Tool and method for fine machining of workpieces

A tool and workpiece technology, applied in the field of workpiece cutting and finishing, can solve the problems of insufficient tool life, lack of manufacturing accuracy of tools and methods, and inability to extend the axes of rotation precisely and coaxially with each other, to achieve precise dimensional accuracy and high surface The effect of smoothness and long tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

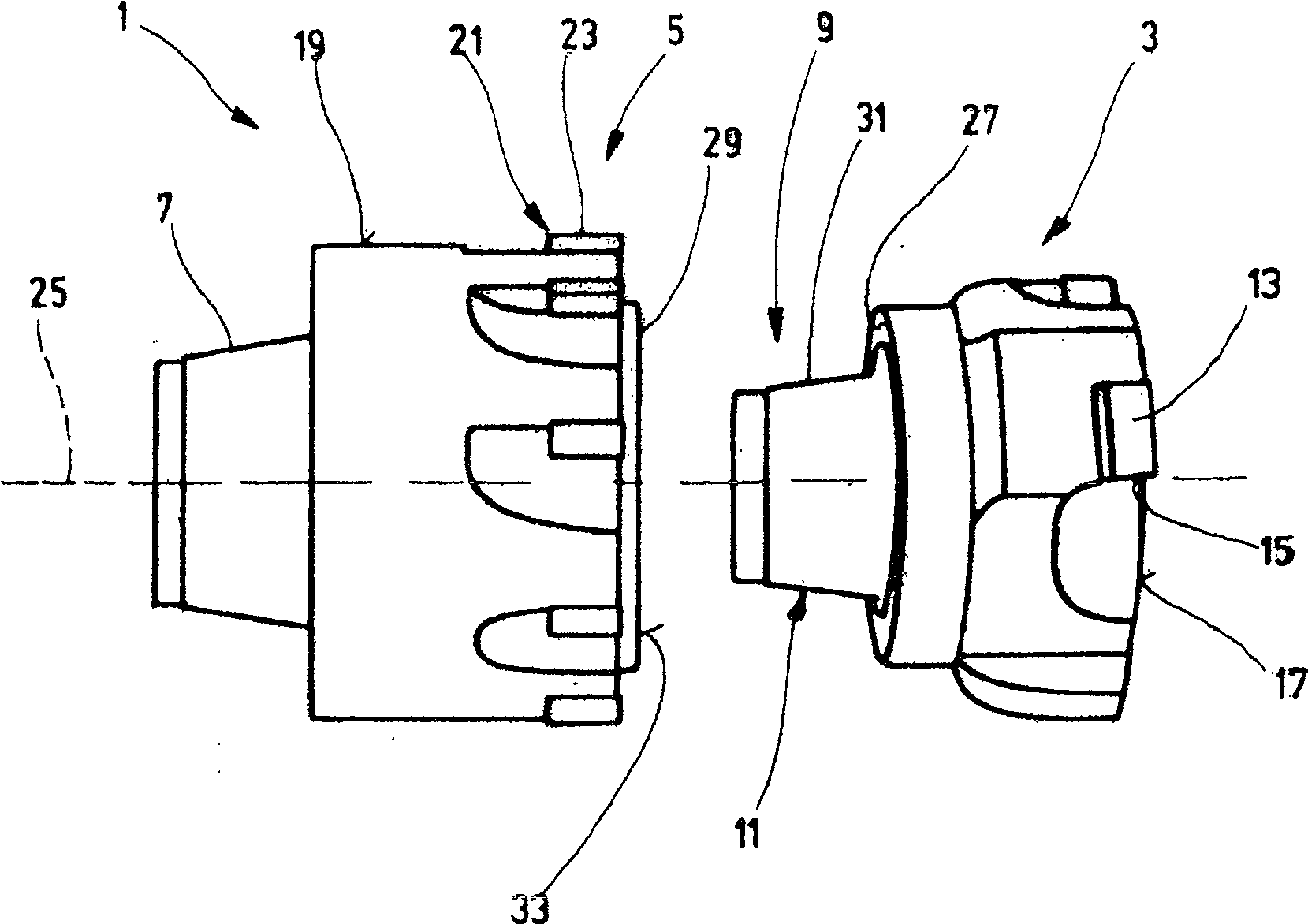

