Sampling device and sampling method for measuring initial visbreaking moisture content of cutter head interface

A sampling device and water content technology, which are applied in the field of viscosity reduction design and anti-sticking of metal parts surface, can solve the problems of soil disturbance damage, unevenness, and the inability of thin layer soil to keep the shape, so as to reduce disturbance damage and improve accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the accompanying drawings and embodiments.

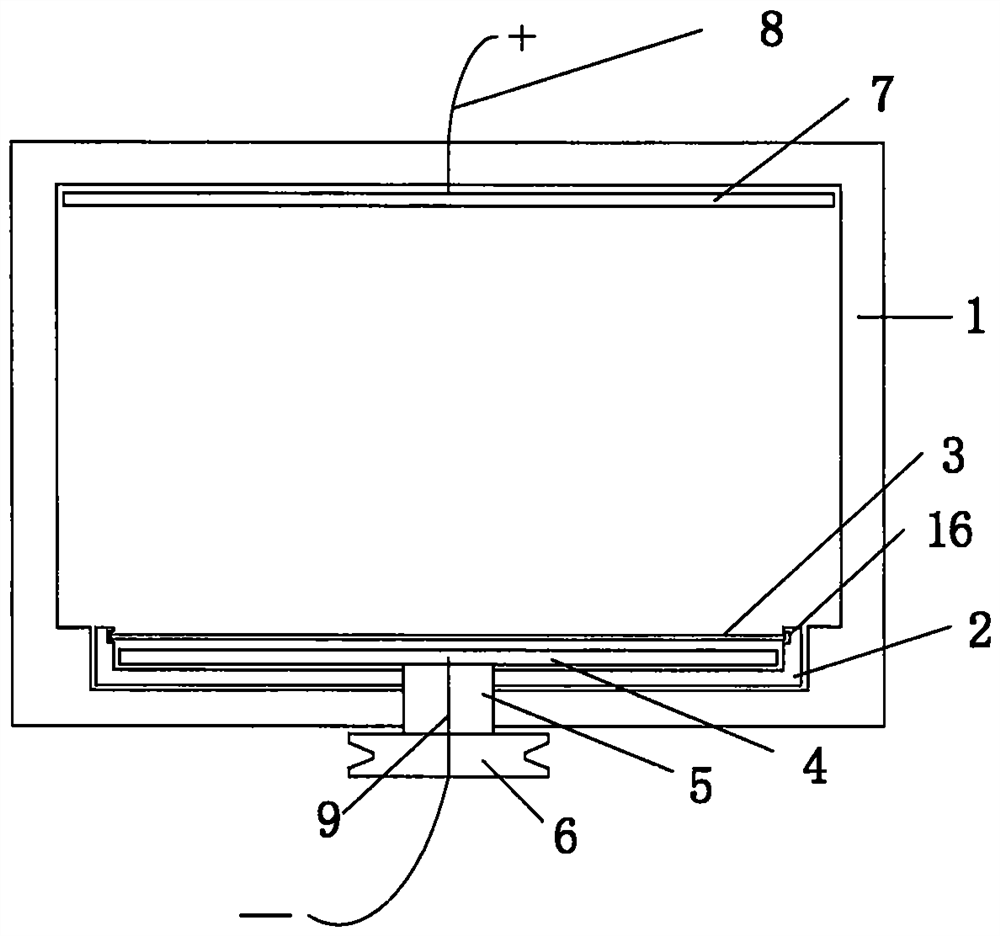

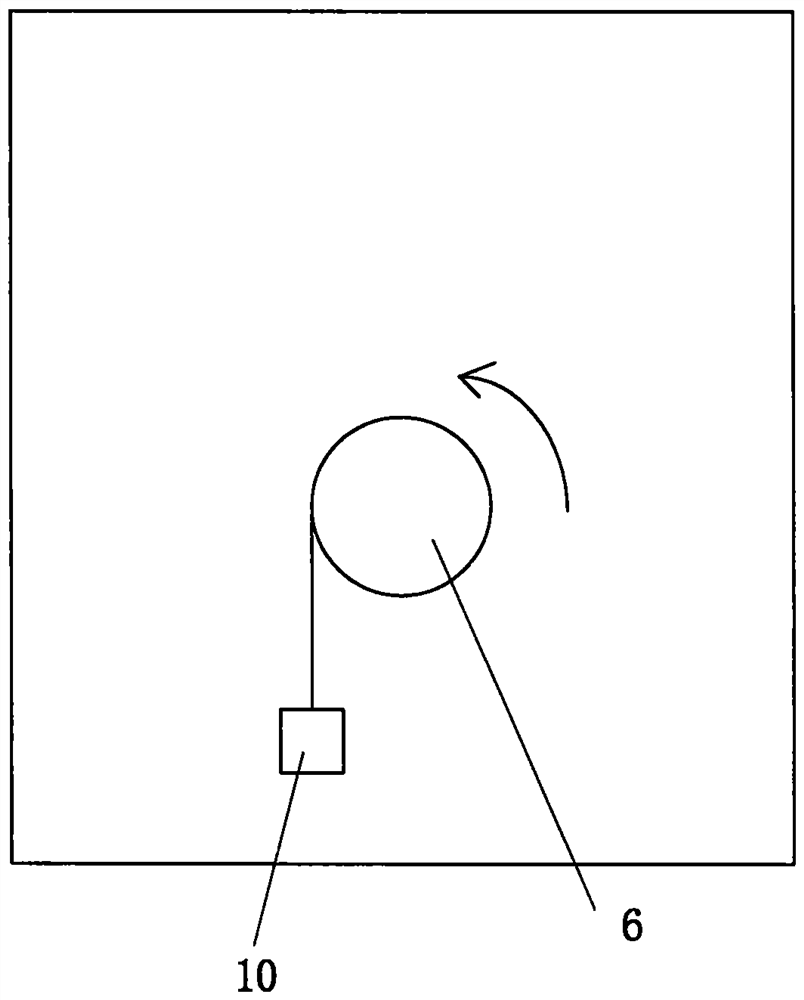

[0040] like Figure 1-Figure 3 As shown, the sampling device for measuring the initial viscosity reduction moisture content of the cutter head interface includes soil box 