3D (Three-Dimensional) fractured network rock mass two-phase medium seepage test device under stress action

A fracture network rock mass, stress action technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., to achieve the effect of high accuracy, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

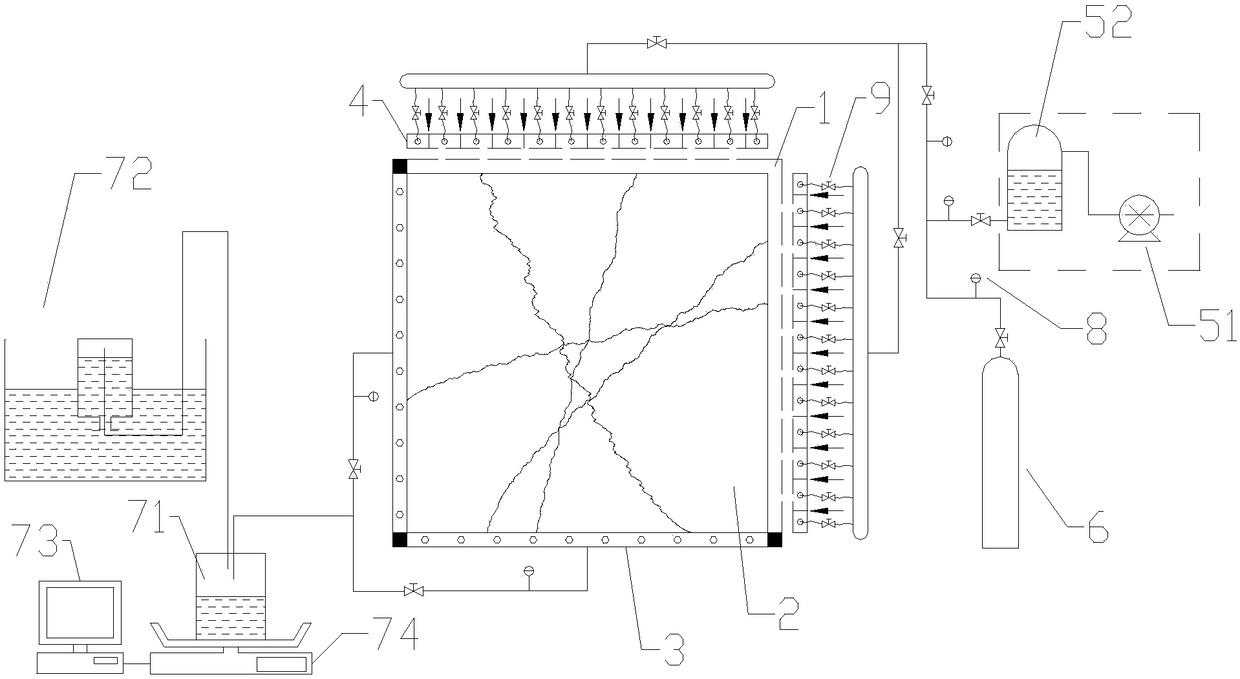

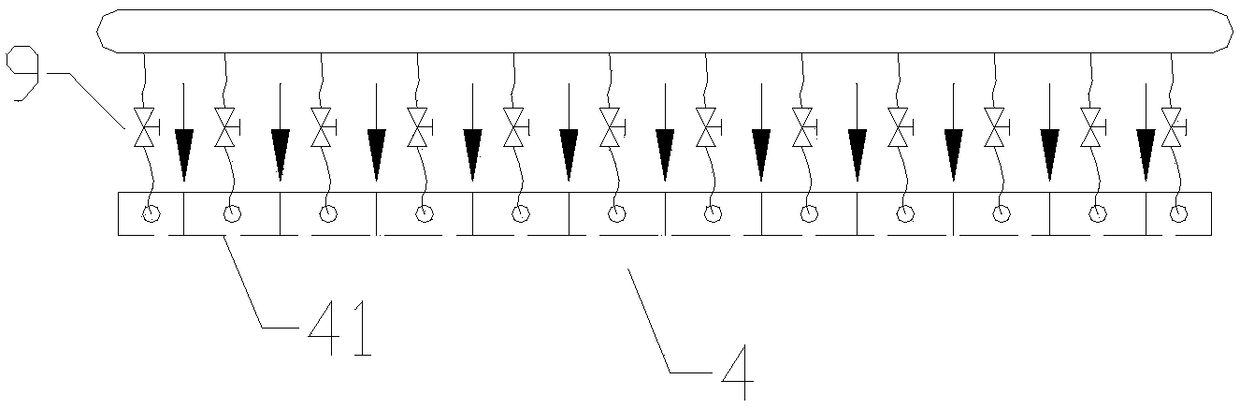

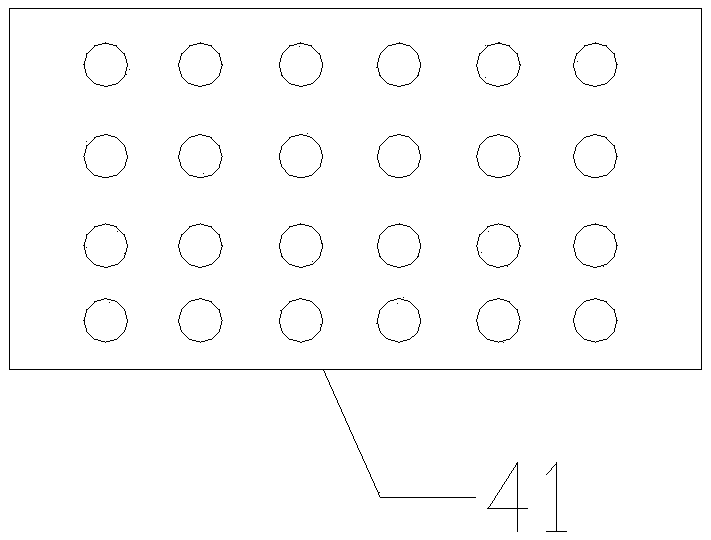

[0028] combine Figure 1 to Figure 6 , a three-dimensional fracture network rock mass two-phase medium seepage test device under the action of stress, including a test platform 1, a liquid-gas loading device, a liquid-gas separation and collection device, and the edge of the test platform 1 is provided with a fixed boundary 3 and a separable The moving loading boundary 4, the fixed boundary 3 and the moving loading boundary 4 form a limit frame for fixing the three-dimensional fractured rock sample 2, and the moving loading boundary 4 is attached to one side of the three-dimensional fractured rock sample 2 There are several small holes, the other side of which is connected with the liquid-gas loading device, so that the liquid-gas loading device is communicated with the small holes, and the fixed boundary 3 is fitted with the three-dimensional fractured rock sample 2. One side is provided with a strip hole 31 (such as Figure 4 and Figure 5 ), its other side is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com