Energy gathering groove cutting device used for blast hole

A cutting device and blast hole technology, which is applied to stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of poor slope forming effect and difficult blasting gas cutting blast holes, so as to save explosives and improve pre-splitting blasting Effect and blasting construction quality, operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

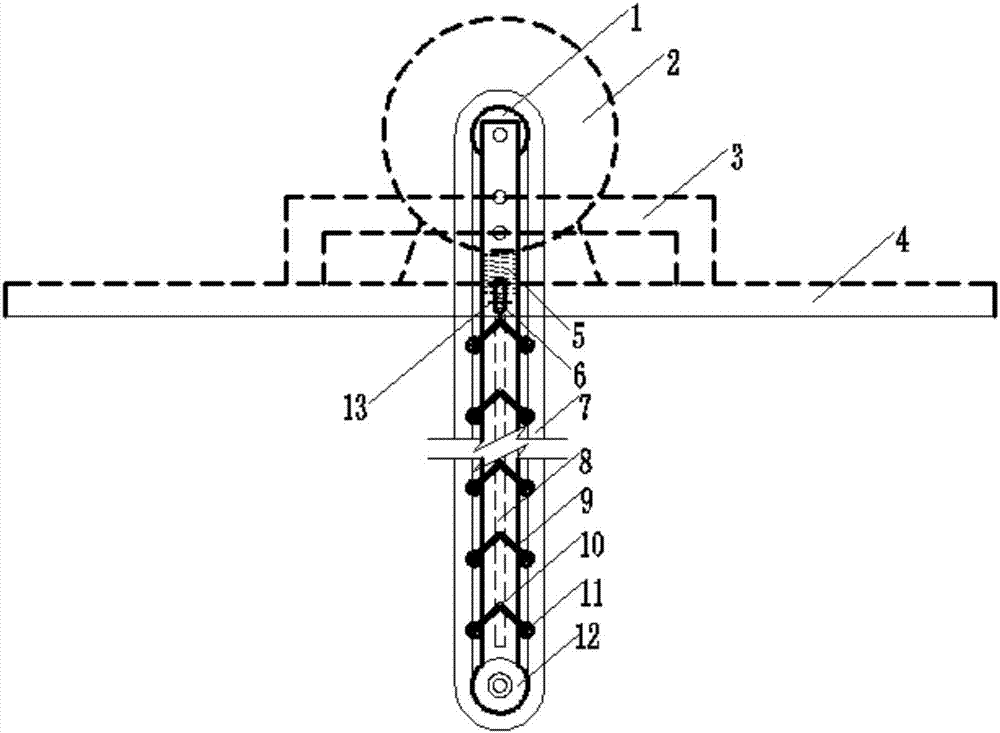

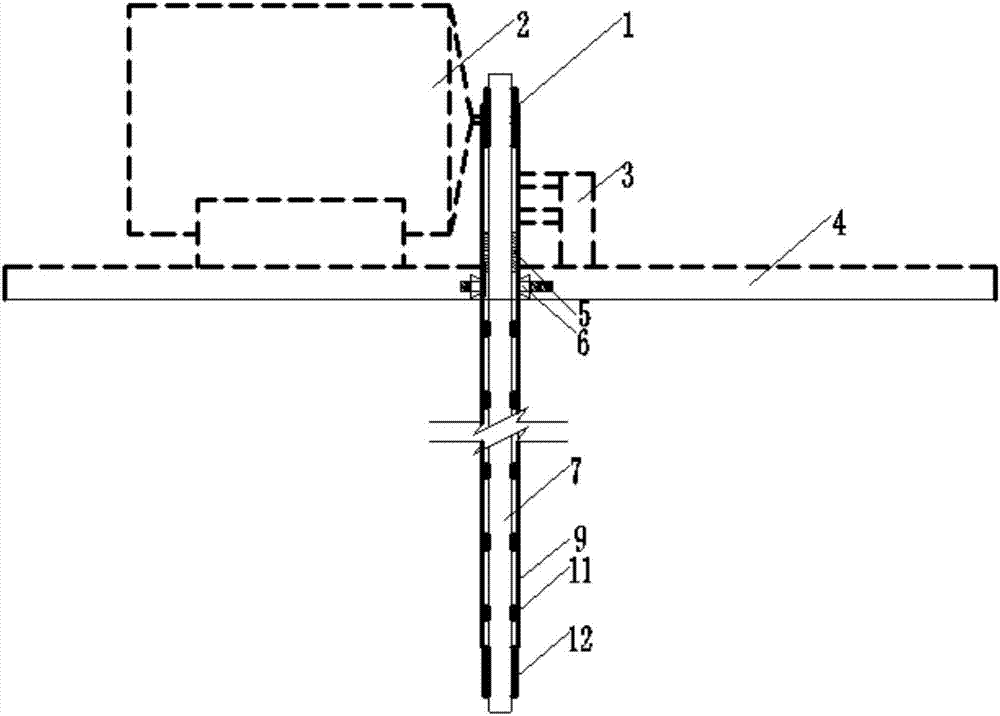

[0018] An energy collecting groove cutting device for blasting holes of the present invention comprises a motor 2, a first fixed pulley 1 and a second fixed pulley 12; the motor 2 is connected to the first fixed pulley 1, the first fixed pulley 1 and the second fixed pulley 12. A casing 9 is fixed between the two fixed pulleys 12 ; a wire saw 7 driven by the first fixed pulley 1 is arranged outside the casing 9 and between the first fixed pulley 1 and the second fixed pulley 12 .

[0019] In order to further improve the cutting effect, a sliding hole 13 is opened on the upper part of the sleeve 9, and an inner support rod 8 is arranged inside the sleeve 9; the upper end of the inner support rod 8 is connected with a fixing bolt 6 that can move up and down in the sliding hole 13; A reverse stress spring 5 for squeezing the inner support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com