Hard stone drift composite reinforcing vertical wedge cutting method

A technology of wedge-shaped cutting and rock entry, which is applied in blasting and other directions, can solve the problems of urgent optimization research, low blast hole utilization rate, and high consumption of explosive detonators, so as to improve blast hole utilization rate, increase single-cycle footage, and good blasting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

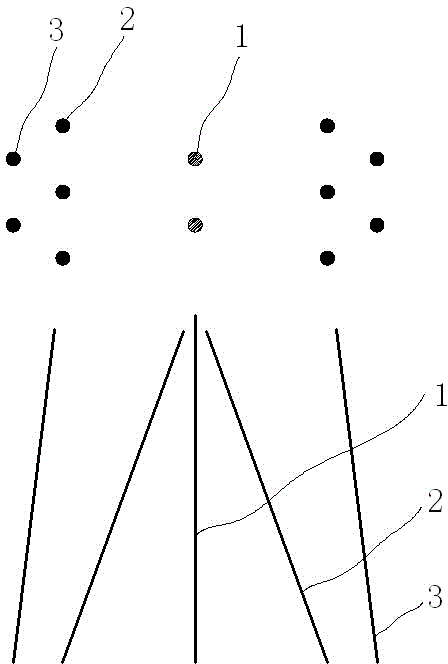

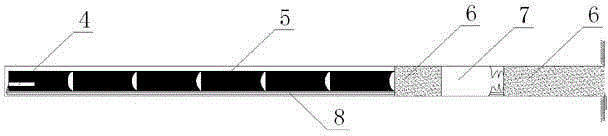

[0014] In the excavation working face of the transport roadway that adopts hydraulic jumbo rock drilling, two center holes 1 are vertically arranged at a distance of 800 mm to 1200 mm from the bottom plate at the midpoint of the centerline groove cavity of the roadway, and three pairs of main cuts are symmetrically arranged on both sides of the center hole 1 Eye 2 and two pairs of auxiliary cutting eyes 3 form a composite reinforced vertical wedge-shaped cutting. The center eye 1 has a hole spacing of 400mm and a hole depth of 2.1m to 2.2m. The main cutting eyes 2 are adjacent to each other. The vertical hole distance between the two eyelets is 400mm, the eyehole depth is 2.13m~2.23m, the horizontal angle is 70°, the distance between the 2 holes of each pair of main cutout holes is 1660m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com