Reducing mechanisms for eight-axis spring forming machine

A technology of forming machine and shaft spring, applied in the field of reducing mechanism of eight-axis spring forming machine, can solve the problems of low spring quality and production efficiency, unable to achieve technical effect, difficult to form, etc., to reduce the amount of manual operation, improve performance and reliability High performance and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

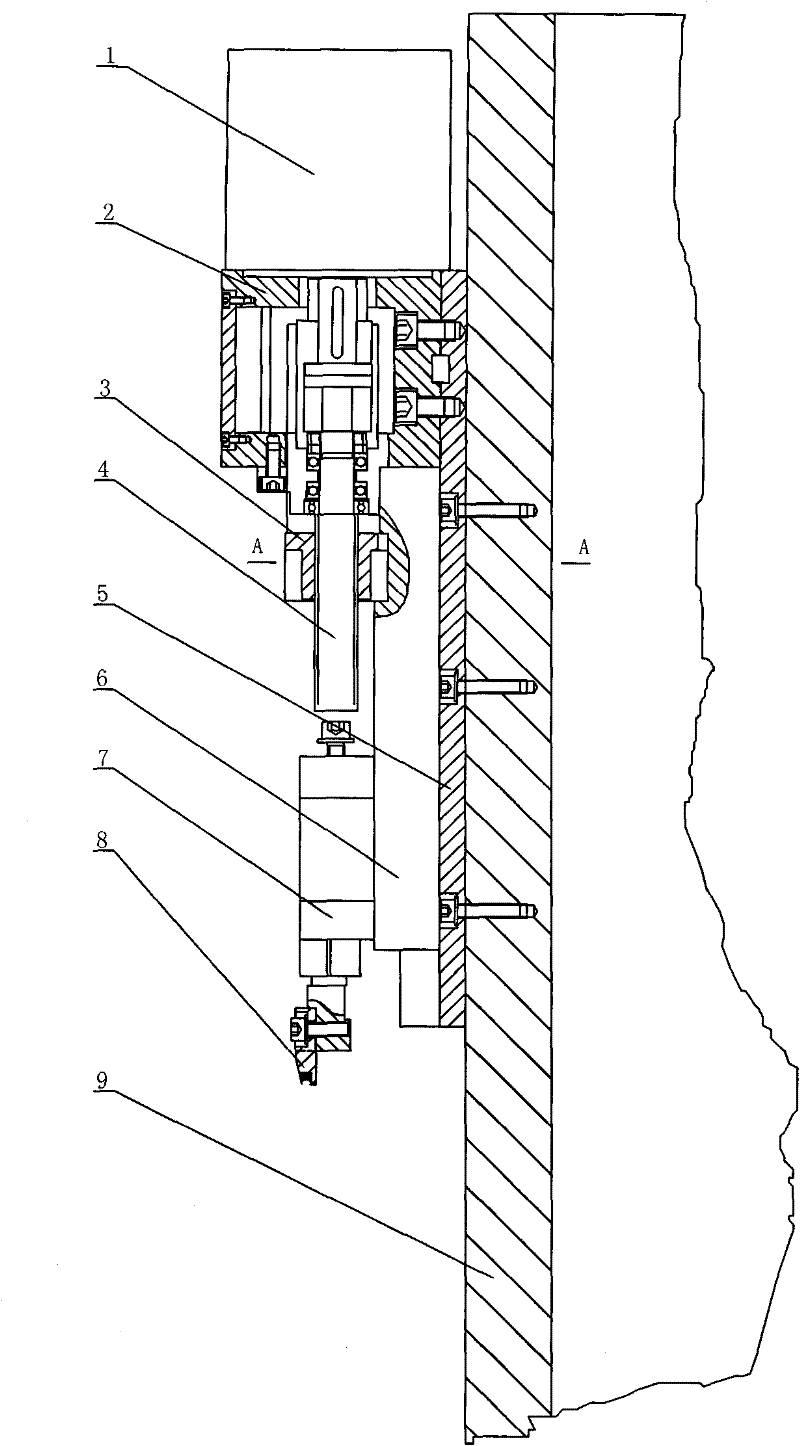

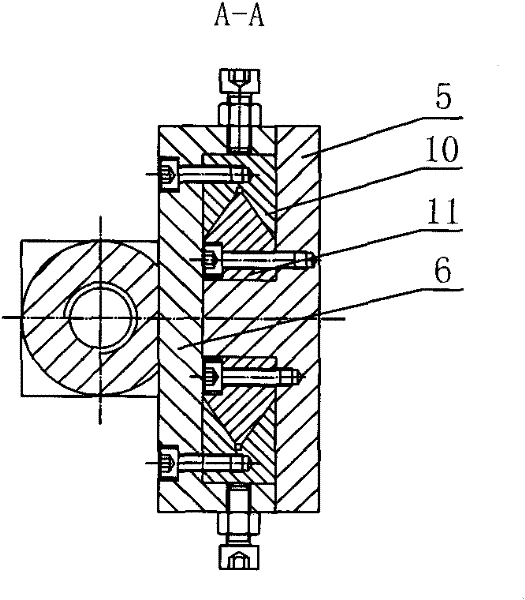

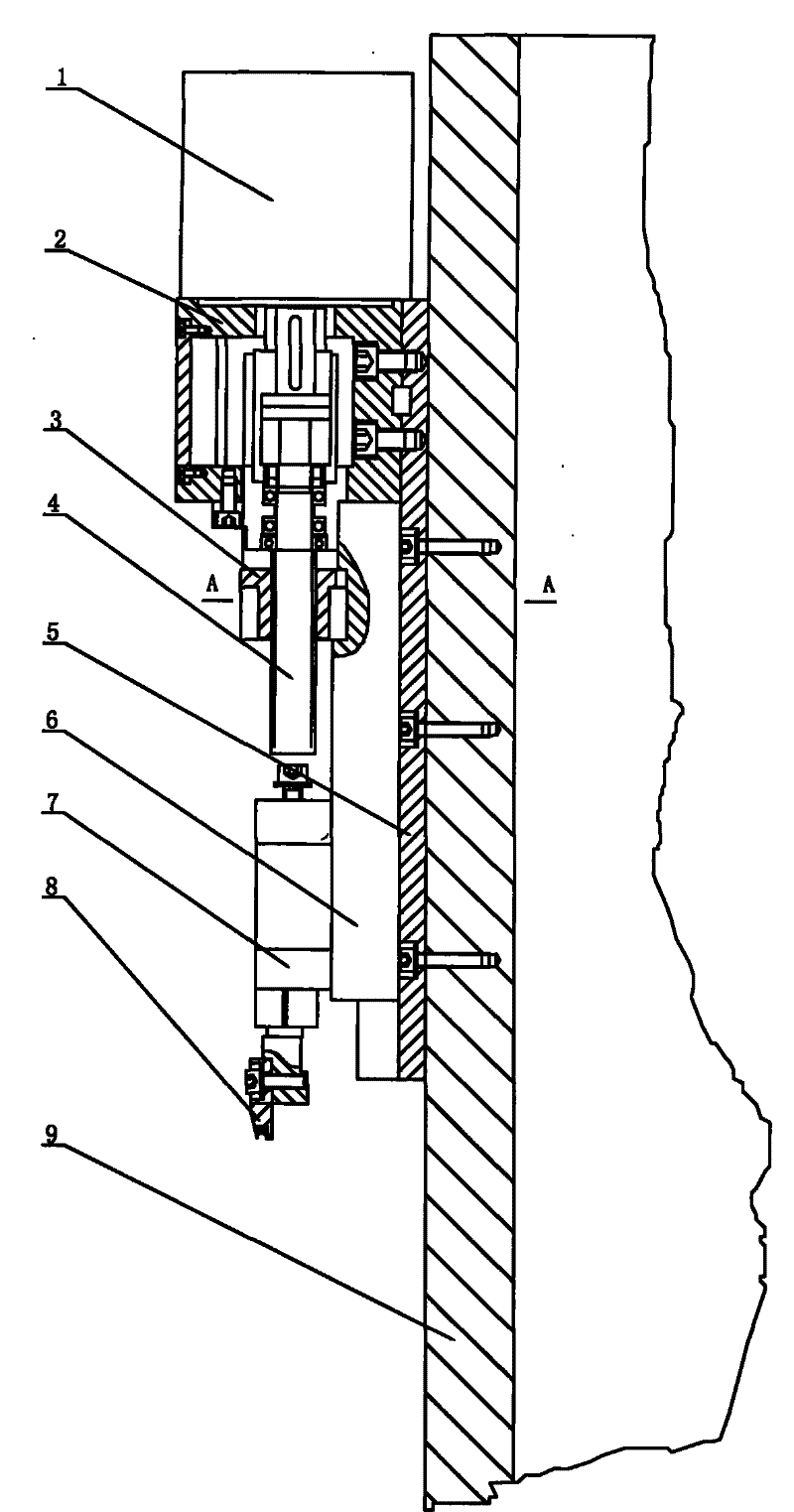

[0011] exist figure 1 , figure 2 Middle: There is a slider seat 5 on the front wall plate 9, and a bracket 2 is arranged on the top of the slider seat 5, which are all fixed by bolts. The servo motor 1 and the ball screw 4 are installed on the bracket 2, and the ball screw 4 passes through the connecting shaft. Connected with the servo motor 1, under the bracket 2, a slider 6 is provided on the surface of the slider seat 5, and a 70° convex V-block 11 and a 70° concave V-block 10 are arranged between the slider seat 5 and the slider 6. The concave and convex parts of the two kinds of V blocks match each other. The ball screw nut 3 is fixed on the slider 6 by bolts. 8. The diameter reducing mechanism is composed of upper, middle and lower parts, each of which is equipped with a servo motor 1, and the upper, middle and lower diameter reducing mechanisms are all set on the front wall panel 9 of the whole machine, forming an eight-axis spring forming Machine variable diameter m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com