Continuous flow forming molding method different-radii metal plate manufactured flow forming belt pulley

A spinning forming, pulley technology, applied in the direction of belt/chain/gear, forming tools, components with teeth, etc., to achieve the effect of high product quality, accurate dimensional accuracy, and avoiding failure to form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A continuous spinning forming method for sheet metal spinning pulleys with unequal diameters, wherein there are N=4 small-diameter V-shaped grooves and M=4 large-diameter V-shaped grooves on the outer ring of the unequal-diameter sheet metal spinning pulley groove, the forming method of the unequal-diameter sheet metal spinning pulley includes blanking, deep drawing, shape correction, punching, edge trimming, material distribution and spinning forming processes, the blanking, deep drawing, shape correction, punching Hole, edge trimming, and material distribution process are the same as the above-mentioned steps of the forming method of the conventional unequal-diameter sheet metal spinning pulley with V-shaped grooves on the outer rim, and will not be repeated here.

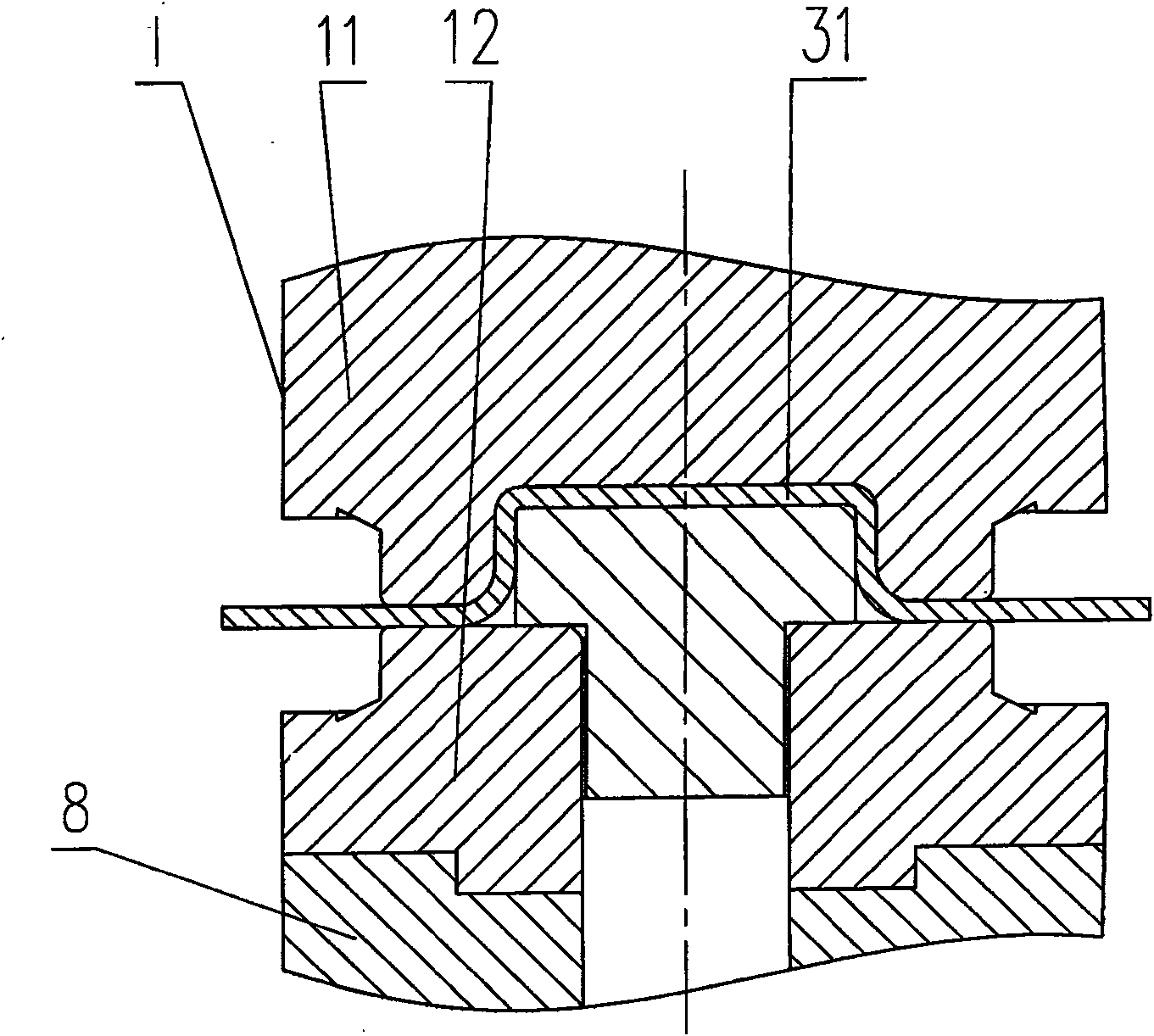

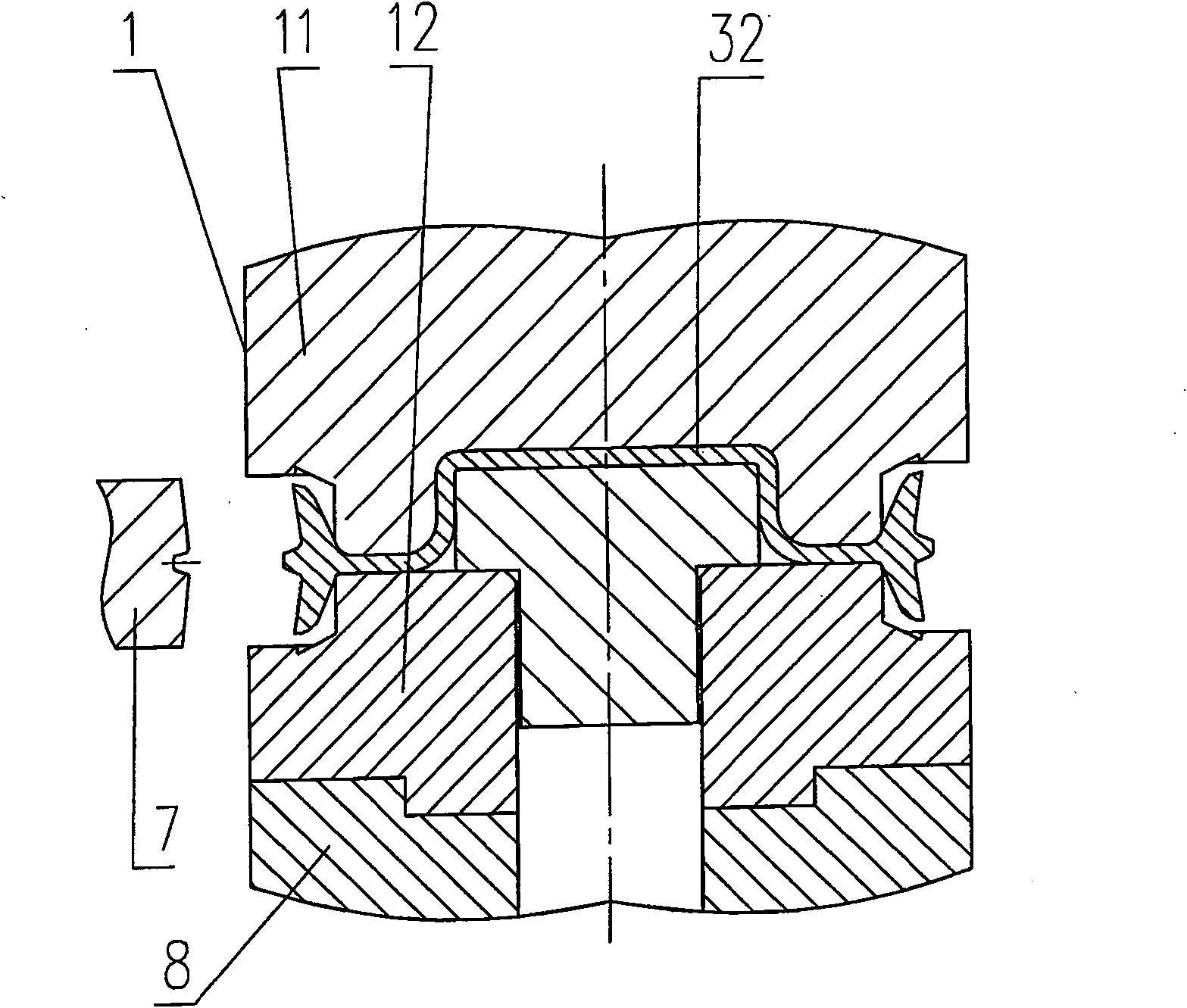

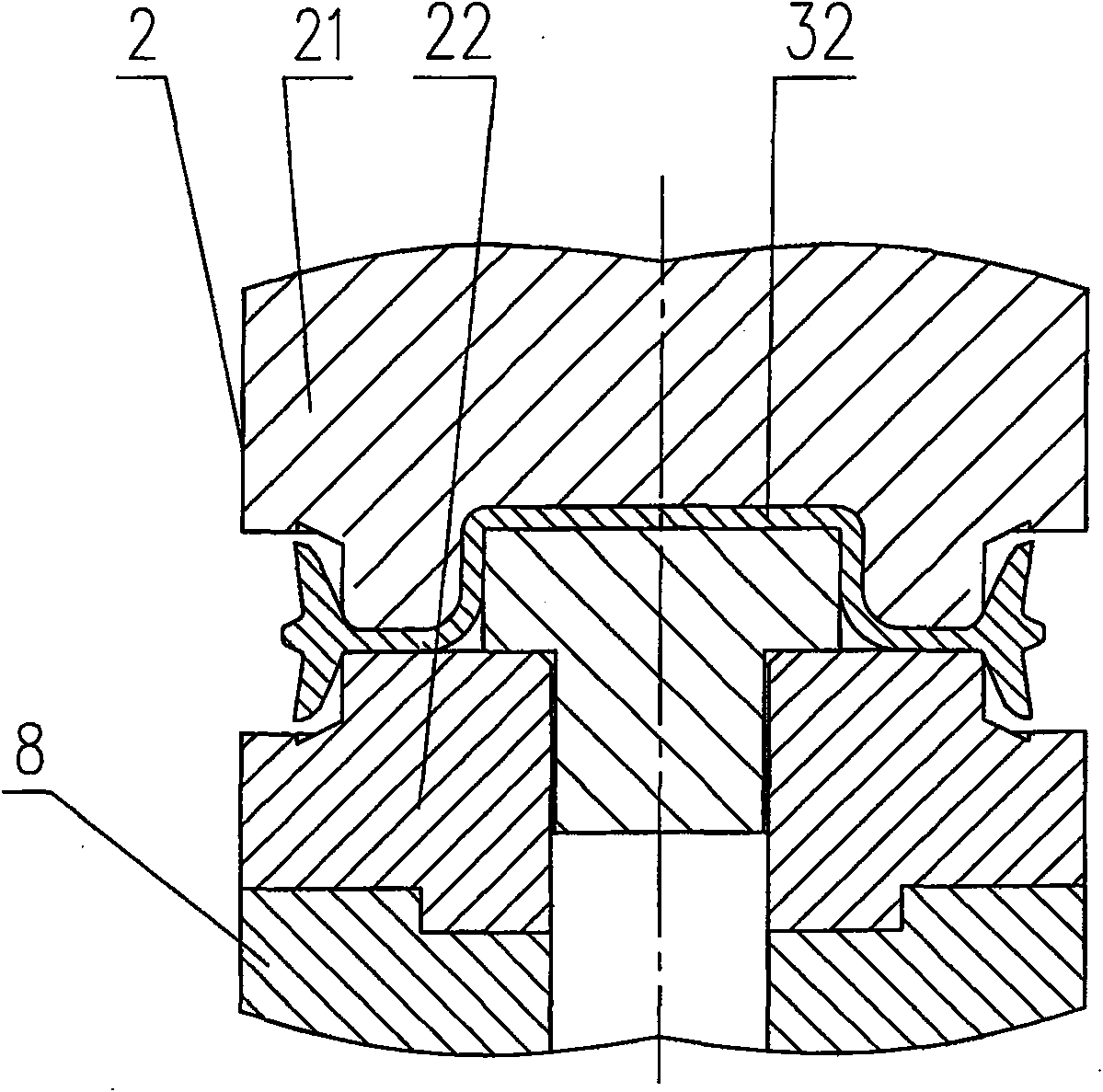

[0045] The described spinning forming process is a continuous spinning forming process. First, use 5 pairs of preforming wheels with small-diameter U-shaped grooves and large-diameter U-shaped grooves at th...

Embodiment 2

[0060] The invention relates to a continuous spinning forming method of spinning belt pulleys made of sheet metal with unequal diameters whose material dividing process is spinning.

[0061] This embodiment is a further improvement on the implementation of Example 1. It connects the common material distribution process and the spinning forming process of the present invention into a continuous spinning forming process, which includes material distribution spinning and spinning forming two steps, the said sub-spinning is to send the yu-shaped pulley blank into the sub-spinning mold for sub-processing, and make the yu-shaped pulley blank with a 'Y' shape on the edge. The spinning forming process is to use a pre-formed wheel with a small-diameter U-shaped groove and a large-diameter U-shaped groove to pre-spin the 'Y'-shaped Yu-shaped pulley blank, and then use a small-diameter V-shaped pulley blank. The forming wheel of the V-shaped groove and the large-diameter V-shaped groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com