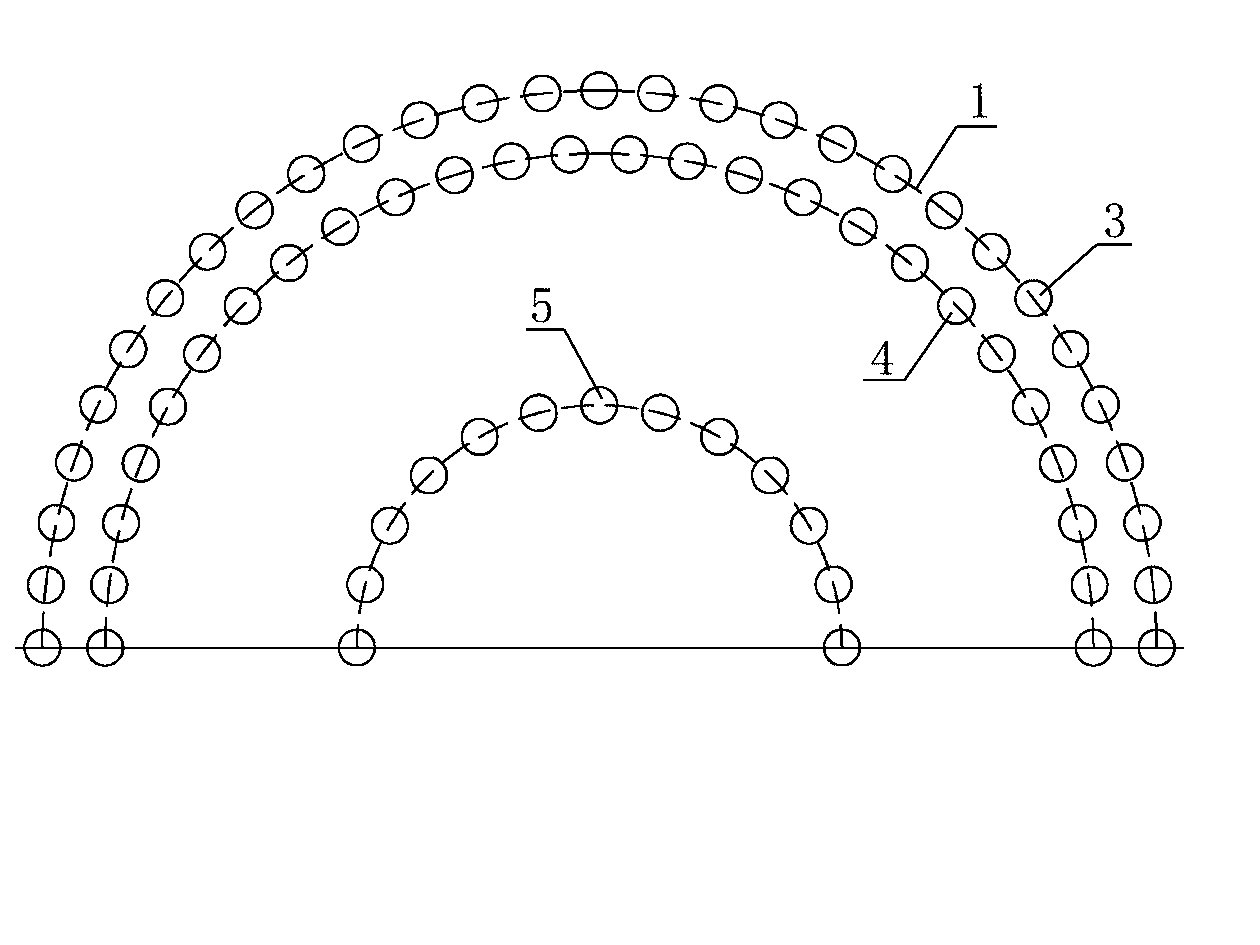

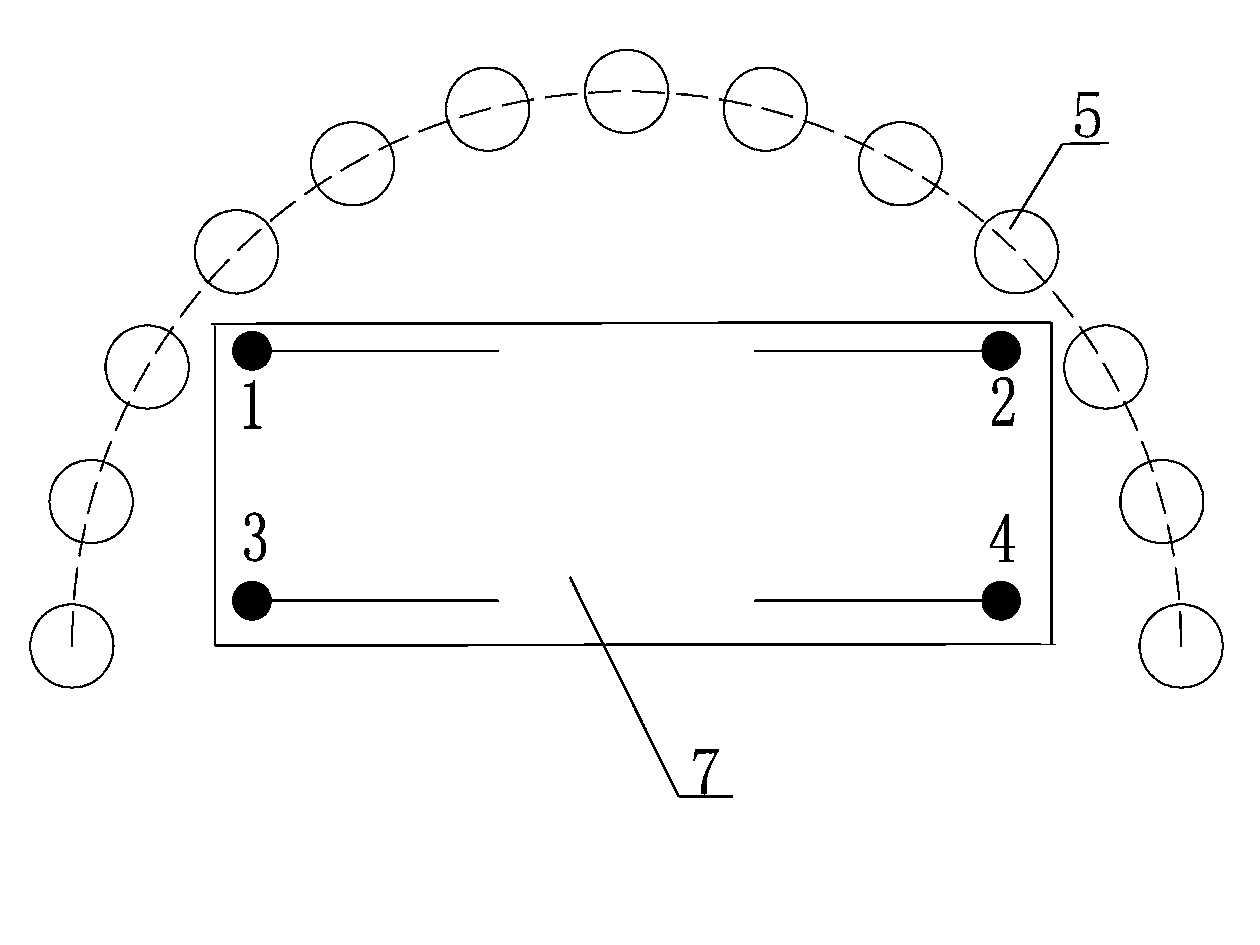

[0031] Examples see Figure 1 to Figure 4 As shown, among them, figure 2 In the middle, the solid round holes in the peripheral eye area, auxiliary eye area and cut eye area are the peripheral eye, auxiliary eye and cut hole in turn. The number indicates the rank of the detonator outside the hole.

[0032] A construction method for controlled blasting of damping holes in a tunnel, the steps of which are as follows:

[0033] Step 1, arranging the first row of damping holes 3 along the center line of the excavation contour line 1 on the face of the upper step;

[0034] Step 2, setting the second row of shock-absorbing holes 4 inwardly from the center line of the first row of shock-absorbing holes 3; Step 3, setting the third row of shock-absorbing holes 5 on the periphery of the cut eye area 7;

[0035] Step 4, arranging peripheral eyes in the peripheral eye area 2, the peripheral eyes are arranged at intervals with the first row of shock-absorbing holes 3, cutting holes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com