Well type medium-length hole perforation segmented blasting method

A technology of segmental blasting and deep hole, which is applied in the field of well-type medium-deep hole segmental forming and perforation, charge structure and blasting, and well-type medium-deep hole perforation segmental blasting field, which can solve the problems of overhanging, squeezing, etc. The problems of large perforation deviation and upward perforation can achieve the effect of good blasting effect and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention can be explained in more detail by the following examples, and the present invention is not limited to the following examples;

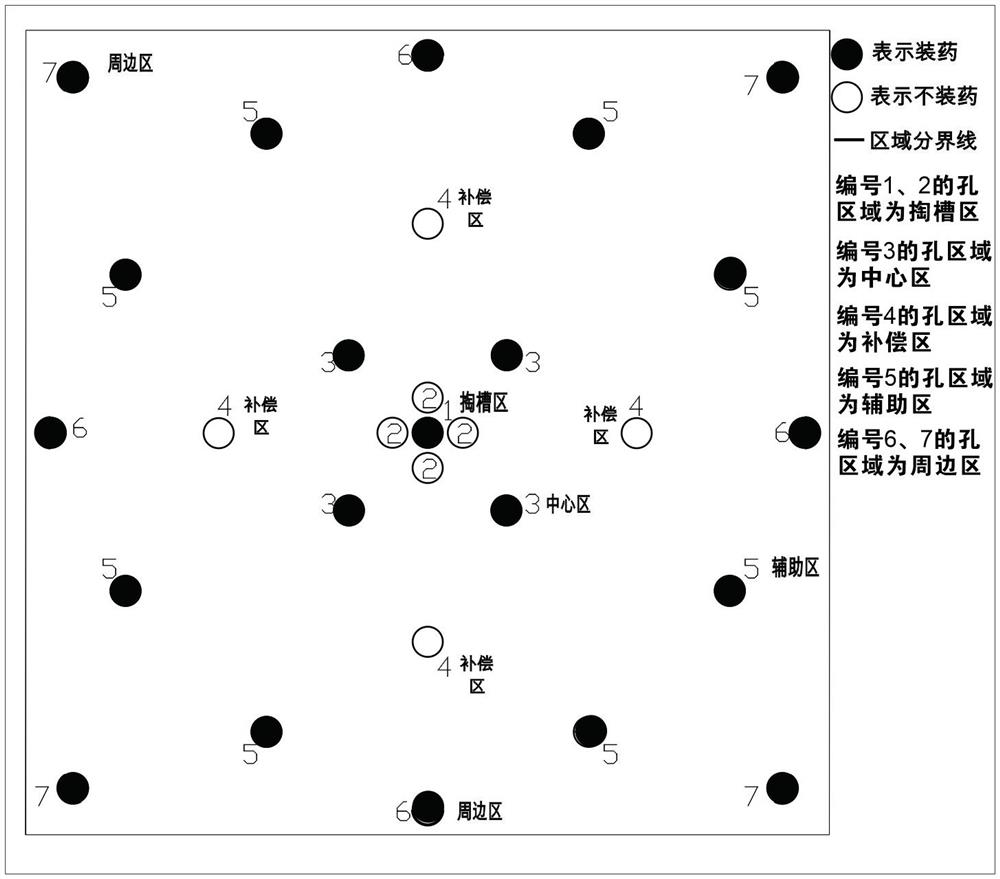

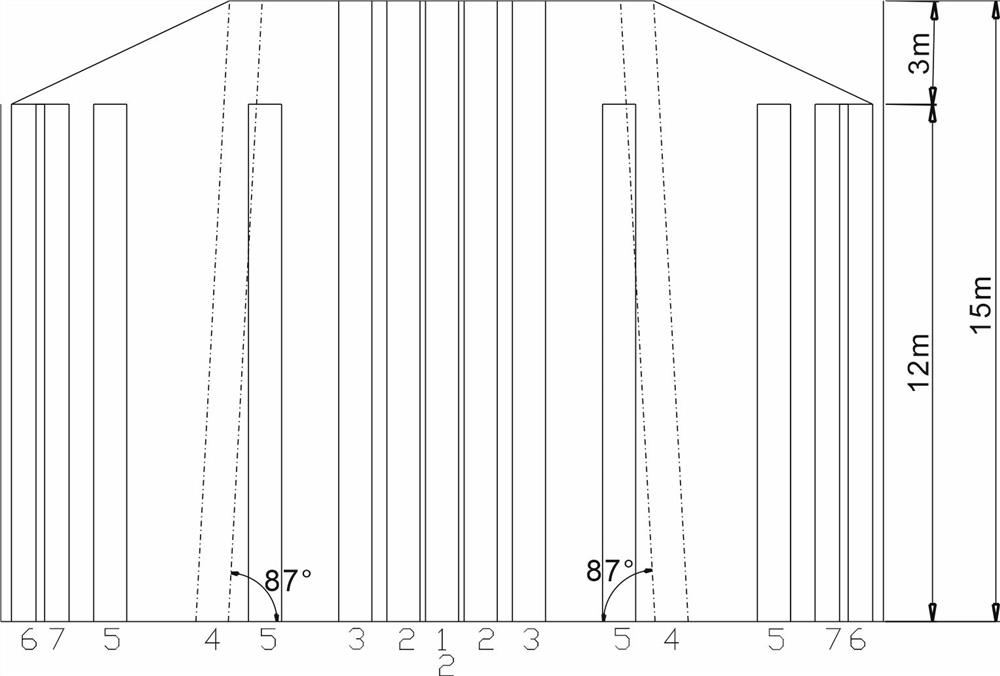

[0029] The scope of application of the present invention is in the interval of vertical depth 9m~15m, wherein one end is the spatial position situation of single head, and the present invention arranges a plurality of oblique holes outside the cutting area, such as figure 2 As shown, the layout of a plurality of inclined holes presents a trapezoidal shape from the side section. There are two effects of increasing the inclined holes. One is to increase the blasting compensation at the bottom during the same blasting process as the top of the inclined holes and the cutting area. The second is that the space state after blasting is umbrella-shaped. When blasting other holes, in addition to increasing the blasting compensation space, it also provides the effect of blasting energy gathering. Further, the present invention arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com