Weaving Welding Forming Method of Large Circulation Pump Impeller

A forming method and circulation pump technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex processing technology, low cost, and high precision of casting impellers, and achieve simple structure, short production cycle, and high welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

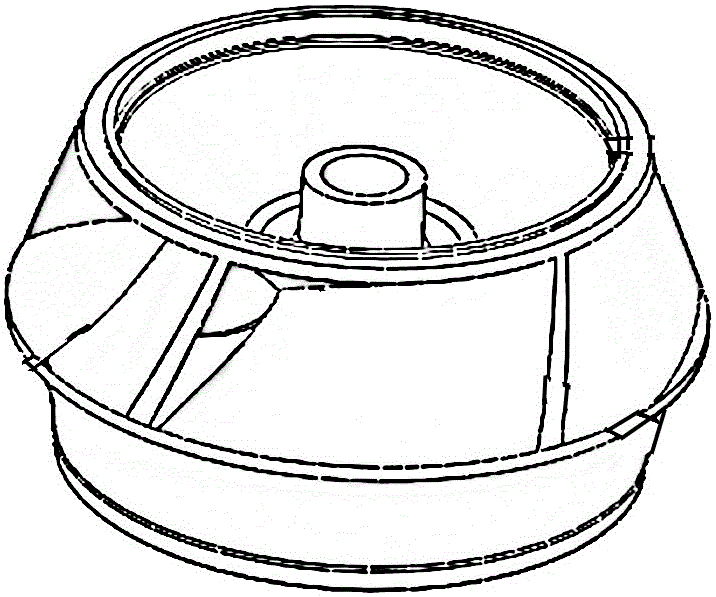

[0040] The impeller takes five blades as an example, as shown in the figure, and the specific steps are as follows.

[0041] The first step is to make models of the impeller front cover, blades and impeller rear cover respectively, and cast the castings.

[0042] In the second step, the surface of the flow-through part of the front and rear cover plates is finished to the finished product size, the outer surface and the end face are rough-machined, and a 5-8mm finishing allowance is reserved.

