Central shaft cutting-off mechanism for eight-shaft spring forming machine

A technology of cutting mechanism and shaft spring, which is applied in the direction of manufacturing springs, other household appliances, household appliances, etc. from wires, can solve the problems of not achieving the ideal technical effect, the mandrel is slightly moved, and the spring is prone to tail hooks, etc., so as to improve the product quality. The effect of quality and production efficiency, improving work efficiency, improving performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

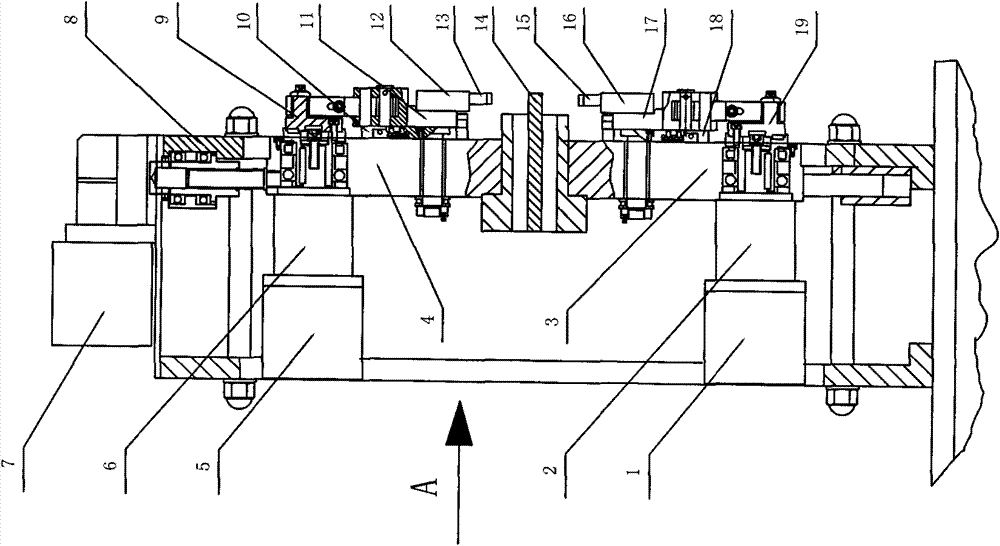

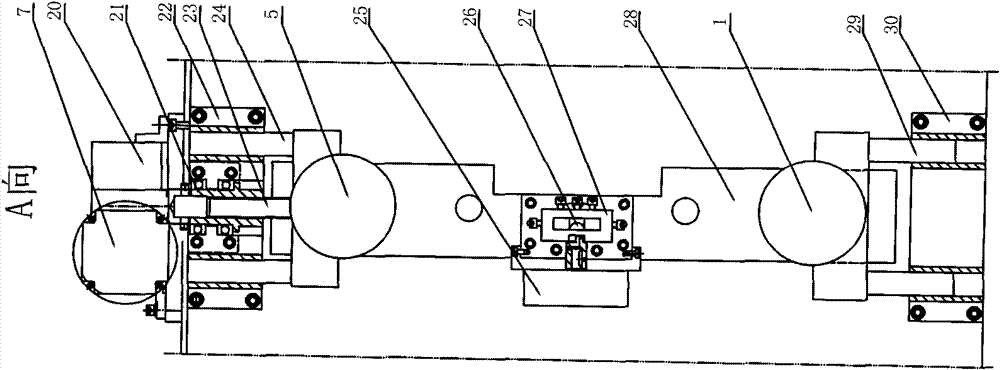

[0011] exist figure 1 , figure 2 Middle: The front wall panel 8 and the rear wall panel are connected with long bolts to form a rectangular support body, a servo motor 7 is arranged on the upper end of the support body, the servo motor 7 is connected with the reduction box 20, and the front wall panel 8 is provided with a rectangular support body. Groove, the core block 28 is arranged in the groove, fixed by the lifting nut 21, the core block 28 is in a rectangular shape, the lifting shaft 23 connects the reduction box 20 and the core block 28, and the upper guide sleeve seat 22 is respectively provided on both sides of the lifting shaft 23 , the upper guide column 24 is installed in the upper guide sleeve 22, the bottom end of the support body is provided with two lower guide sleeves 30, the lower guide sleeve 30 is respectively provided with a lower guide column 29, and the middle part of the core block 28 is provided with a rectangular hole, the rear of the rectangular ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com