Environmentally friendly water-based phenolic resin for speaker springs

A technology of water-based phenolic resin and phenolic resin, which is applied in the field of loudspeaker elastic wave production, to achieve the effects of low production cost, improved performance index, and fast forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The composition of an environment-friendly water-based phenolic resin used for loudspeaker elastic waves is as follows: 73.8% phenolic resin, 3.6% phenol, 1.4% m-hydroxybenzyl alcohol, 1.3% oleic acid, 18.7% water, and 1.2% sodium hydroxide.

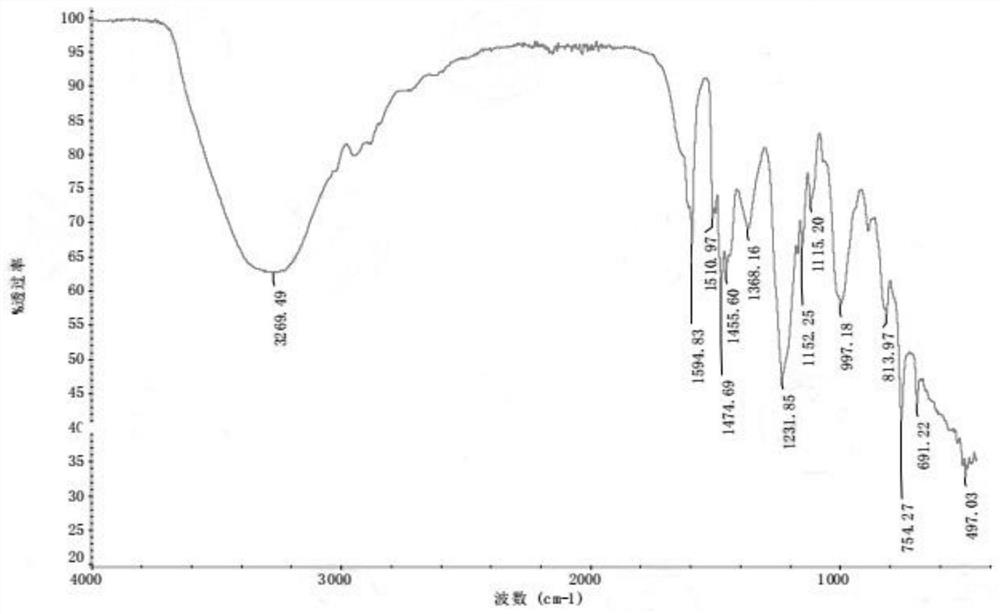

[0015] The above-mentioned water-based phenolic resin impregnation is detected by spectrometer, energy spectrometer and chromatography-mass spectrometer, and its main spectrogram is as follows: Figure 1-4 Shown; (1) FTIR spectrogram;

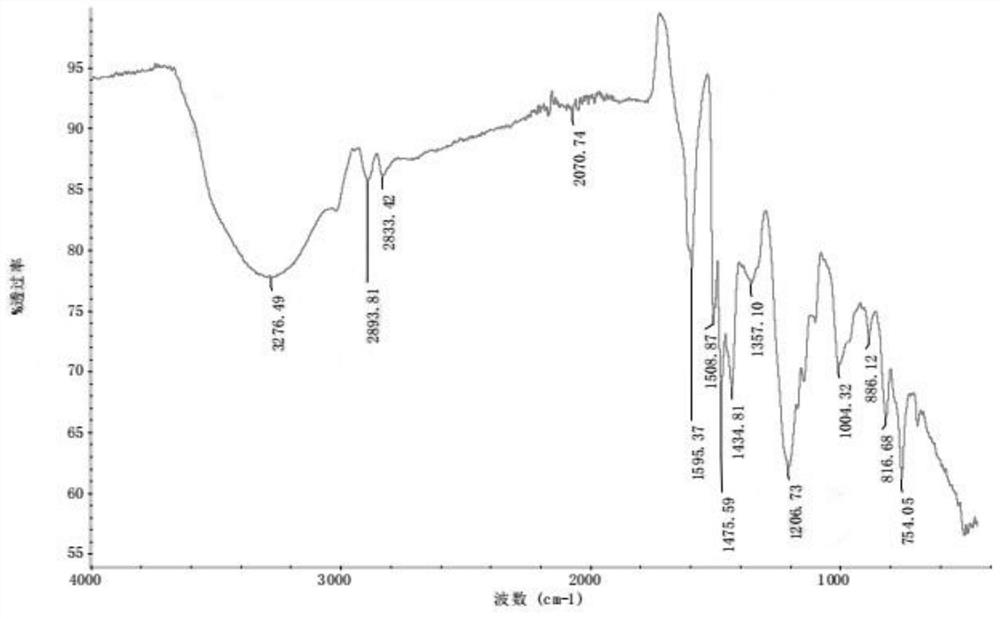

[0016] (2) FTIR representative spectrum in the separation process;

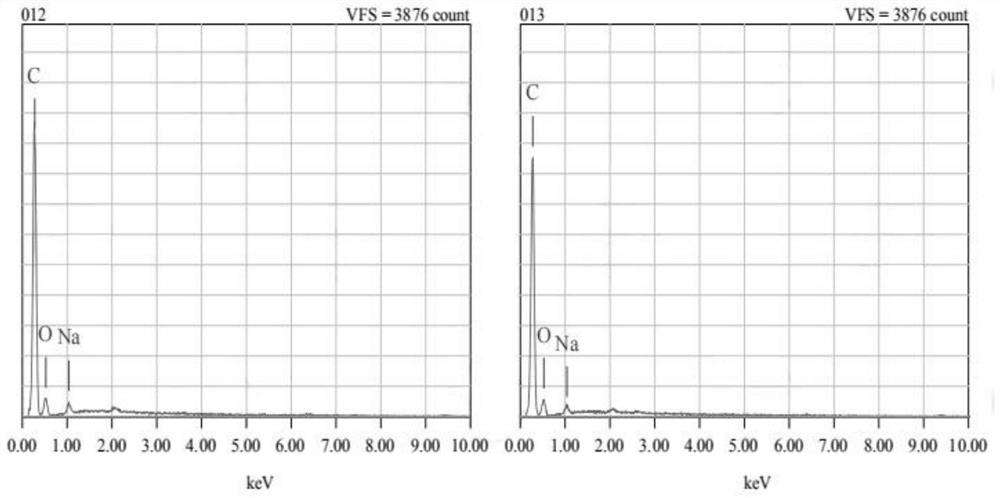

[0017] (3) Elemental analysis spectrum;

[0018] (4) GC-MS TIC diagram.

[0019] The water-based phenolic resin prepared by the above-mentioned embodiment has the advantages of high strength and good temperature resistance, and its performance index is shown in the following table:

[0020] Table 1 Resin performance index detection data

[0021]

[0022] After testing, the product of the present invention complies with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com