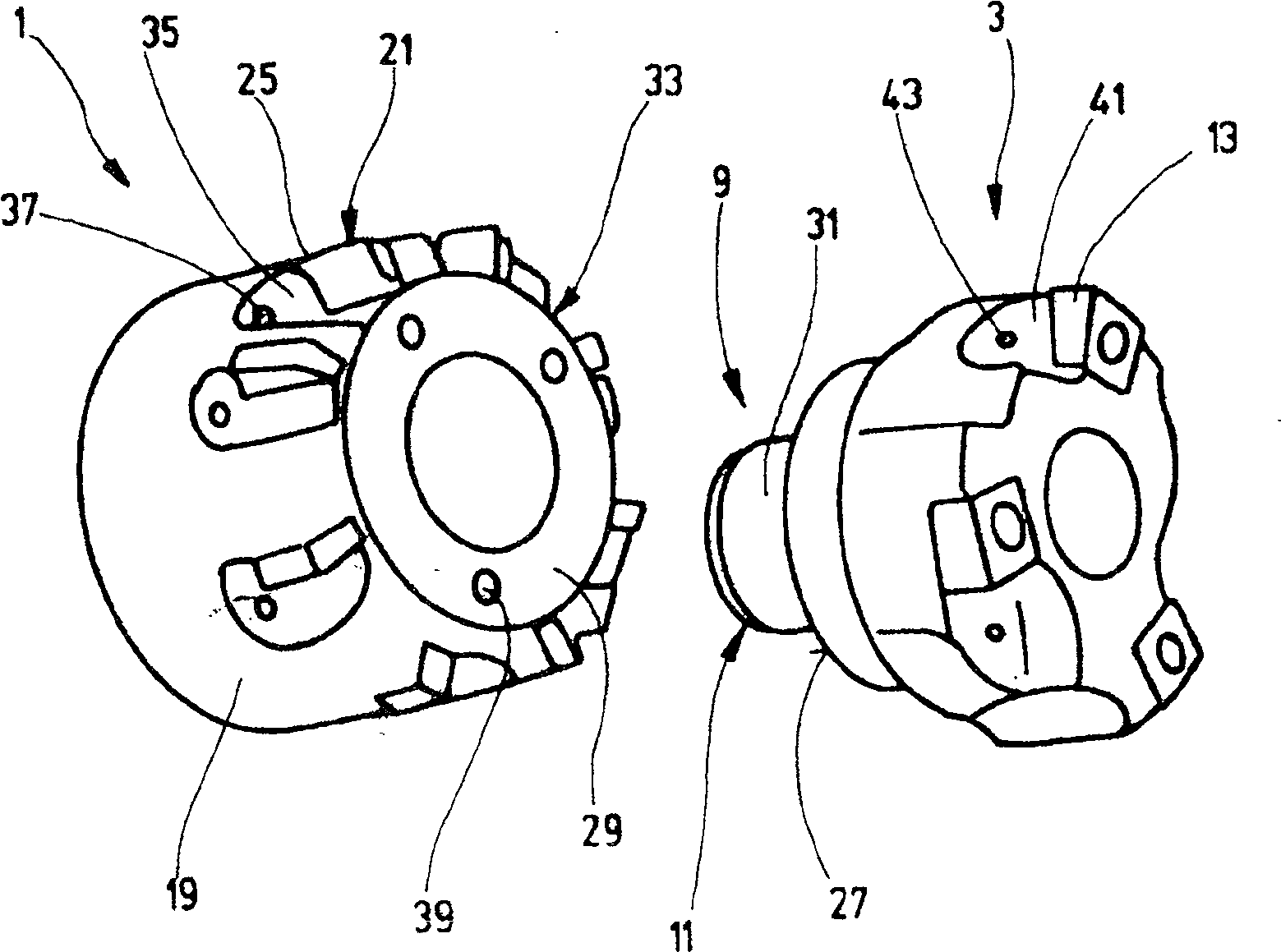

[0018] figure 1 A first exemplary embodiment of a tool 1 is shown which is used for the finishing machining of workpieces and which has a preliminary machining stage 3 and a finishing machining stage 5 .

[0019] The tool 1 can be connected in a suitable manner directly or via an intermediate piece, an adapter or the like to a machine tool, for example via a tapered shaft 7 which engages in a tool receiving hole and is clamped in a suitable manner therewith.

