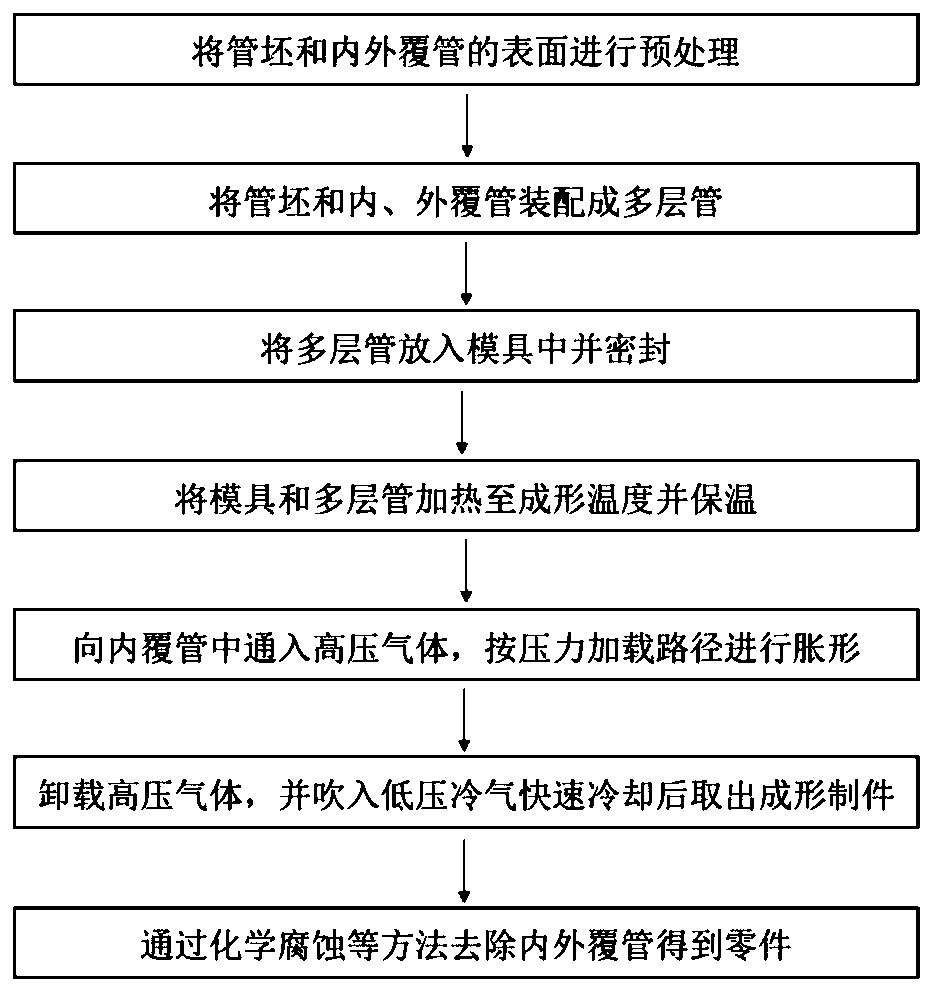

Multi-layer tube assisted rapid inflation device and method for curved pipe fittings made of dissimilar materials

A technology of dissimilar materials and multi-layer tubes, applied in the processing of rods or profiles, metal plates or tubes, can solve problems such as uncoordinated deformation, rough welds, residual stress, etc., to avoid uncoordinated deformation and reduce overall quality , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

