Casting method, upper mold assembly, and method for fixing core to the upper mold

A fixing method and assembly technology, which is applied in the field of casting manufacturing, can solve the problems of finished product shape defects, core floating, etc., and achieve the effects of improving productivity, uniform metal structure of castings, and reducing component costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

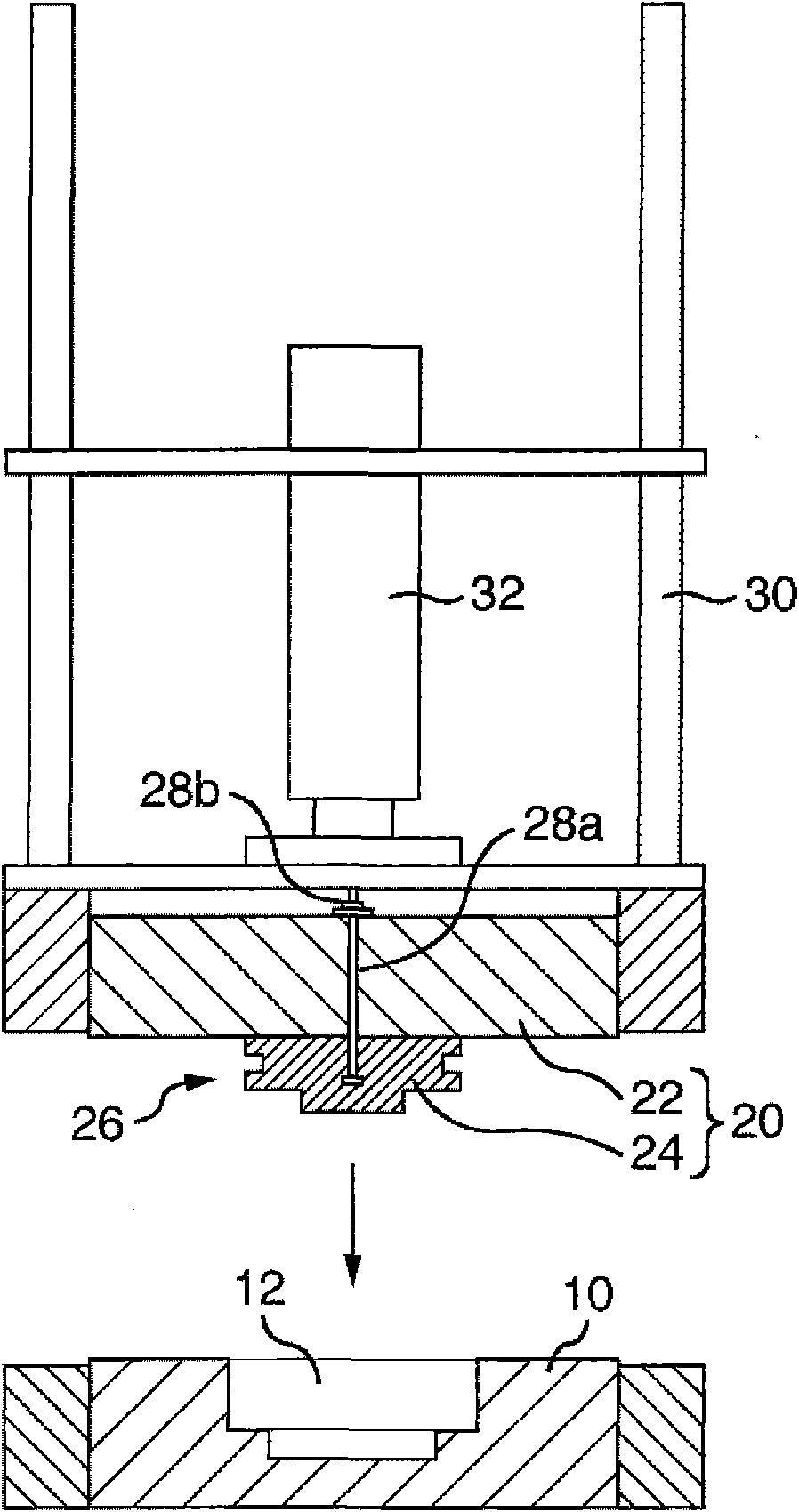

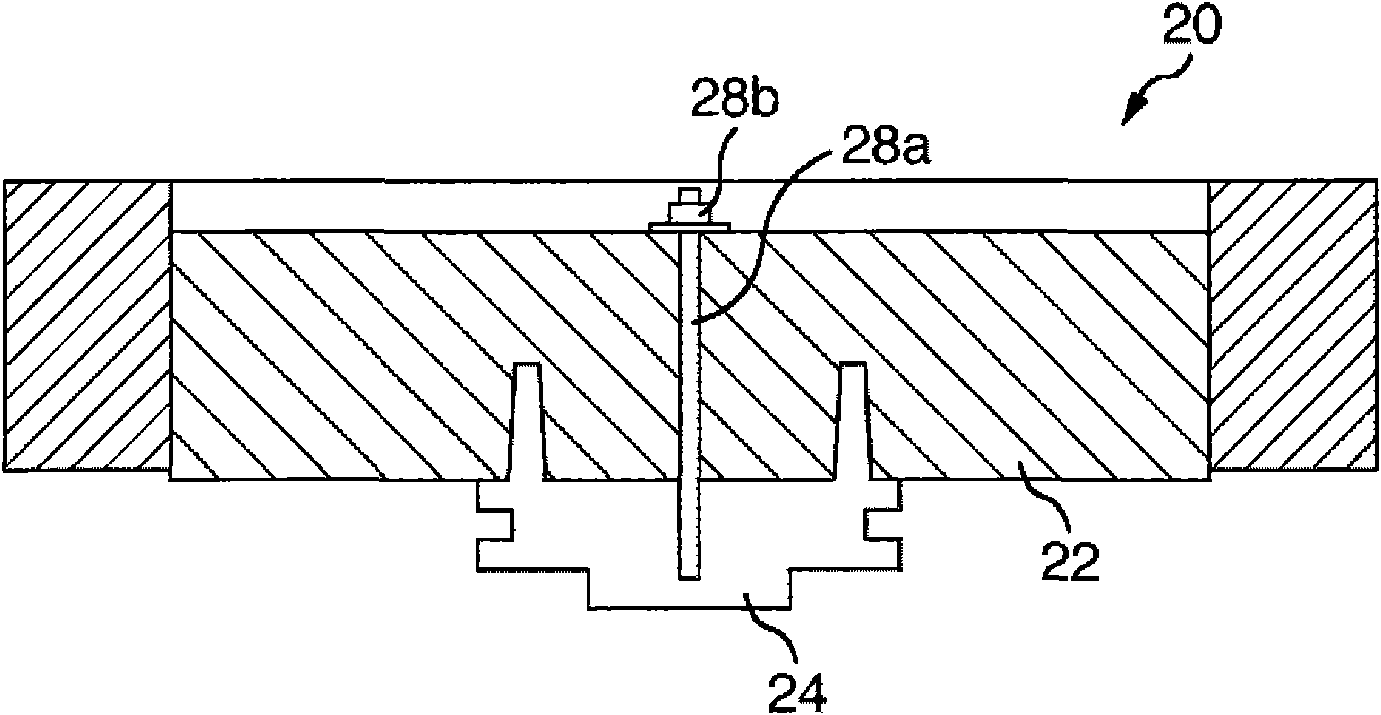

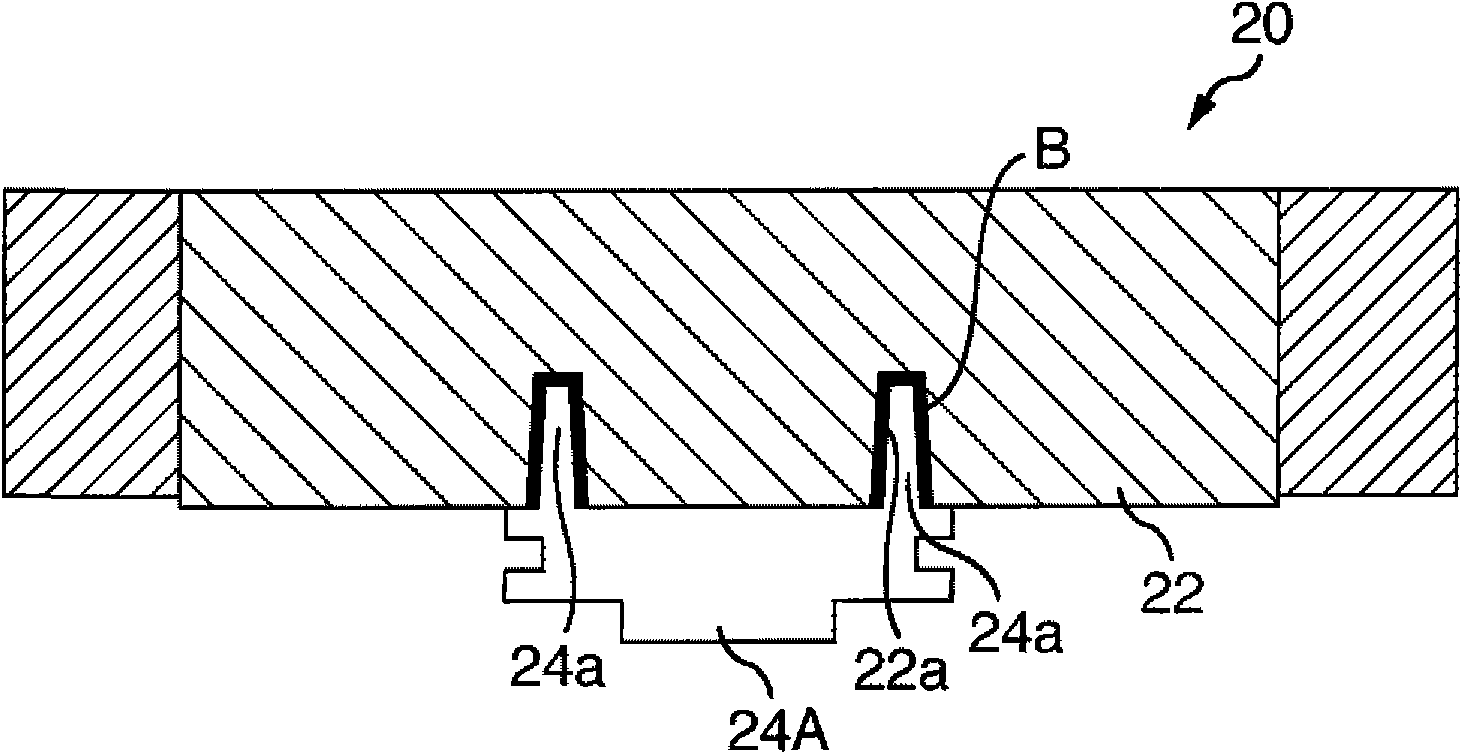

[0057] figure 1 It is a longitudinal cross-sectional view of a casting device including a lower mold 10 and an upper mold assembly 20 schematically showing one embodiment of the present invention.

