High-accuracy numerical control eight-axle helical compression spring former

A compression spring, high-precision technology, which is applied in the direction of manufacturing springs, other household appliances, household appliances, etc. from wires, can solve the problems that high-precision springs cannot be satisfied, technical effects cannot be achieved, and springs are prone to tail hooks, etc., to improve product quality. Quality and production efficiency, improved performance and reliability, fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

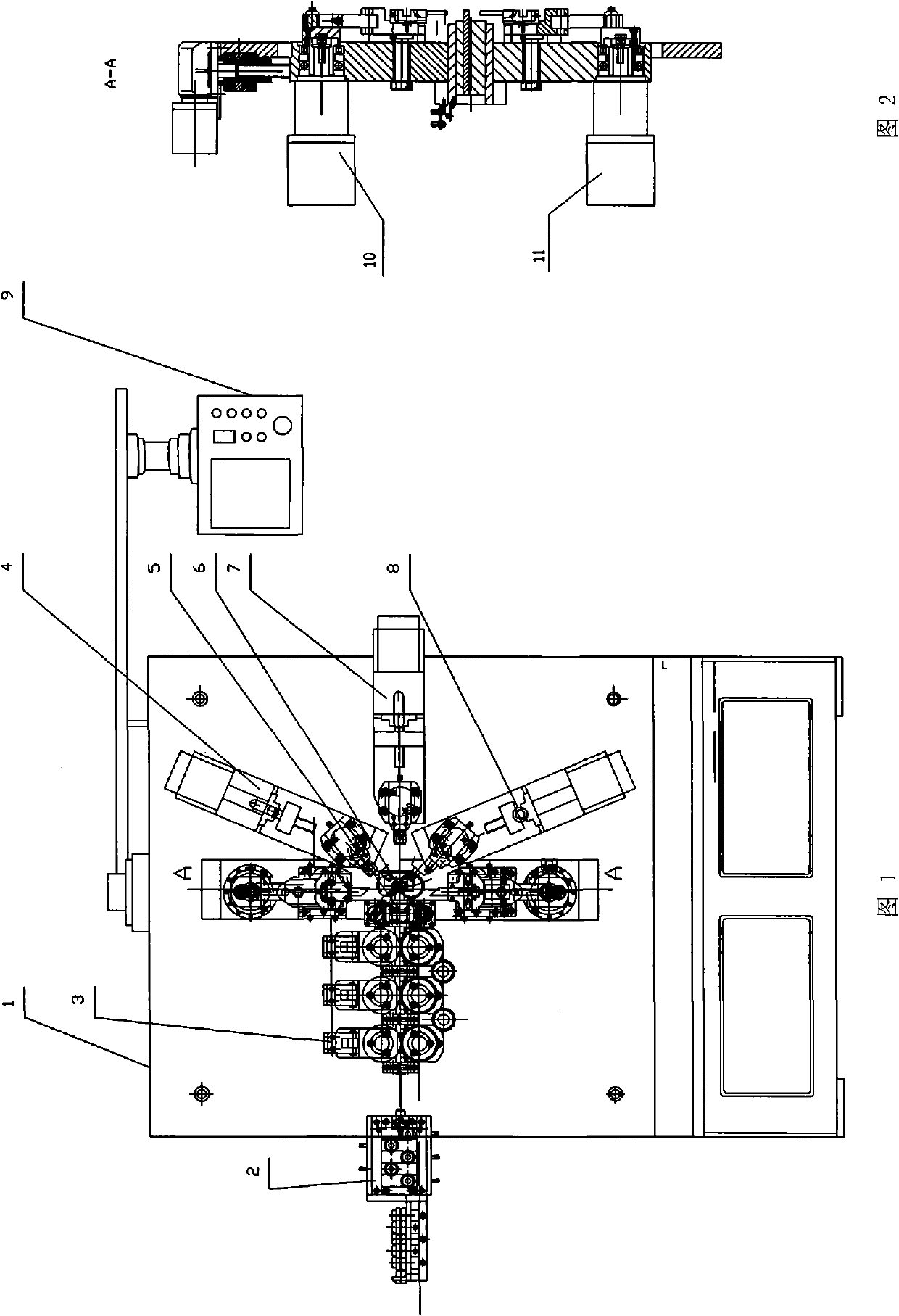

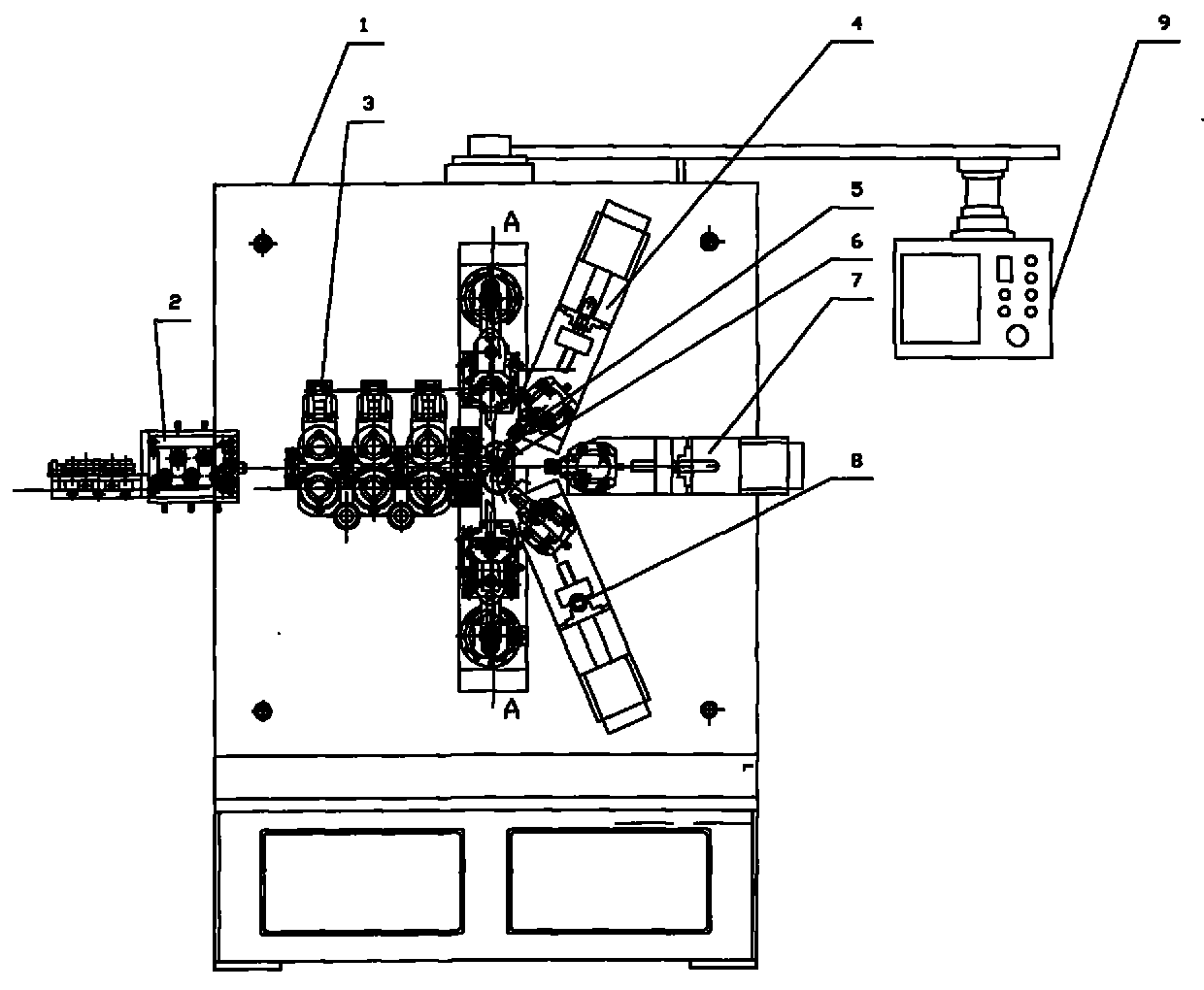

[0011] exist figure 1 , among Fig. 2: machine tool main body 1 is the cuboid frame type that welds with steel plate, and the lower end is provided with base; There is a cutting mechanism, which is divided into an upper cutting mechanism 10 and a lower cutting mechanism 11; a pitch mechanism 5 is provided on the left side of the mandrel 6 and the right side of the compression feeding mechanism 3; an upper diameter reducing mechanism 4 is provided on the upper right of the mandrel 6, The middle diameter reducing mechanism 7 is arranged in the middle of the right, and the lower diameter reducing mechanism 8 is arranged on the lower right; a compression feeding mechanism 3 and a straightening mechanism 2 are arranged on the left side of the mandrel 6, and a pipe joint is arranged on the compression feeding mechanism 3. It is connected with the air pipe of the air compressor, and each of the eight axes is equipped with an independent servo motor. The circuit of the servo motor is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com