Air pressure loading based vibration creep combined incremental age forming method and device

A progressive forming and age forming technology, which is applied in the field of curved surface forming of ribs and plates, can solve the problems of incomplete elimination of residual stress, long aging forming time, uneven distribution of internal stress, etc., and achieve complete release of residual stress, good dimensional stability, The effect of microscopic grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

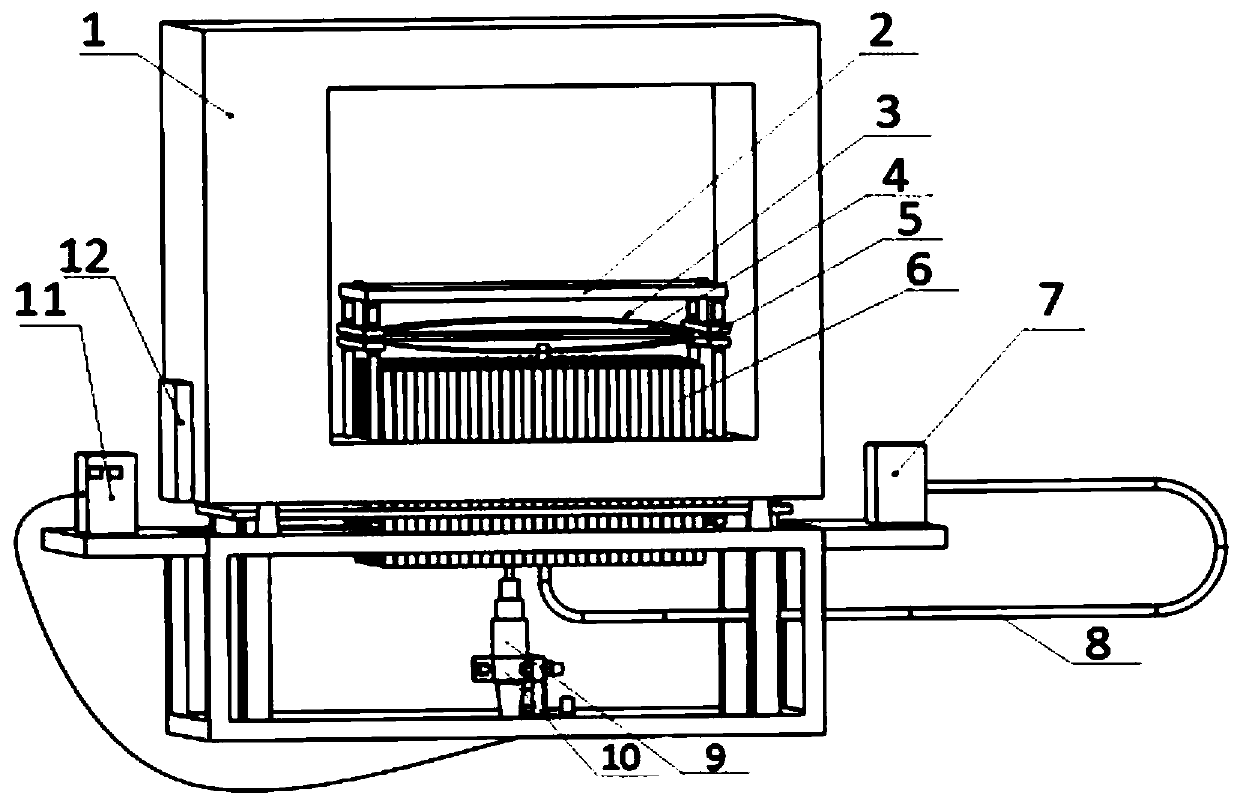

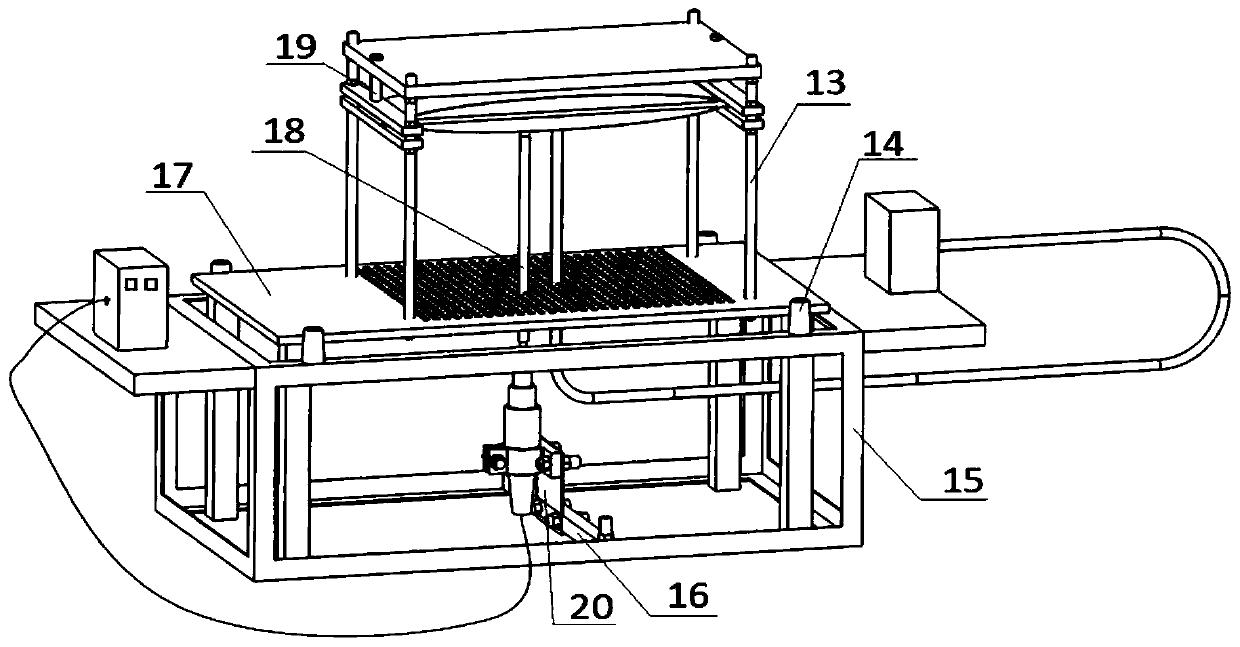

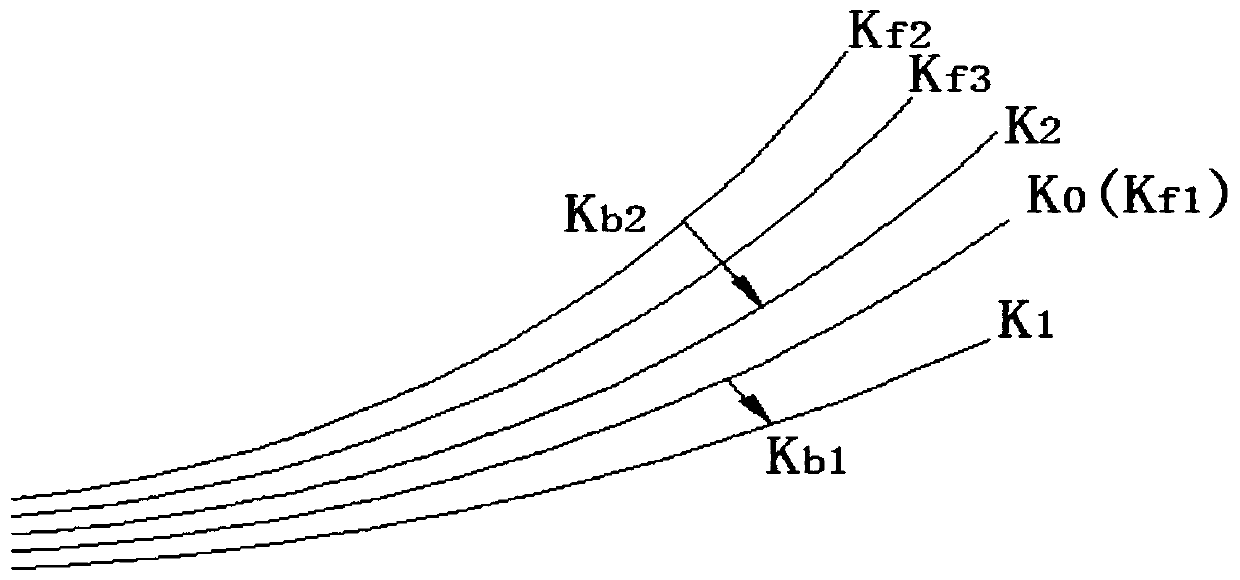

[0042] see figure 1 , figure 2 , Figure 6 and Figure 7 The material of the rib plate part 4 is 7075-T6 aluminum alloy plate, which is prepared by milling into a sample whose specifications are 300mm long, 150mm wide and 15mm thick (the thickness of the thin plate is 2mm, and the height of the rib is 13mm); The radius of curvature of the final forming surface in the length direction of the rib is 2200mm, and the steps of the optimized progressive forming path are 4 times; The air pipe 8 is inserted into the vacuum bag 3 and sealed, and the sealed sample together with the vacuum bag 3 is fixed and locked by the bolt assembly and the bead 5, and the bead 5 is pushed against the bead 5 by the ejector rod 20, so as to avoid friction on both sides of the locked sample. Warpage occurs in the middle, and the M×N tool heads 18 are adjusted at the same time to construct the first mold surface. Then, adjust the position of the suction port of the air pipe 8 so that the upper surfac...

Embodiment 2

[0044] see figure 1 , figure 2 , Figure 5 and Figure 6 , the thin plate material of rib part 4 is 7075-T6 aluminum alloy plate with a thickness of 3mm, and the rib material of rib part 4 is 8090-T8 aluminum-lithium alloy plate with a thickness of 5mm and a height of 16mm, which is welded by friction stir welding to the specification It is 240mm long, 120mm wide, and the total height of the ribs is a thick sample of 19mm; the final forming surface radius of curvature of the sample along the length direction of the ribs is 1200mm, and the optimized progressive forming path step is 6 times; using embodiment 1 Clamp and fix the sample according to the steps in the above; turn on the switch of the vacuum pump, adjust the pressure of the air source, and draw out the vacuum inside the vacuum bag 3, so that the sample fits the first mold surface constructed by the tool head 18, when M When the alarms of ×N tool heads 18 all sound, turn off the switch of the vacuum pump. At this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com