Method and device for manufacturing silicon carbide aluminum-base composite materials with medium to high volume fractions

A silicon carbide-aluminum-based composite material technology, applied in the field of preparation of silicon carbide-aluminum-based composite materials, can solve problems such as the easy collapse of the silicon carbide skeleton, the presence of aluminum strips in the silicon carbide-aluminum-based composite material, and blockage of vent holes, etc., to achieve Uniform microstructure and grain, close to fully dense and stable, and reasonable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Preparation of silicon carbide aluminum matrix composite material with a volume fraction of 45%

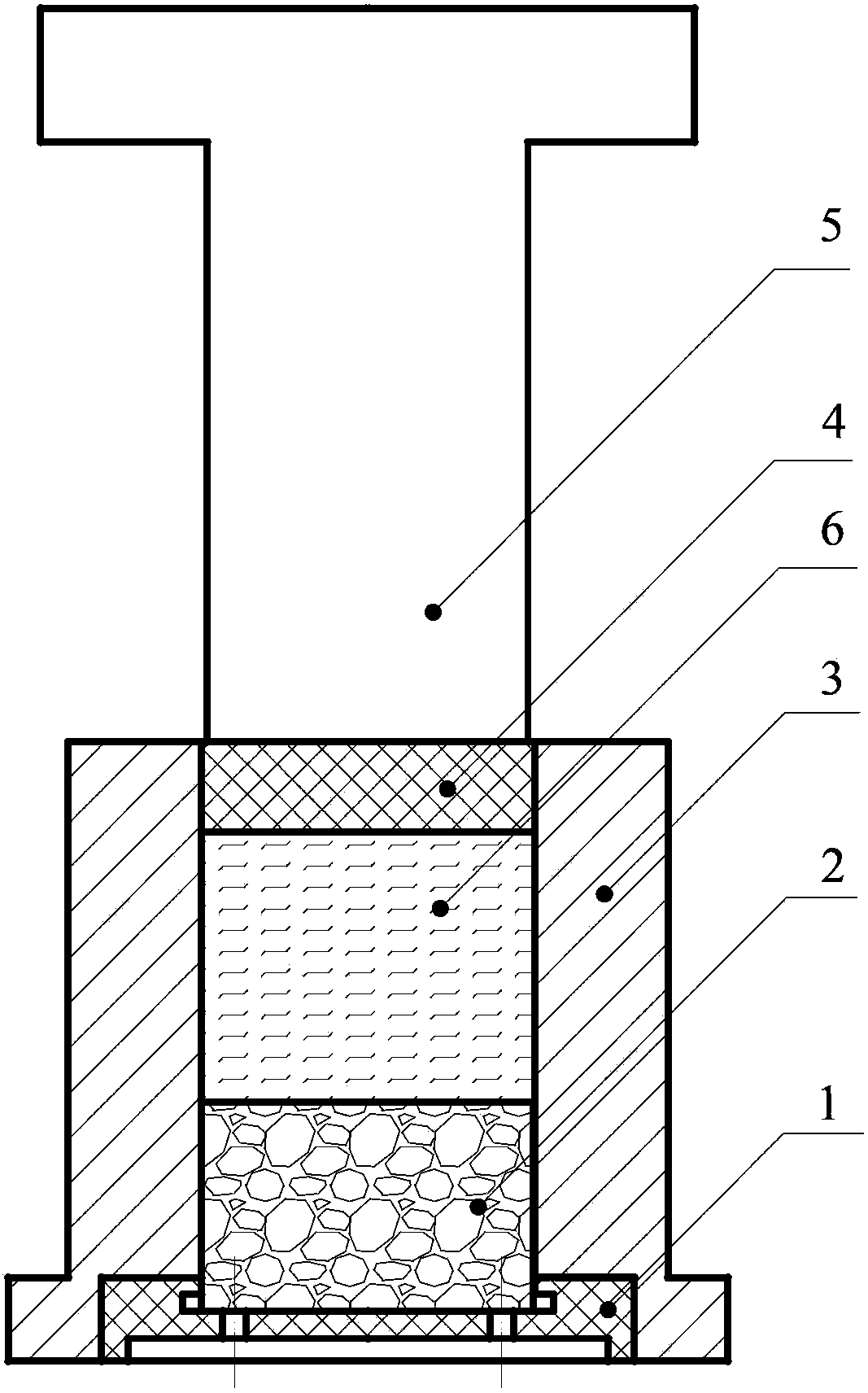

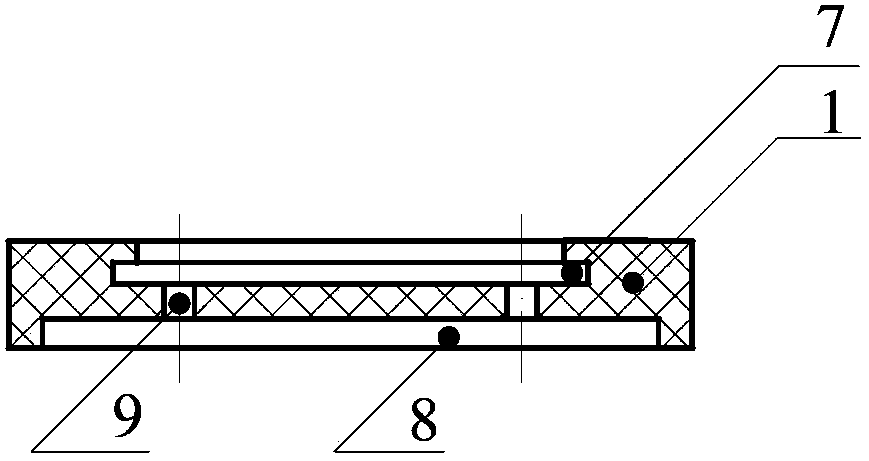

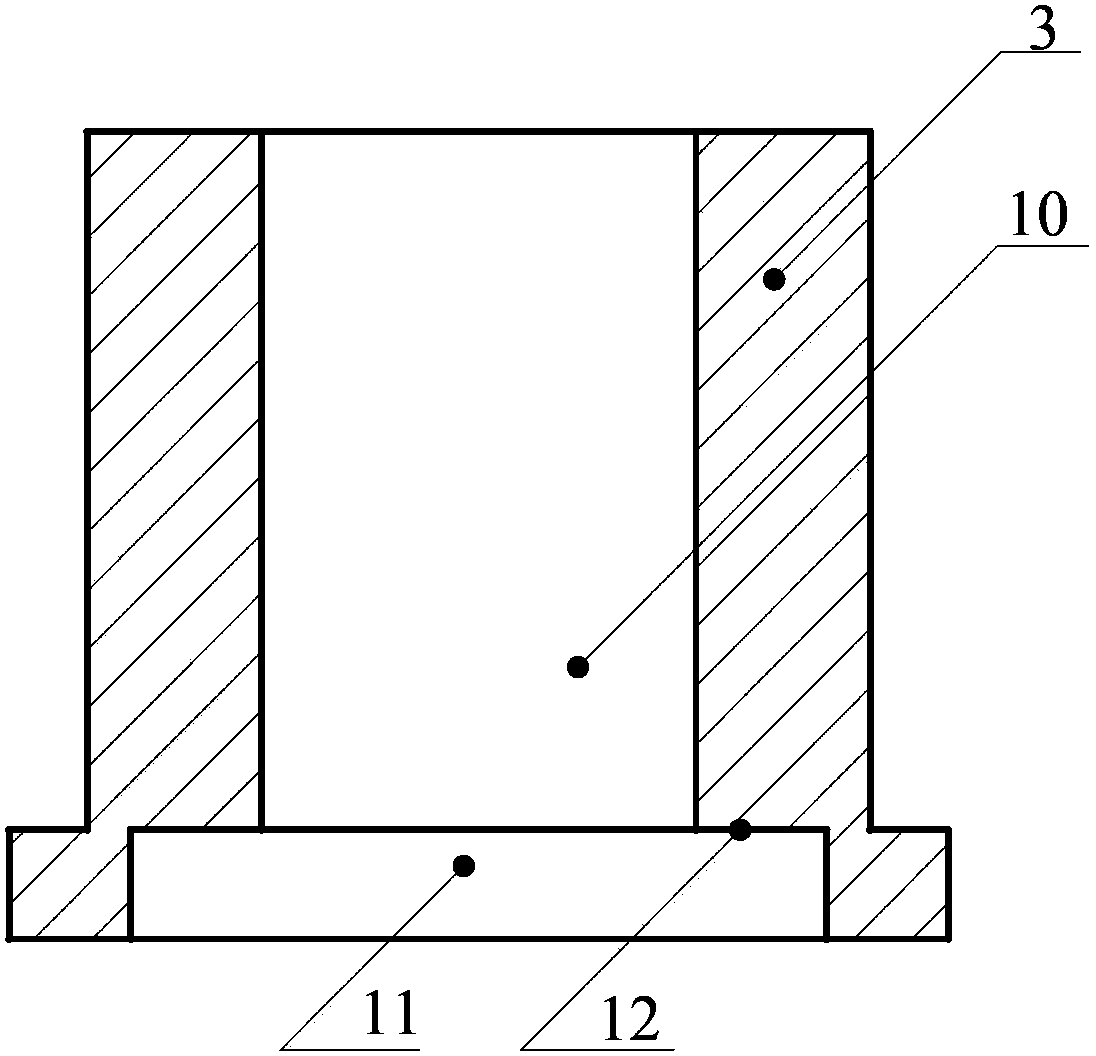

[0042] The pressure casting machine used in the preparation device of the medium-high volume silicon carbide aluminum-based composite material of the present invention and the pressure maintaining / exhausting device specially designed for realizing the method of the present invention, the pressure maintaining / exhausting device includes: graphite base plate 1 , die 3, graphite spacer block 4, punch 5, described