A wall-mounted surrounding rock section blasting excavation method for tunnels in karst areas

A wall-mounted, surrounding rock technology, used in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of cave collapse, tunnel outline over-excavation, etc., and achieve the effect of weakening energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to more clearly introduce the technical solutions involved in the present invention, further description will be given below in conjunction with the accompanying drawings.

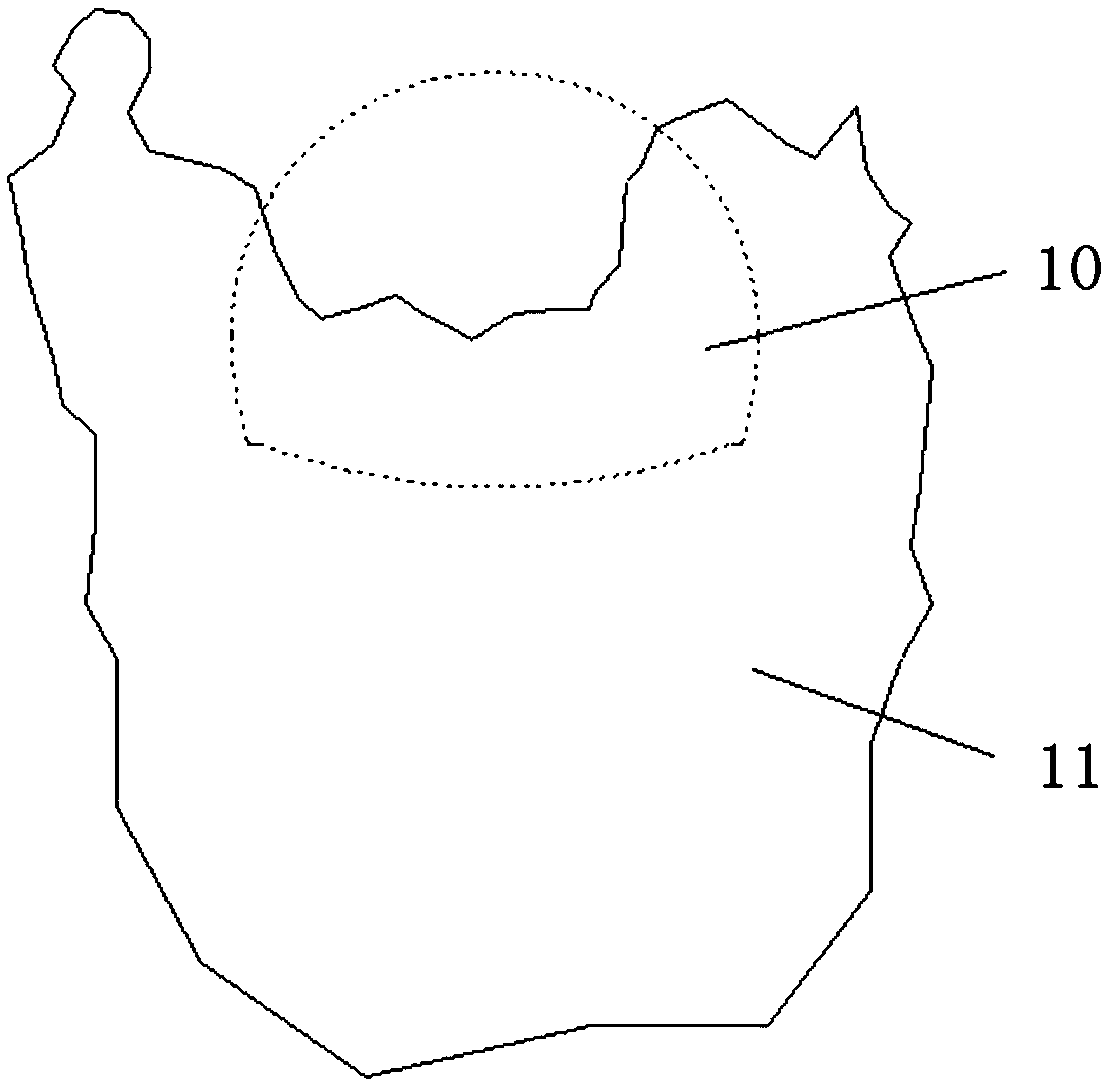

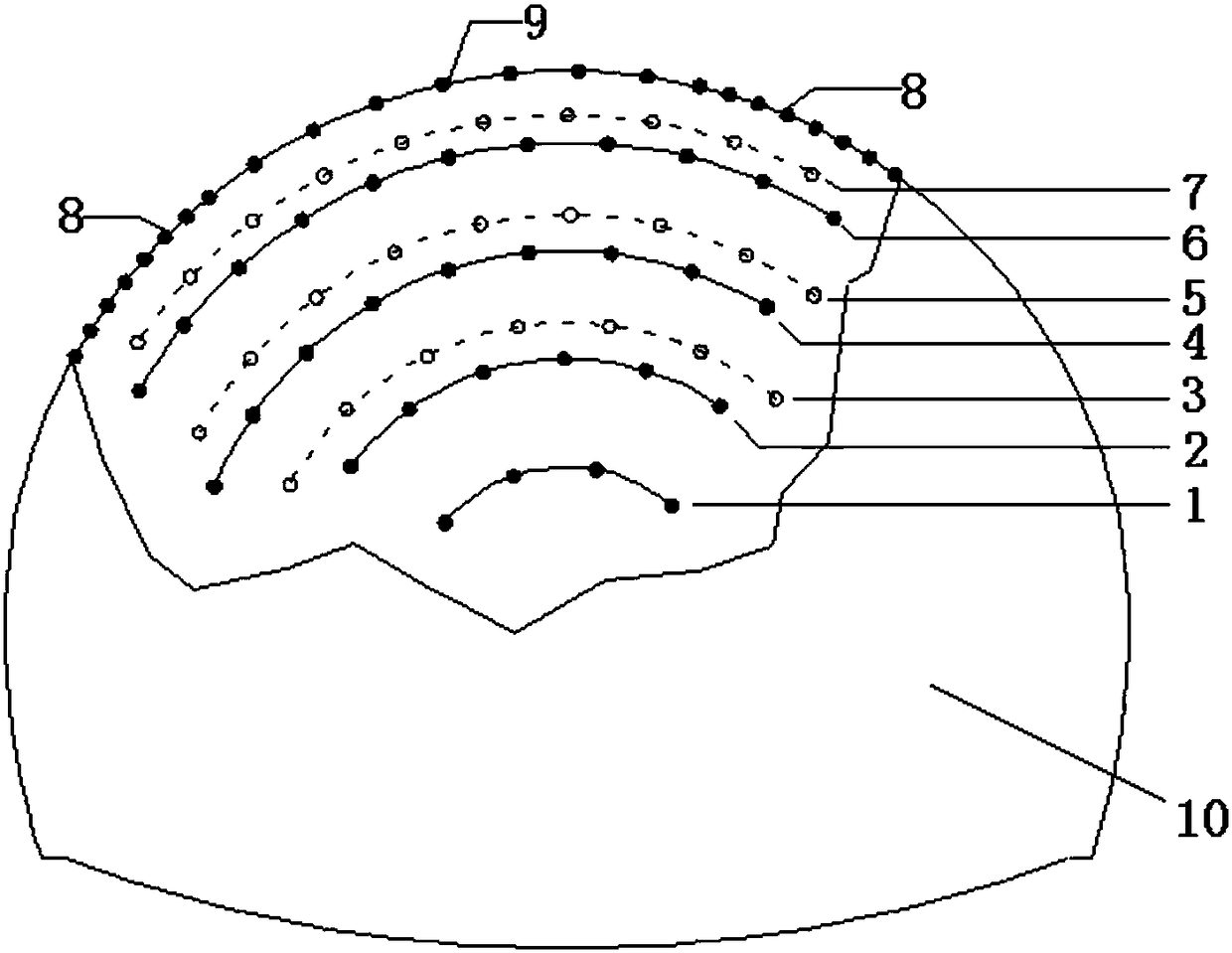

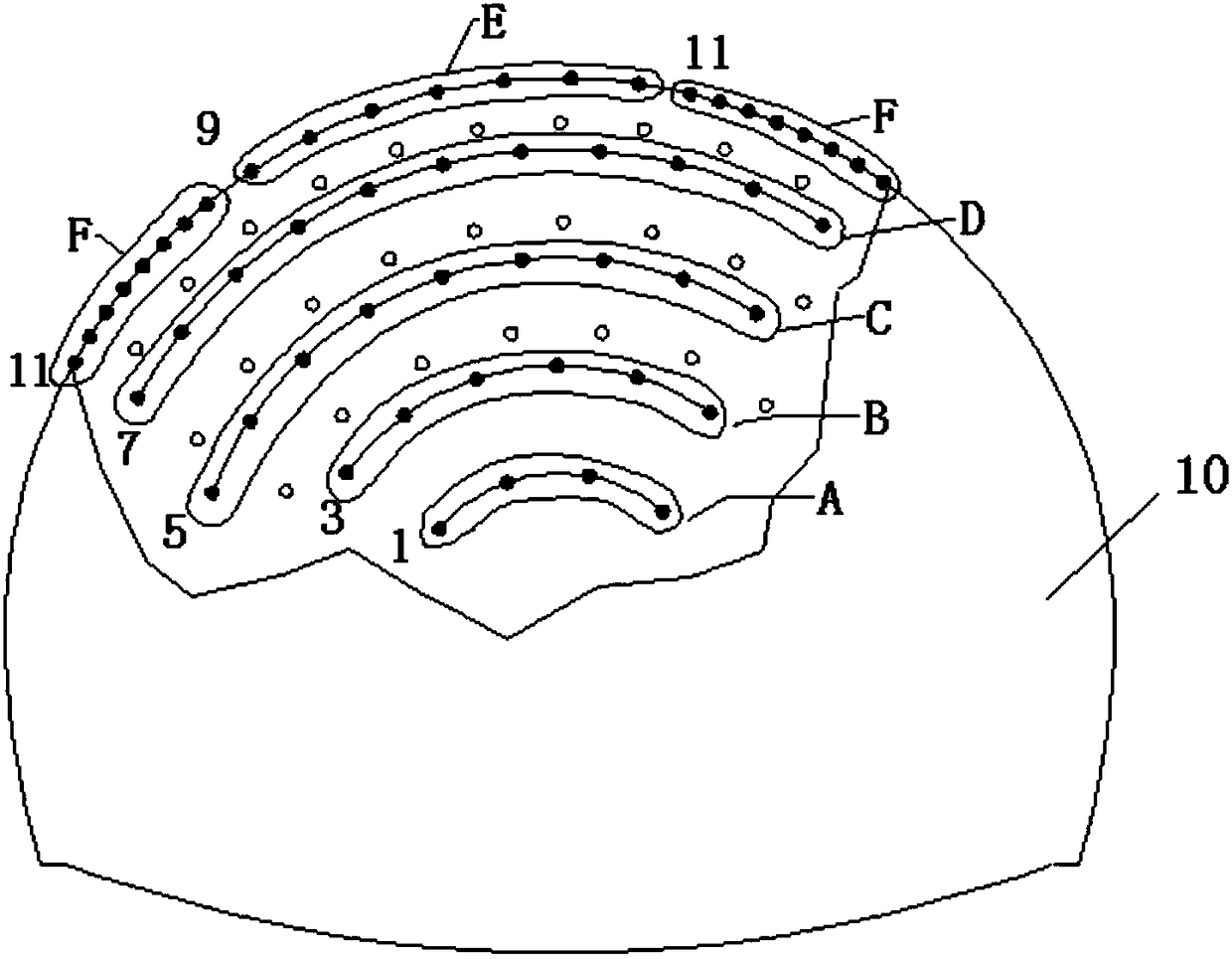

[0032] The schematic diagram of this embodiment is shown in Figure 1 to Figure 3 , figure 1 Among them, 10 is the empty area of karst cave, and 11 is the backfilling of the empty area. The intersection of the tunnel outline and the karst empty area is easily disturbed by blasting construction, and there are potential safety hazards; figure 2 In the middle, the empty eye represents the shock-reducing eye, and the solid eye is the auxiliary eye and the peripheral eye in turn; image 3 , the number marked on the edge of the hole is the corresponding segment of the blasting detonator. This embodiment is only illustrative, not intended to limit the scope of the present invention.

[0033] see figure 1 , figure 2 , image 3 and Figure 4 , the blasting excavation method of the wall-mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com