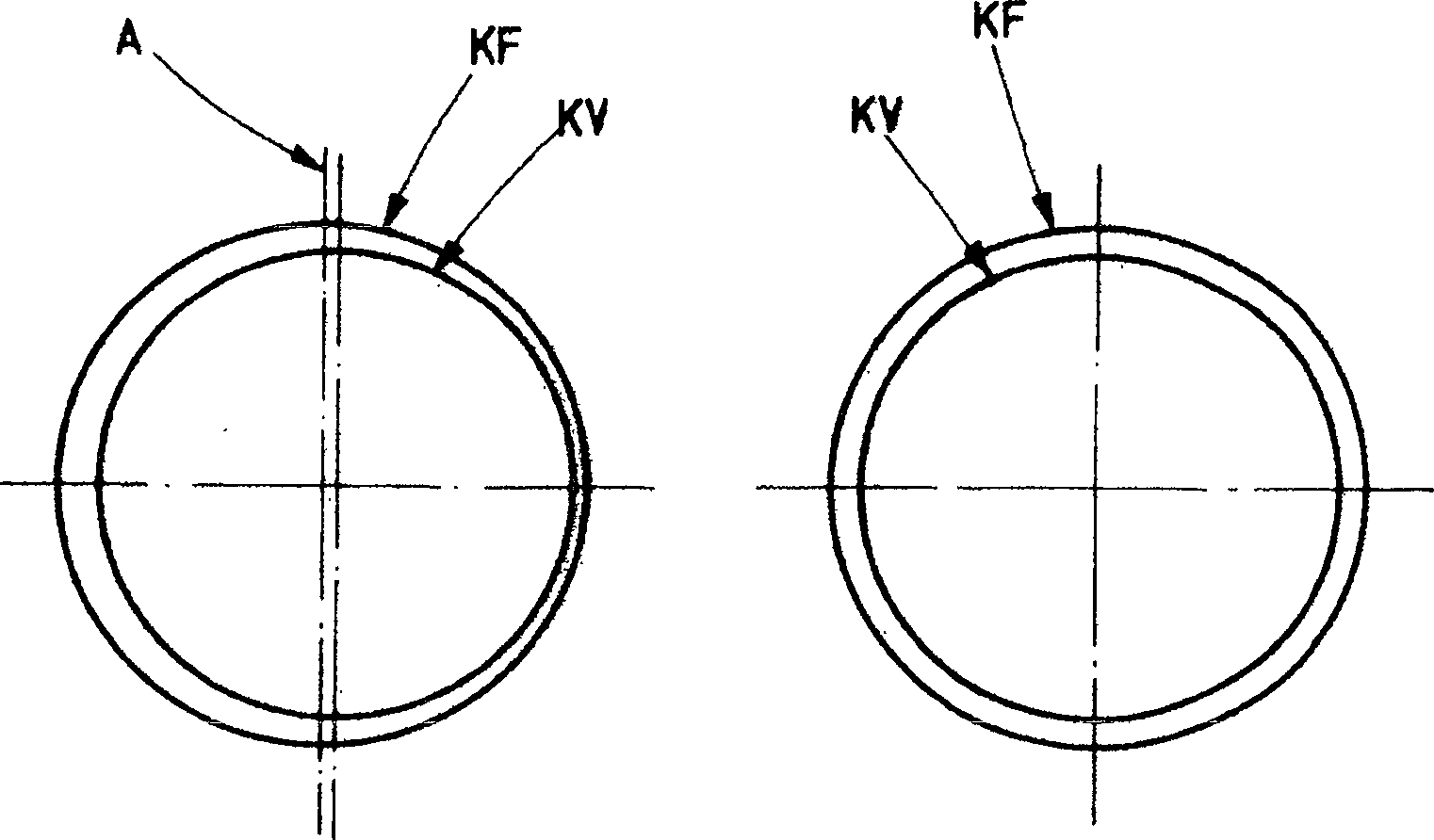

[0020] The preliminary machining stage 3 and the finishing machining stage 5 are fixedly connected to one another via a connection 9 which has a device 11 by means of which the relative position of the two stages can be influenced. It should set stages 3 and 5 coaxially with each other as much as possible. The interface 9 thus serves to connect the stages 3 and 5 of the tool 1 to each other such that the center axes of the two stages 3 and 5 coincide with each other and with the center axis 25 of the tool 1 . With the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com