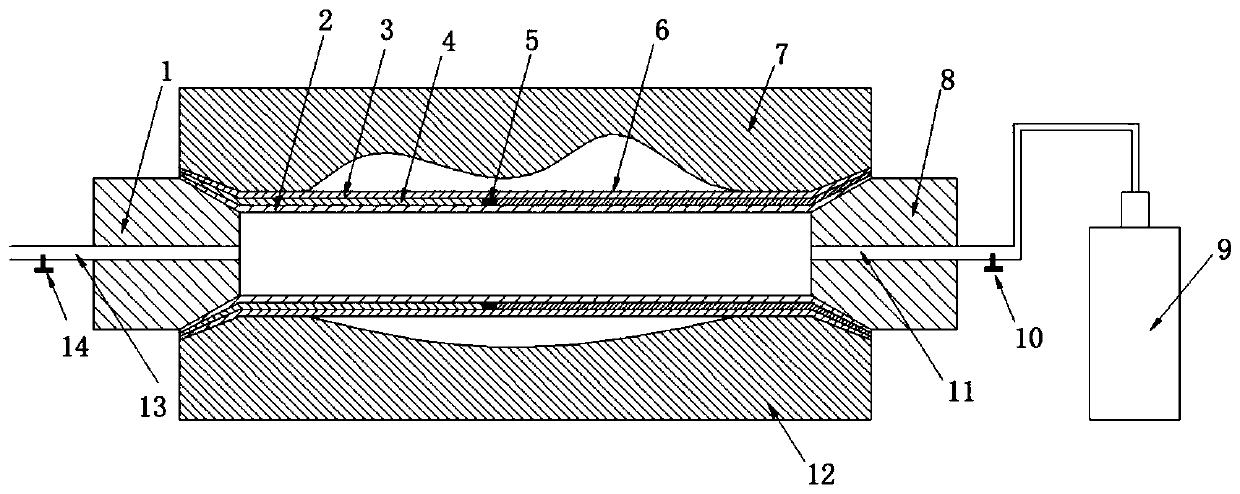

[0038] Such as image 3 as shown, image 3 It is a front cross-sectional view of the multi-layer tube assisted rapid inflation device for curved pipe fittings made of dissimilar materials in this embodiment. Pipe 3, cylinder 9, intake valve 10, intake pipe 11, outlet pipe 13 and pressure relief valve 14. The cavity surface of the upper mold 7 and the cavity surface of the lower mold 12 are sequentially provided with an outer covering tube 3 , a tube blank 4 and an inner covering tube 2 in the direction of the central axis of the device. The left push head 1 and the right push head 8 are respectively inserted into the left and right sides of the inner covering pipe 2 and moved axially to the multilayer pipe 6 to ensure sealing; There is an air outlet pipe 13 and an air inlet pipe 10 communicating with the inner cavity of the inner covering pipe 2, the air outlet pipe 13 communicates with the external environment, and is controlled by a pressure relief valve 14, and the air in...

Embodiment 2

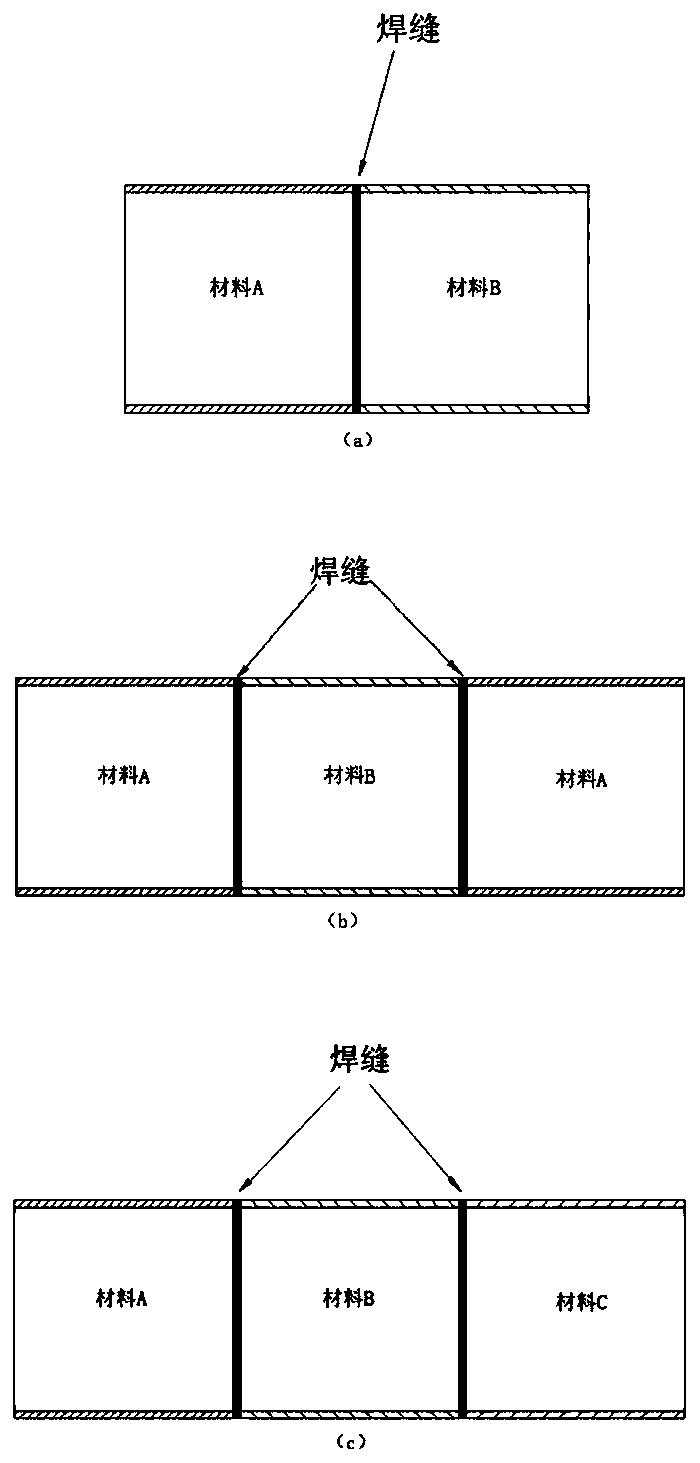

[0051] Such as Figure 5~6 As shown, using the forming device and forming method of the present invention, the specific steps are similar to the above-mentioned embodiment 1. It's just that the tube blank is welded by three different materials. Figure 5 It is the front cross-sectional view of the multi-layer tube assisted rapid inflation device of the heterogeneous material curved pipe fitting of this embodiment before forming; Image 6 It is the front cross-sectional view of the multi-layer tube assisted rapid inflation device of the heterogeneous material curved pipe fitting welded by three different materials in this embodiment after forming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com