Railway fastener elastic strip forming die and forming method

A technology for railway fasteners and forming dies, which is applied in the field of mechanical processing, can solve the problems of long forming time, large cumulative error of multiple positioning, high one-time investment, etc., and achieves the effect of convenient use and operation and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described below with reference to the drawings.

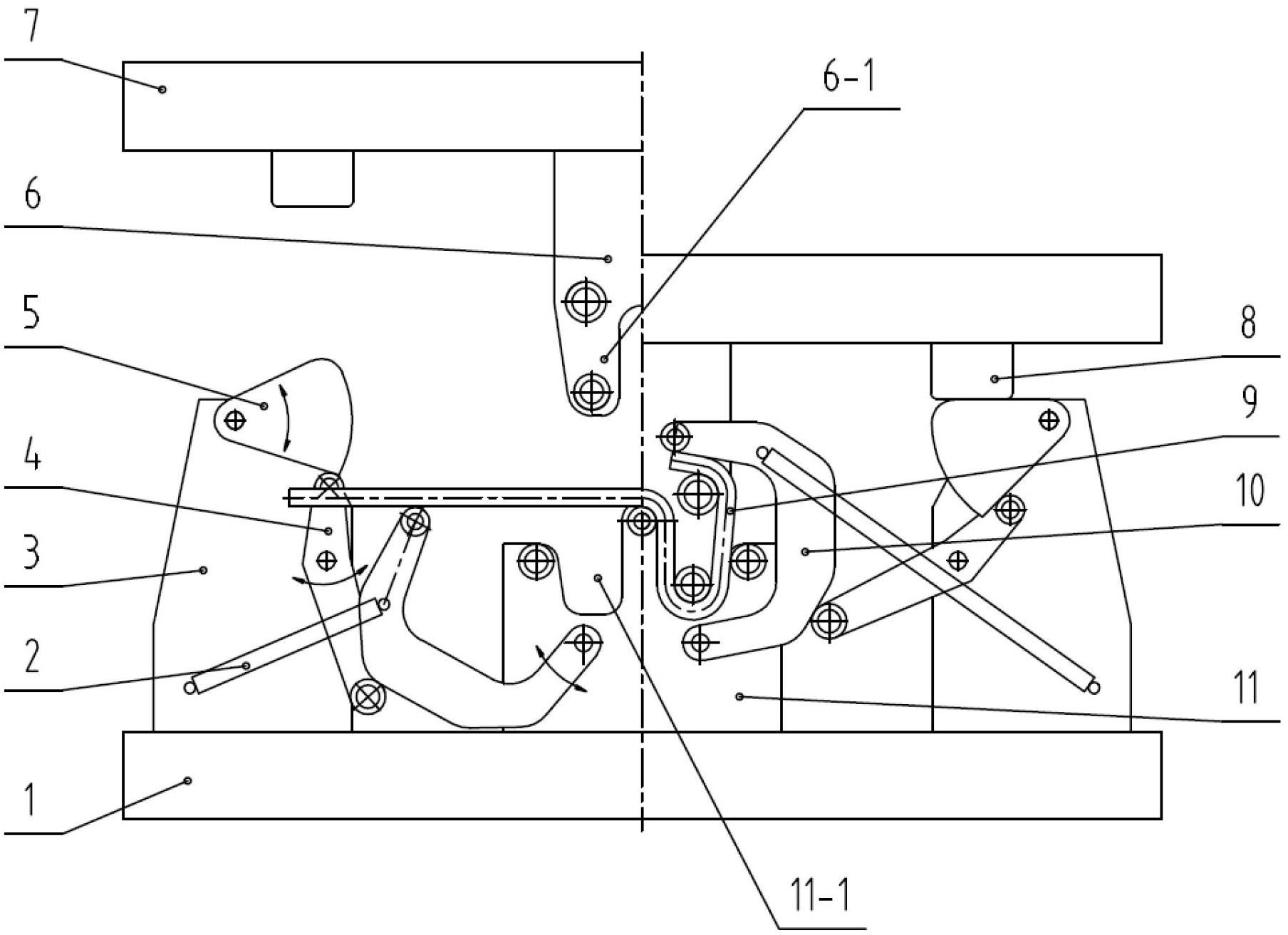

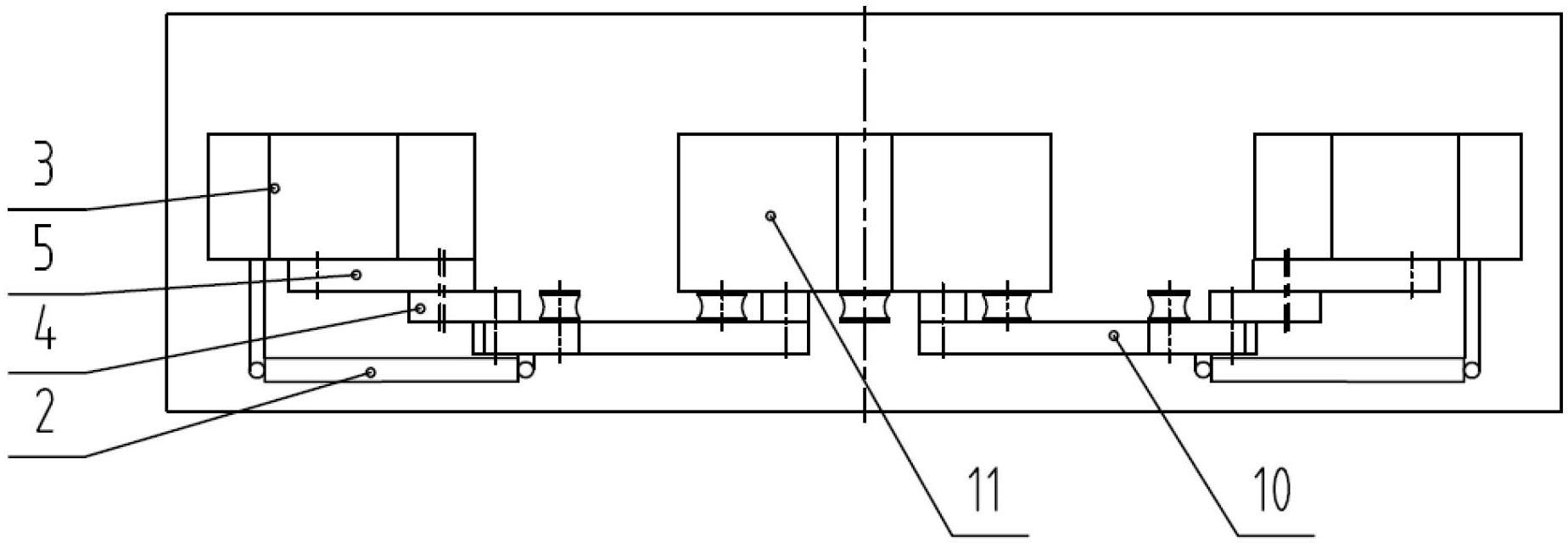

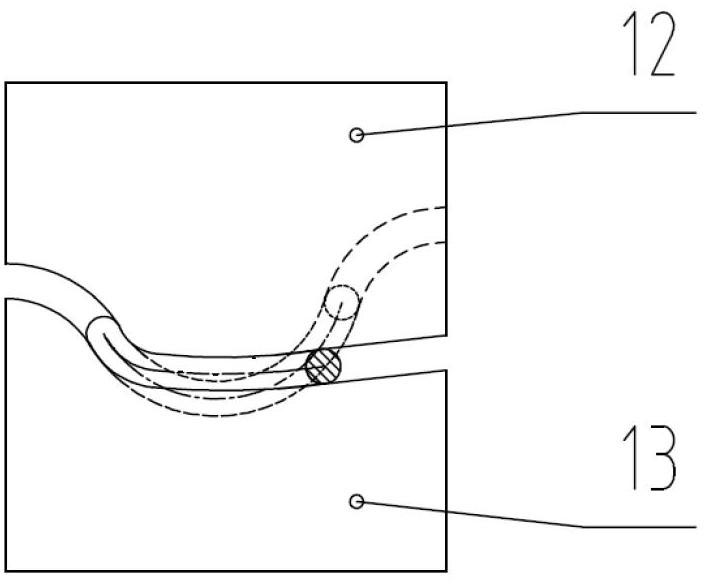

[0033] see Figure 1 to Figure 2 , the present invention provides a railway fastener clip forming mold, which is suitable for processing and forming a specific ω-shaped clip, and the railway fastener clip (such as Figure 7 shown) is obtained by inserting the elongated spring bar blank 9 (such as Figure 6 Shown) After heating, it is sent into this mold for pressing, and it is pressed into finished products through space fluctuations (such as Figure 8 , Figure 9 shown).

[0034] Specific as figure 1 and figure 2 In the first embodiment shown, the forming mold mainly includes a base 1 , a bracket 3 and an upper template 7 . The base 1 is fixed with a lower roller frame 11, which is provided with an ω-shaped groove 11-1, and the upper template 7 is provided with an upper roller frame 6 that cooperates with the lower roller frame 11, and the upper roller frame 6 The pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com