Tunnel medium-length hole smooth blasting method

A technology of smooth blasting and roadway, applied in blasting and other directions, can solve the problems of many holes, difficult to obtain medium and deep hole blasting effect, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

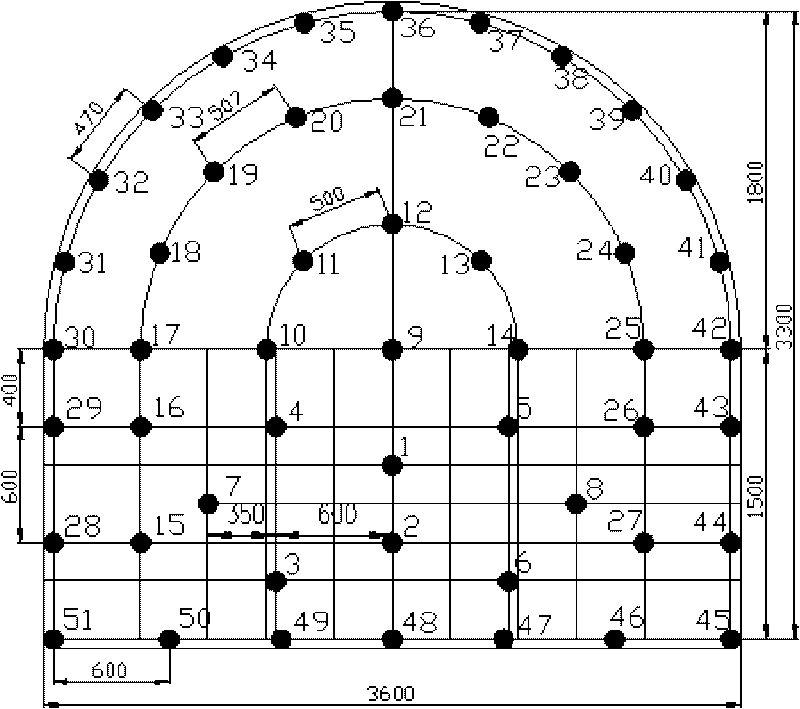

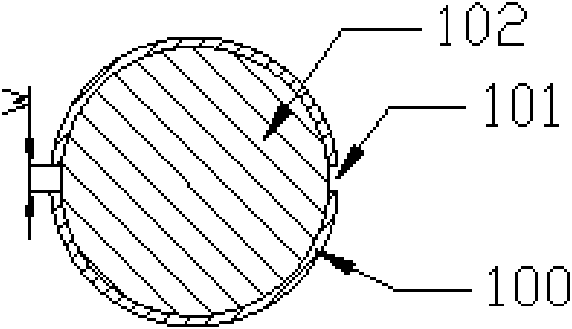

[0026] The excavation section is 10.49m 2 (3.6m×3.3m), the rock mass structure is fragmented and fragmented massive rock roadway, the method of implementing medium and deep hole smooth surface blasting is as follows.

[0027] (1) The technological process of implementing medium-deep hole smooth surface blasting on the full section is: preparation-pointing-drilling-drilling-blast hole-charging (simultaneous cutting)-connection-blasting-ventilation-slag removal-bolt / hanging net- Circulation - Shotcrete. Among them, part of the operation time can be paralleled for eyedropping and perforating, and the charging and slitting can be operated in parallel.

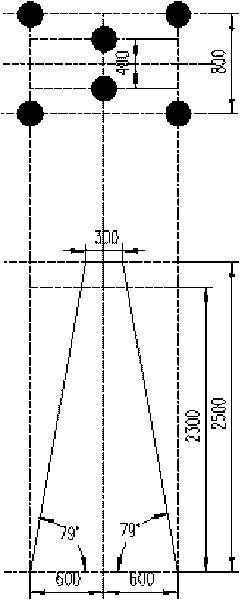

[0028] (2) see figure 1 , 2 , using "combined cutting blasting technology" to achieve medium and deep hole blasting.

[0029] ① The cutting form is the "combined cutting" method in which straight eyes and oblique eyes are combined. The number of cut holes is 6, which are holes 1 to 6, and holes 1 to 6 form a cut hole group. E...

Embodiment 2

[0047] The excavation section is 13.08m 2 (4.2m×3.5m), the rock mass structure is still fragmented and fragmented massive rock mass structure, adopt the following method to carry out medium and deep hole smooth surface blasting.

[0048] (1) The technical process and the machines and tools, equipment and safety technical measures adopted are the same as those in Embodiment 1.

[0049] (2) This embodiment also adopts "combined cutting blasting technology" and "convenient energy-directed smooth blasting technology" to achieve smooth blasting effects in medium and deep holes. The difference is that the method and parameters of "combined cutting blasting" and the parameters of "portable energy directional smooth blasting technology" have been slightly changed to meet the requirements of medium-deep hole smooth blasting after the section is enlarged. Its main points are:

[0050] ① "Combined cutting blasting technology" under the condition of enlarged section.

[0051] see Fig...

Embodiment 3

[0067] For the excavation section is 13.08m 2 (4.2m×3.5m), when the roadway is in a rock mass structure that is difficult to blast, adopt the following method to achieve the smooth blasting effect of medium and deep holes.

[0068] (1) The technological process and the implements, equipment and safety technical measures adopted in the present embodiment are the same as in the second embodiment.

[0069] (2) This embodiment also adopts the "portable energy-directed smooth surface blasting technology" to achieve the smooth surface blasting effect, and the surrounding ophthalmic rolls are "cut" in the same manner as in Embodiment 1. The difference is that this embodiment adopts the enhanced "double-slant eye combined cutting blasting technology" to enhance the cutting effect and realize the blasting effect of medium and deep holes. Its main points are:

[0070] ①Double squint combined cutting blasting technology. see Figure 7 , Figure 8 .

[0071] The cutout eye group con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com