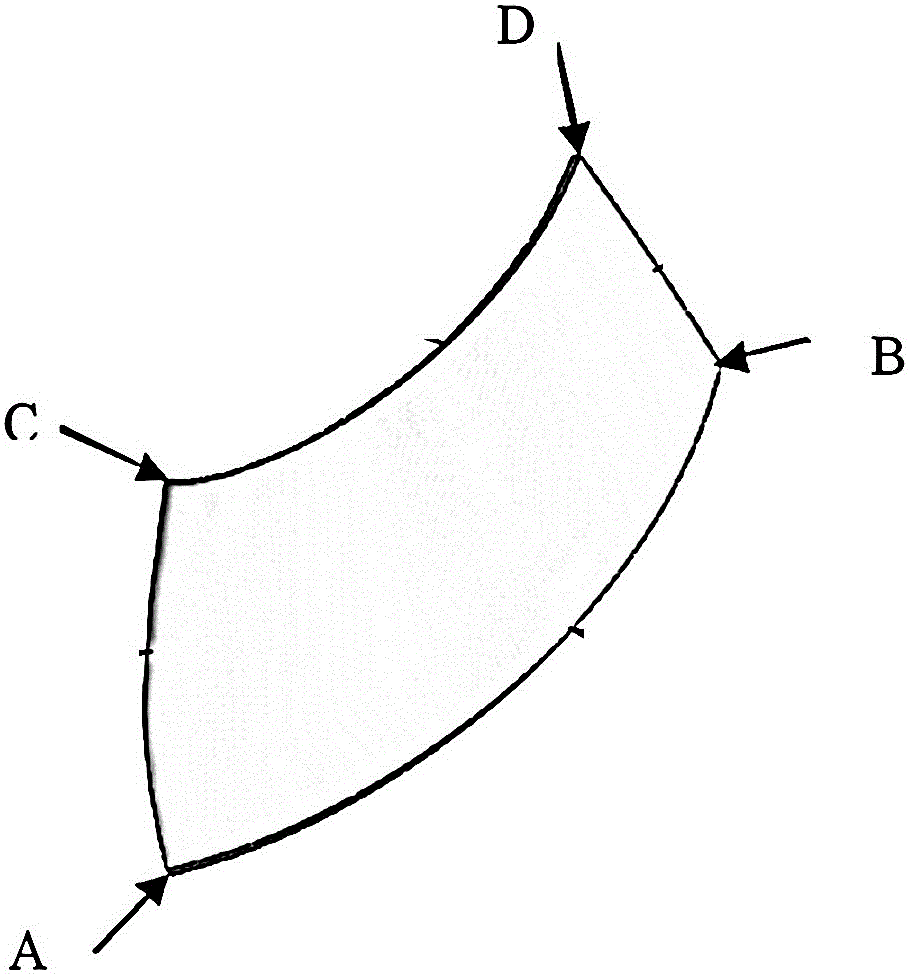

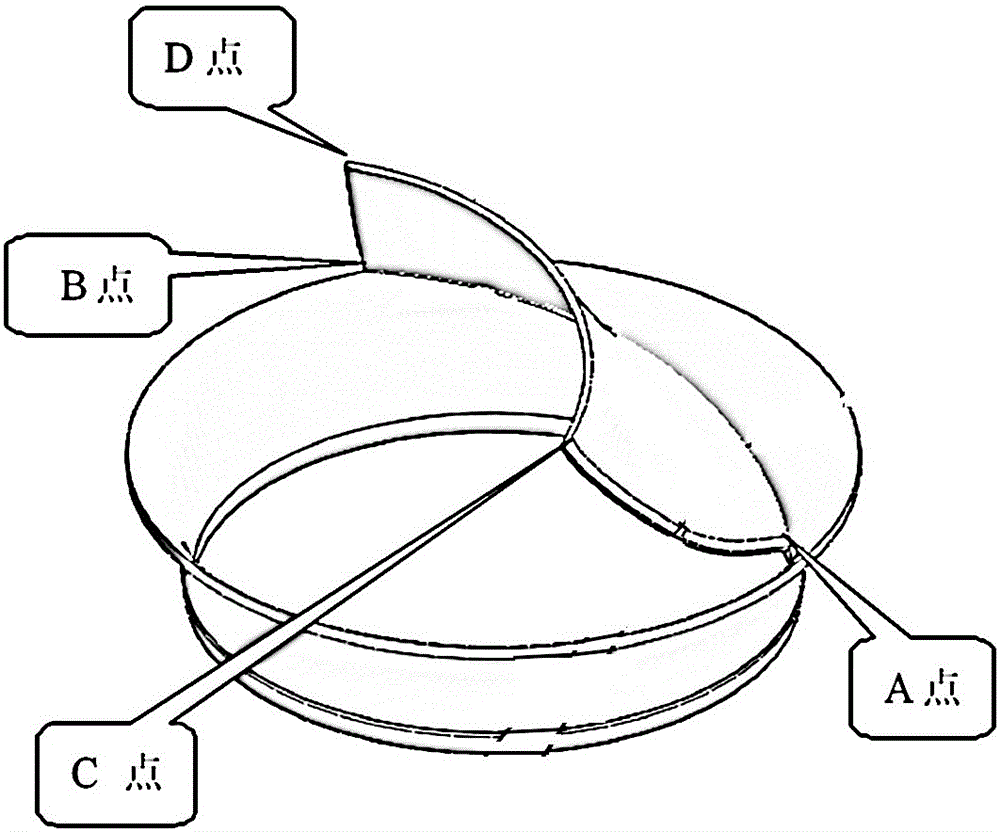

[0043] The third step is to polish the working surface and the back of the blade, and use the space model made by the contour line to check the curvature of the polished shape line, and determine the reference points A, B, C, and D of the four corners of the blade. Point A is the blade on the front cover. Point B is the placement position of the blade at the outlet of the front cover; point C is the placement position of the blade at the suction inlet of the rear cover; point D is the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com