Mini-type sliding block

A slider and miniature technology, which is applied in the field of machinery, can solve the problems of high efficiency and high precision in the precision and manufacturing process, high scrap rate and unqualified quantity, complex machining process, etc., to improve the precision of the slider and verticality, smooth coordination and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

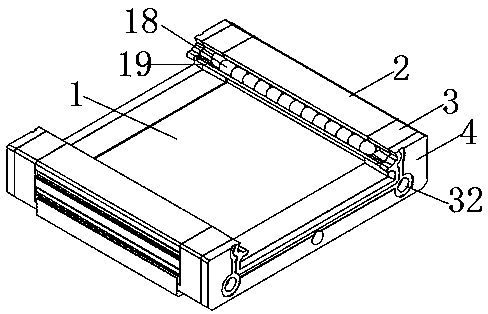

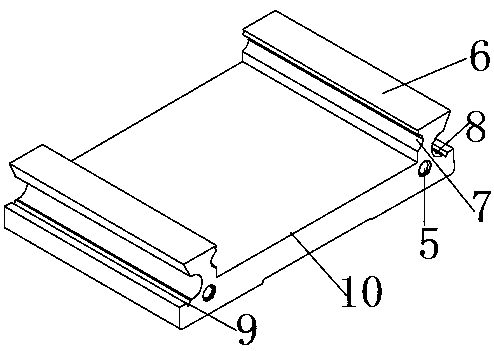

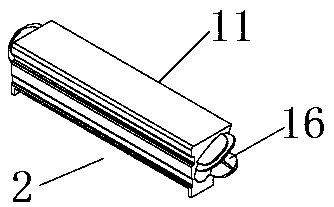

[0027] Such as Figure 1-8 As shown, this specific embodiment adopts the following technical solutions: a miniature slider, including a fixing mechanism 1, a return mechanism 2, a sealing mechanism 3 and a gear mechanism 4, and the two sides of the fixing mechanism 1 are clamped with a return mechanism 2, the two ends of the return mechanism 2 are fixedly connected with a sealing mechanism 3, and the side of the sealing mechanism 3 away from the return mechanism 2 is fixedly connected with a stall mechanism 4, and the fixing mechanism 1 is connected by the first The hole 5, the mounting frame 6, the first raceway 7, the first connecting slot 8, the guide rail groove 9 and the fixed plate 10 are composed of two ends of the fixed plate 10, which are fixedly connected with the mounting frame 6, and the mounting frame 6 A first connection card slot 8 is dug away from the side of the fixed plate 10, and a guide rail groove 9 is dug on one side of the installation frame 6 and below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com