1, groove box 2, cutter 3, rotary cutter disc 4, rotating shaft 5, roller 6, metal plate 7, wire A 8 , wire B 9, weight 10 and pressure rod 14;

[0041] The soil box 1 and the groove box 2 are made of electrically insulating hard plastic materials;

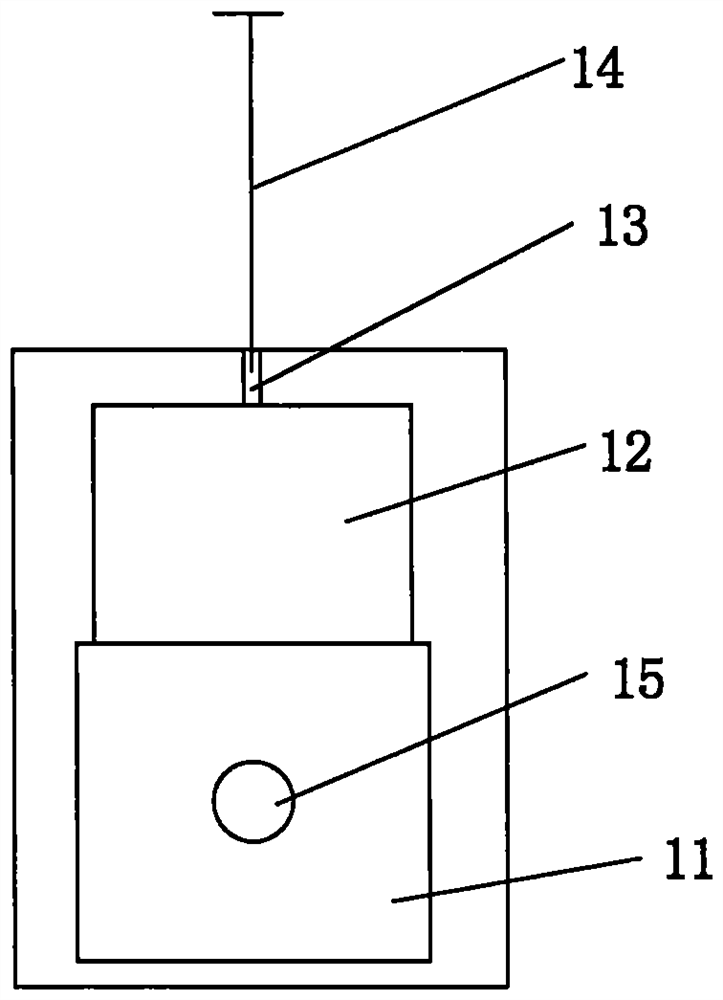

[0042] The inner side of one side of the soil box 1 is provided with groove A 11, groove B 12, tunnel 13, pressure rod 14 and hole 15; the groove A 11 is allowed to be loaded into the groove box 2; the hole 15 allows the shaft 5 to pass through; The hole 13 allows the pressing rod 14 to pass through, and the cutter 3 can be cut downward from the position of the groove B 12 and pressed into the groove C 16 of the groove box 2;

[0043] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com