die 3 comprises mold cavity 10, matching hole 11, ring 12, and described graphite base plate 1 is provided with step hole 7, buffer hole 8 and exhaust hole 9. The structural relationship of parts is as follows:

[0043] The cavity 10 of the concave mold 3 has a matching hole 11 at its lower part, and a circular ring 12 that acts as a seal above the matching hole 11. The matching hole 11 is an interference fit with the graphite base plate 1, and the cavity 10...

Embodiment 2

[0076] Example 2: Preparation of silicon carbide aluminum matrix composite material with a volume fraction of 60%

[0077] The preparation device is the same as in Example 1.

[0078] Preparation method is the same as embodiment 1 except following process condition:

[0079]The mass ratio of coarse and fine silicon carbide is 1:1.5; the average particle size of coarse silicon carbide is 58 μm, and the mass is 299.6 g; the average particle size of fine silicon carbide is 6.5 μm, and the mass is 499.3 g;

[0080] The pressure for pressing the silicon carbide porous skeleton is 10MPa;

[0081] A silicon carbide aluminum matrix composite material with a volume fraction of 60% was obtained. After testing the performance of the silicon carbide aluminum matrix composite material with a volume fraction of silicon carbide of 60%, the results showed that the flexural strength of the composite material reached 606MPa, and at 25°C to 120°C The coefficient of thermal expansion is 9.8032×...

Embodiment 3

[0082] Example 3: Preparation of silicon carbide aluminum matrix composite material with a volume fraction of 70%

[0083] The preparation device is the same as in Example 1.

[0084] Preparation method is the same as embodiment 1 except following process condition:

[0085] The mass ratio of coarse and fine silicon carbide is 1:0.4; the average particle size of coarse silicon carbide is 58 μm, the mass is 624.1 g, the average particle size of fine silicon carbide is 6.5 μm, and the mass is 249.6 g.

[0086] The pressure for pressing the silicon carbide porous framework is 15MPa

[0087] A silicon carbide aluminum matrix composite material with a volume fraction of 70% was obtained. After testing the performance of the silicon carbide aluminum matrix composite material with a volume fraction of silicon carbide of 70%, the results showed that the flexural strength of the composite material reached 542MPa, and at 25°C to 120°C The coefficient of thermal expansion is 6.8721×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com