Heating type electromagnetic rivet-free connecting device and working method

A connecting device and rivetless technology, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of unsatisfactory performance of connecting joints in the forming effect, limited room for improving the performance of connecting joints, and difficulty in one-time stamping and forming, etc. Problems, achieve the effect of shortening the forming time, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

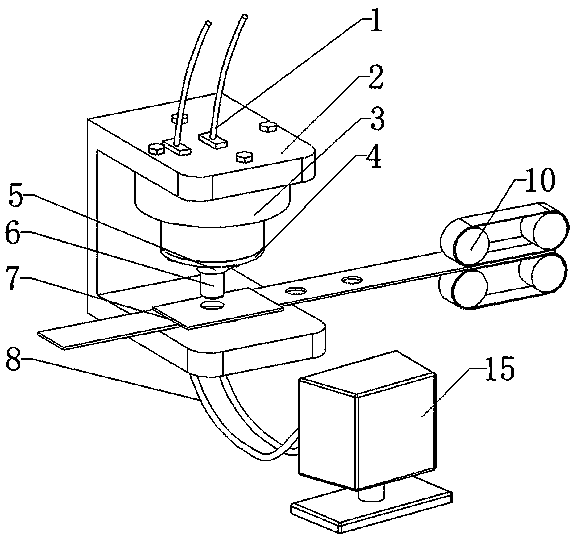

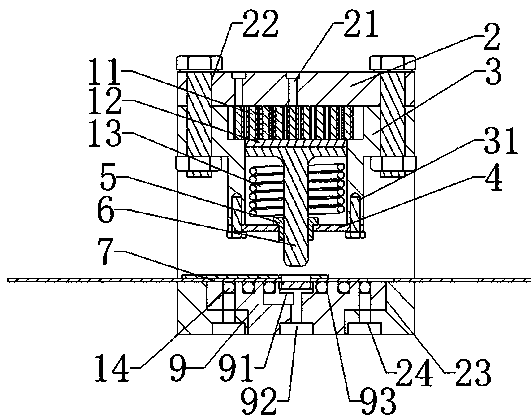

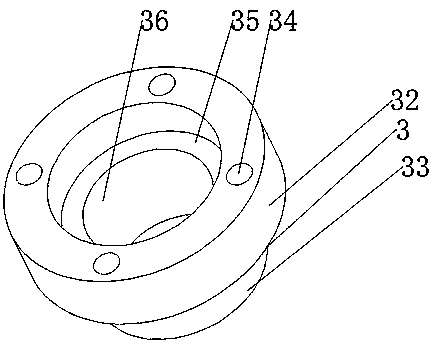

[0063] Such as Figure 1-15 As shown, a heating type electromagnetic rivetless connection device, the connection device includes a fixed frame 2; the upper part of the fixed frame is provided with a punch driving device, and the lower part is provided with a riveting die 9; the riveting die is provided with an eddy current The effect is the induction heating coil 14 for heating the workpiece to be connected; the punch driving device includes an electromagnetic induction coil 11 and a driver 12 with a metal structure connected to the punch 6; the electromagnetic induction coil is close to or connected to the metal structure of the driver , when the electromagnetic induction coil is working, the alternating magnetic field formed by its electrification induces an induced current forming a mutually repulsive magnetic field at the metal structure of the driver, and the electromagnetic induction coil pushes the driver downward with electromagnetic repulsion, driving the punch to impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com