Tungsten steel push rod and machining method thereof

A technology of tungsten steel push rod and processing method, which is applied in the field of tungsten steel push rod and its processing, can solve the requirement that the tungsten steel push rod cannot meet the accuracy requirement, the tungsten steel push rod cannot be assembled or used, the tungsten steel push rod two Problems such as sub-processing, to achieve the effect of low production cost, high dimensional accuracy and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

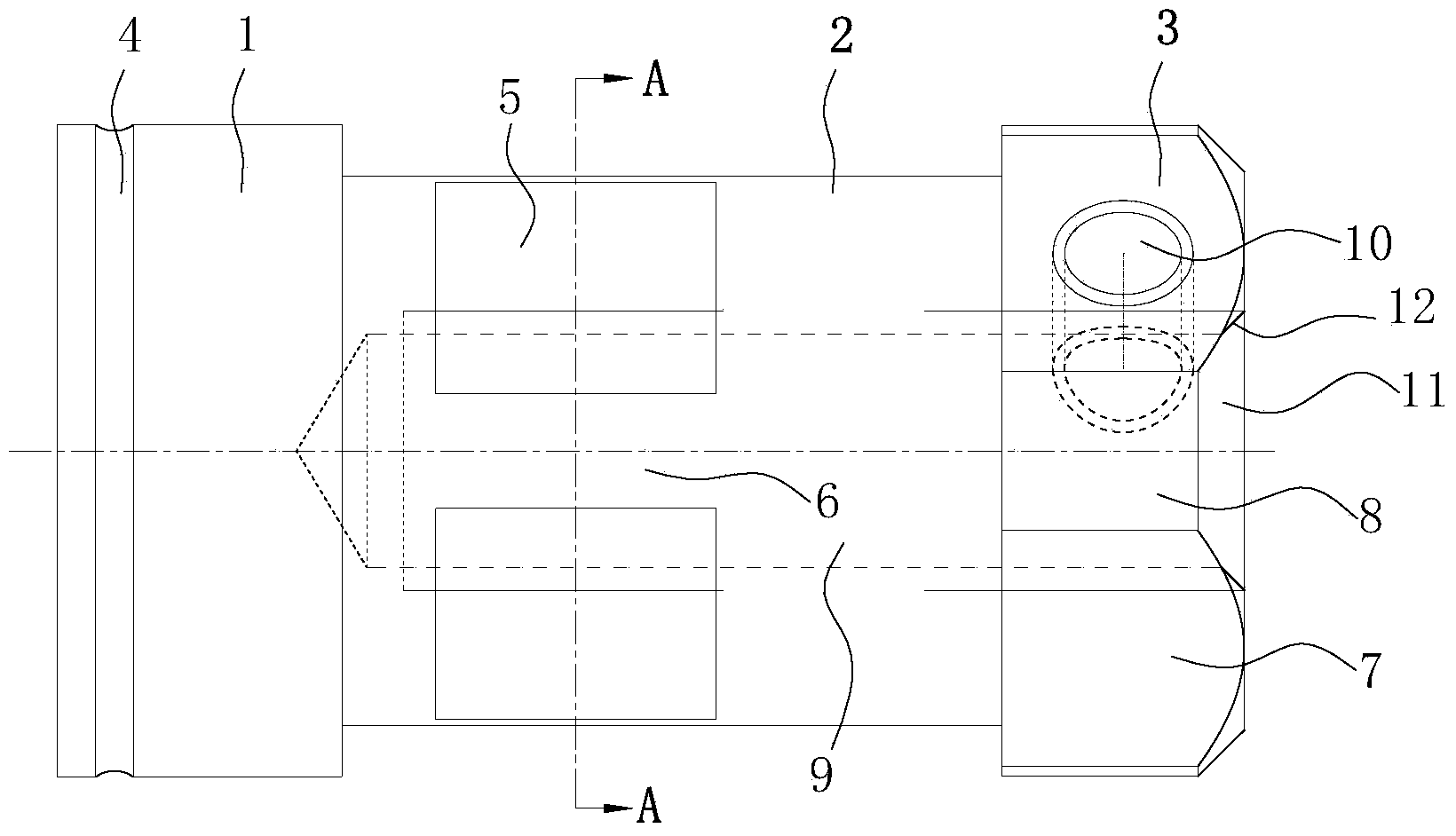

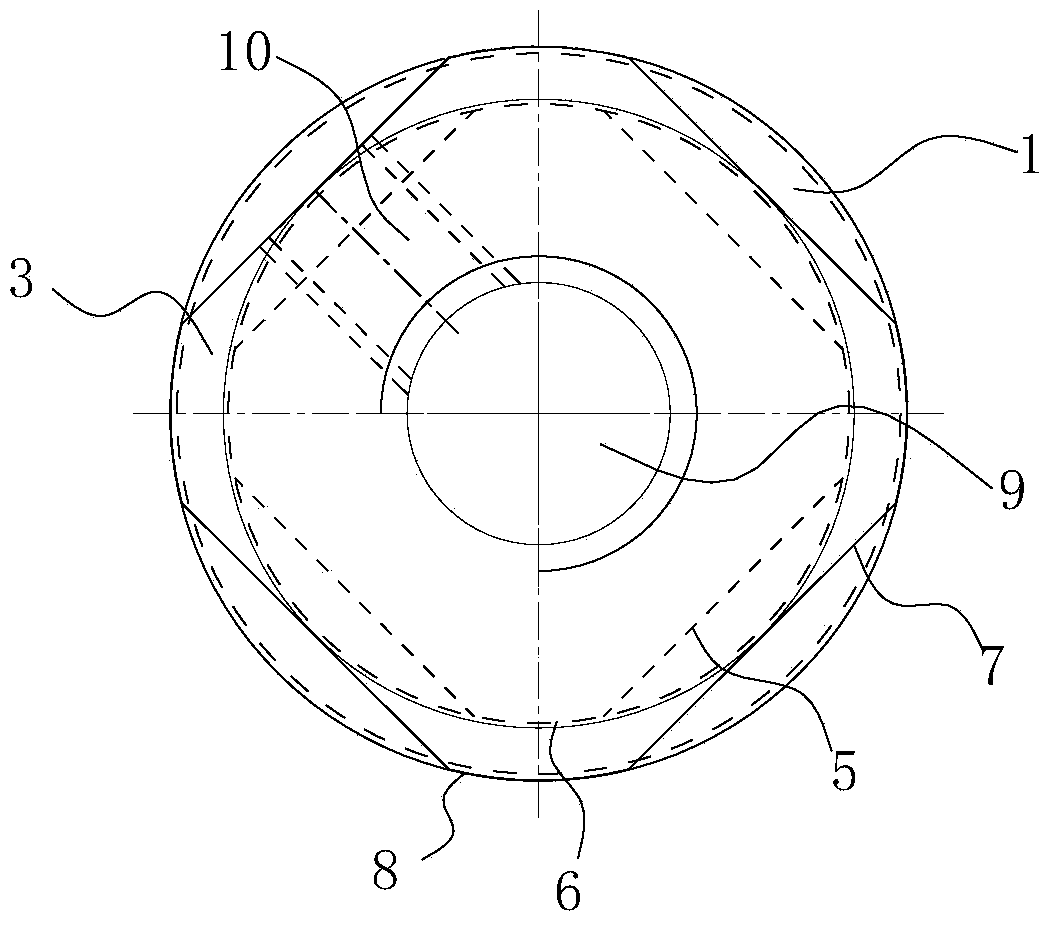

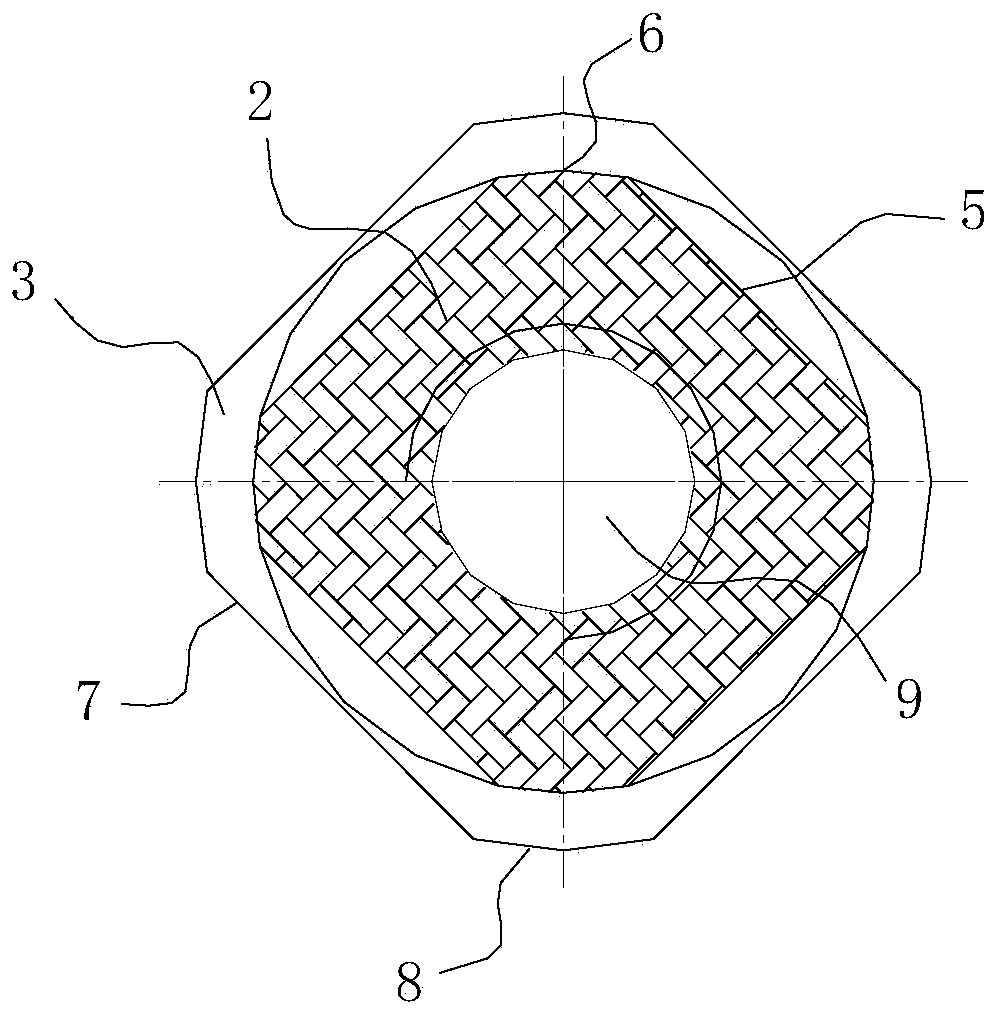

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0042] Such as Figures 1 to 3 In the shown embodiment, the tungsten steel push rod of the present invention includes a cylindrical push rod body, and the push rod body includes a first part 1 of the push rod coaxially arranged from left to right, a second part 2 of the push rod and The third part 3 of the push rod, the outer diameter of the first part 1 of the push rod is equal to the outer diameter of the third part 3 of the push rod, and the outer diameter of the first part 1 of the push rod is larger than the outer diameter of the second part 2 of the push rod.

[0043] A groove 4 is annularly arranged around the axis of the push rod body on the outside of the first part 1 of the push rod.

[0044] Four first planes 5 are evenly distributed around the periphery of the second part 2 of the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com