Tabia as well as preparation method and use method thereof

A soil and mixture technology, applied in construction, construction material processing, roads, etc., can solve the problems affecting strength, flexural resistance, anti-skid and water and frost resistance, poor strength, water resistance, frost resistance, and three-component soil reaction time Slow and other problems, to achieve the effect of simple and convenient technical construction, good frost resistance performance, and short molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Another embodiment of the present invention provides a method for preparing the compound clay, comprising the following steps:

[0039] 1) Quantify the mixture, crack-resistant fiber, admixture and water;

[0040] 2) Mix the admixture with water to form an admixture dilution;

[0041] 3) Stir the mixture and anti-cracking fiber evenly, and the stirring time is more than 5 minutes;

[0042] 4) Spray the prepared admixture dilution and continue to stir for more than 5 minutes.

[0043] Preferably, the equipment for stirring the mixture and the anti-cracking fiber includes a forced stirrer, and the rotational speed of the forced stirrer is above 150 r / min.

[0044] Another embodiment of the present invention provides a method for using a composite clay, including a method for preparing the composite clay, comprising the following steps:

[0045] 1) Formulate the paving thickness after compaction;

[0046] 2) Spread the mixed material loosely on the surface to be constr...

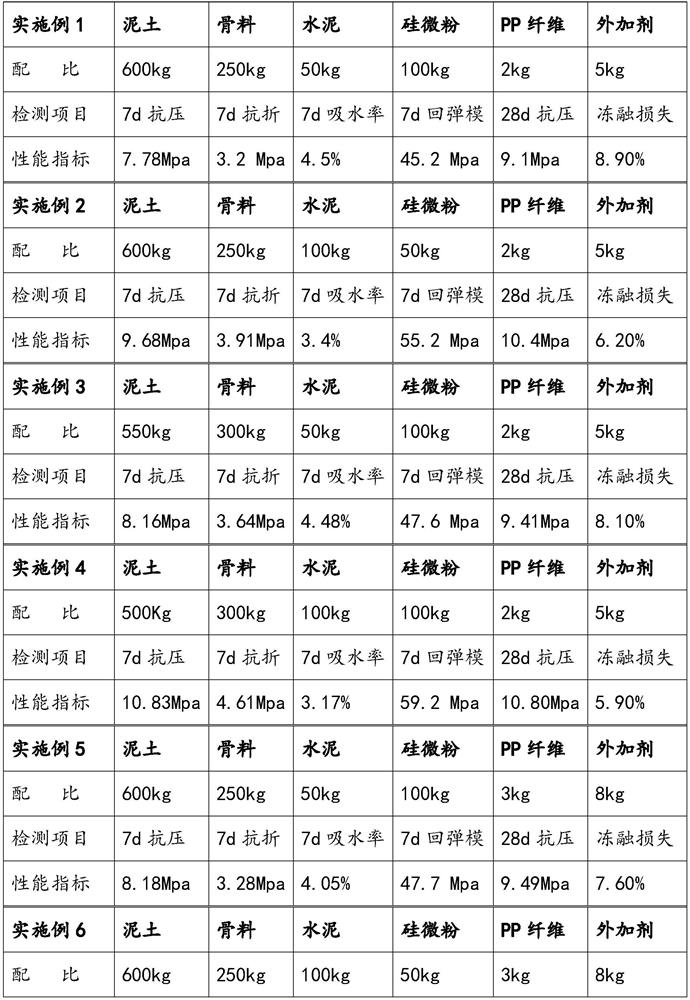

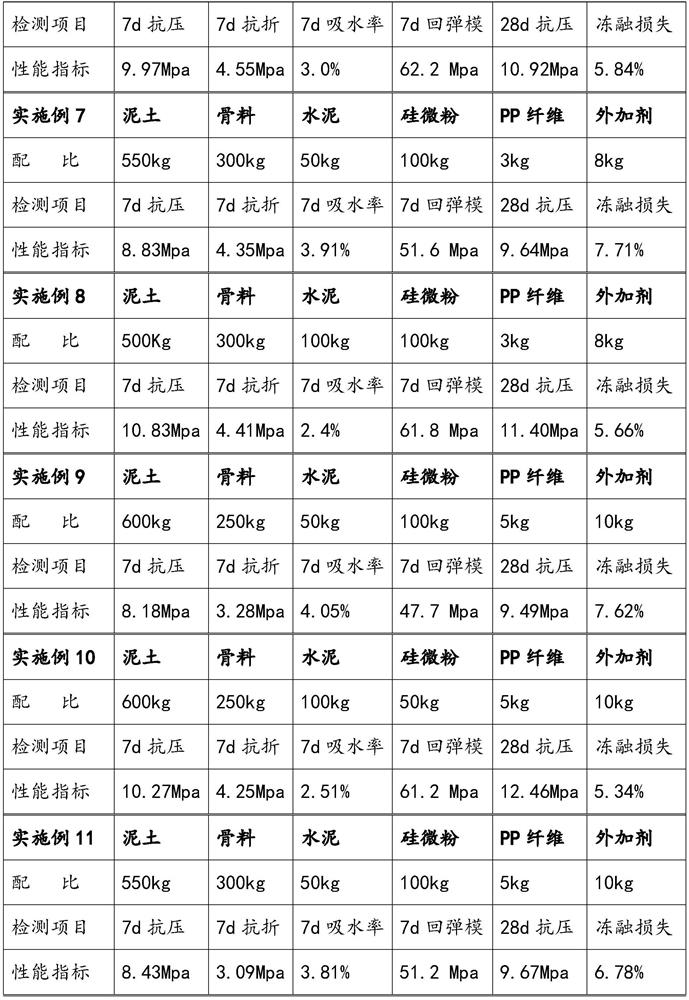

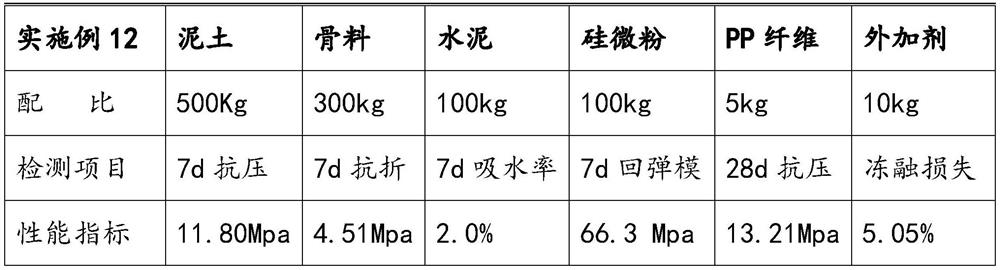

Embodiment 1

[0061] 1. Take 600kg of soil, 250kg of graded stone aggregate, 50kg of cement, and 100kg of silica powder. Take 2 kg of anti-cracking fiber which is the weight of the above mixture, and use a mixer to stir for 5 minutes.

