Full-area three-dimensional molding system

A three-dimensional forming and full-area technology, applied in the field of manufacturing system devices, can solve the problems of unable to automatically select printing forming materials, low strength of parts, and less forming materials, etc., to meet physical and chemical properties, short forming time, and forming accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

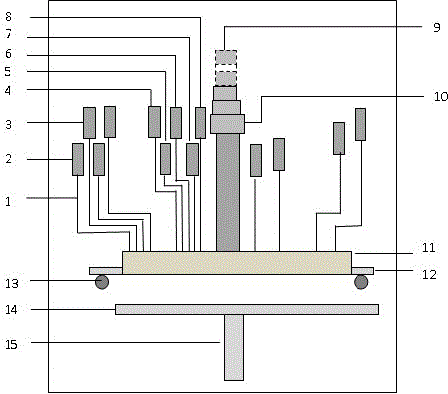

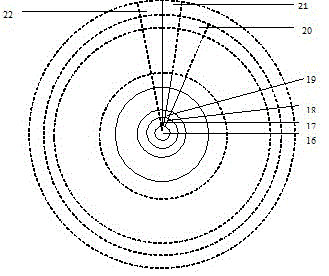

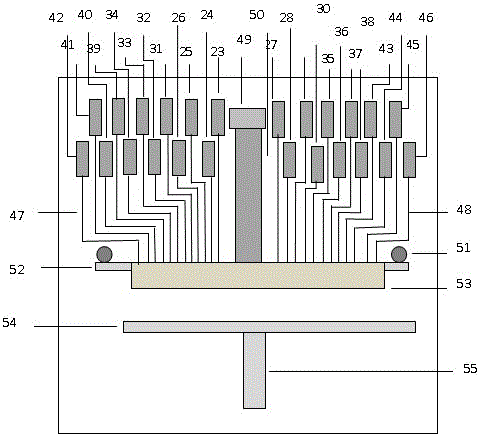

[0024] Embodiment 1, the molding system used in the embodiment of the present invention is a full-area three-dimensional molding system with eight orifice units, and its structure is as follows image 3 As indicated, the three-dimensional diagram is as Figure 4 shown. The full-area forming system with eight orifices uses three rings of print head brackets, each of which can rotate freely at 360 degrees, and eight printing orifice units are placed in each ring, a total of twenty-four printing orifice units. According to the finite element analysis of the model, the model cloud image of eight gray colors is obtained, and the eight colors are rendered on the original model, and one color is defined to correspond to one material, so that the eight printing nozzle unit pairs correspond to eight printing shapes Materials, which correspond to seven printing and forming materials, and one printing and forming support material. The eight material boxes are divided into eight colors,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com