[0058] The lower mold 10 has a recess 12 corresponding to a part of the finished outline shape of the cast product. When the upper mold 22 is matched with the lower mold 10, the recess 12 outlines the cavity of the mold. The upper mold assembly 20 is fixedly assembled on the lower surface of the upper mold 22 with a core 24 forming a protruding portion 26 of the upper mold assembly 20 which, together with the above-mentioned recess 12, defines the finished product. outline shape.

[0059] For making the upper mold assembly 20 through the combination of the upper mold 22 and the core 24, the fixation of the core 24 relative to the upper mold 22 can be carried out by the following bonding methods, that is, mechanical bonding, bonding, etc. Bonding, bonding by friction, and bonding...

Embodiment 2

[0077] The examples described below show examples of joining of the core to the upper mold using frictional force.

[0078] Such as Figure 10 The core 40 placed on the core support 58 of the core mounting device 50 is positioned at a position facing the upper mold 60 positioned above it. The core 40 has a rod-shaped fitting protrusion 42 at the center of the top surface, and the rod-shaped fitting protrusion 42 is pressed into a recessed part 62 formed at the center of the lower surface of the upper mold 60. The friction fit relationship between the parts 62 makes the core 40 installed and fixed on the upper mold 60 .

[0079] The core installation device 50 is mainly composed of the following components, that is, a frame 90 supported on a base (not shown), a guide rod 52 slidably arranged on the frame 90, and a lower part supported by the frame. 90 supports the driving cylinder (pneumatic, hydraulic or electric) device 54 whose upper part is combined with the frame 100 ere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com