[0062] 2. Take 5kg of admixture by the weight of the above mixture to prepare admixture dilution. According to the geotechnical test, calculate the optimum water content under the condition of maximum dry density of the mixture. After measuring the on-site water content on the day, the actual amount added is 3.1%, that is, 31kg. Adding the water consumption greater than 3%, use 61kg of water to dilute 5kg in total. The special admixture, and the admixture is evenly stirred in water for 1min to prepare a dilution.

[0063] 3. Stir the mixture. Put the mixture prepared in the first step into the mixer, firstly stir the dry material, the speed of the mixer should be greater than 150r / min, not less than 5min, and then use the admixture dilution prepared in the...

Embodiment 2

[0069] 1. Take 600kg of soil, 250kg of graded stone aggregate, 100kg of cement, and 50kg of silica powder. Take 2kg of anti-cracking fiber which is the weight of the above mixture, and use a mixer to stir for 5min

[0070] 2. Take 5kg of admixture by the weight of the above mixture to prepare admixture dilution. According to the geotechnical test, calculate the optimum water content under the condition of maximum dry density of the mixture. After measuring the on-site water content on the day, the actual amount added is 3.1%, that is, 31kg. Adding the water consumption greater than 3%, use 61kg of water to dilute 5kg in total. The special admixture, and the admixture is evenly stirred in water for 1min to prepare a dilution.

[0071] 3. Stir the mixture. Put the mixture prepared in the first step into the mixer, firstly stir the dry material, the speed of the mixer should be greater than 150r / min, not less than 5min, and then use the admixture dilution prepared in the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com