Large-scale truss type stake leg segmentation data detection method

A detection method and technology of segmented data, applied in measurement devices, water conservancy projects, artificial islands, etc., can solve the problem of high strength requirements, achieve high detection accuracy, ensure quality, and reduce the possibility of platform damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The segmental data detection method of the large-scale truss-type pile legs of the present invention includes the detection of the main dimensions of the pile legs, wherein:

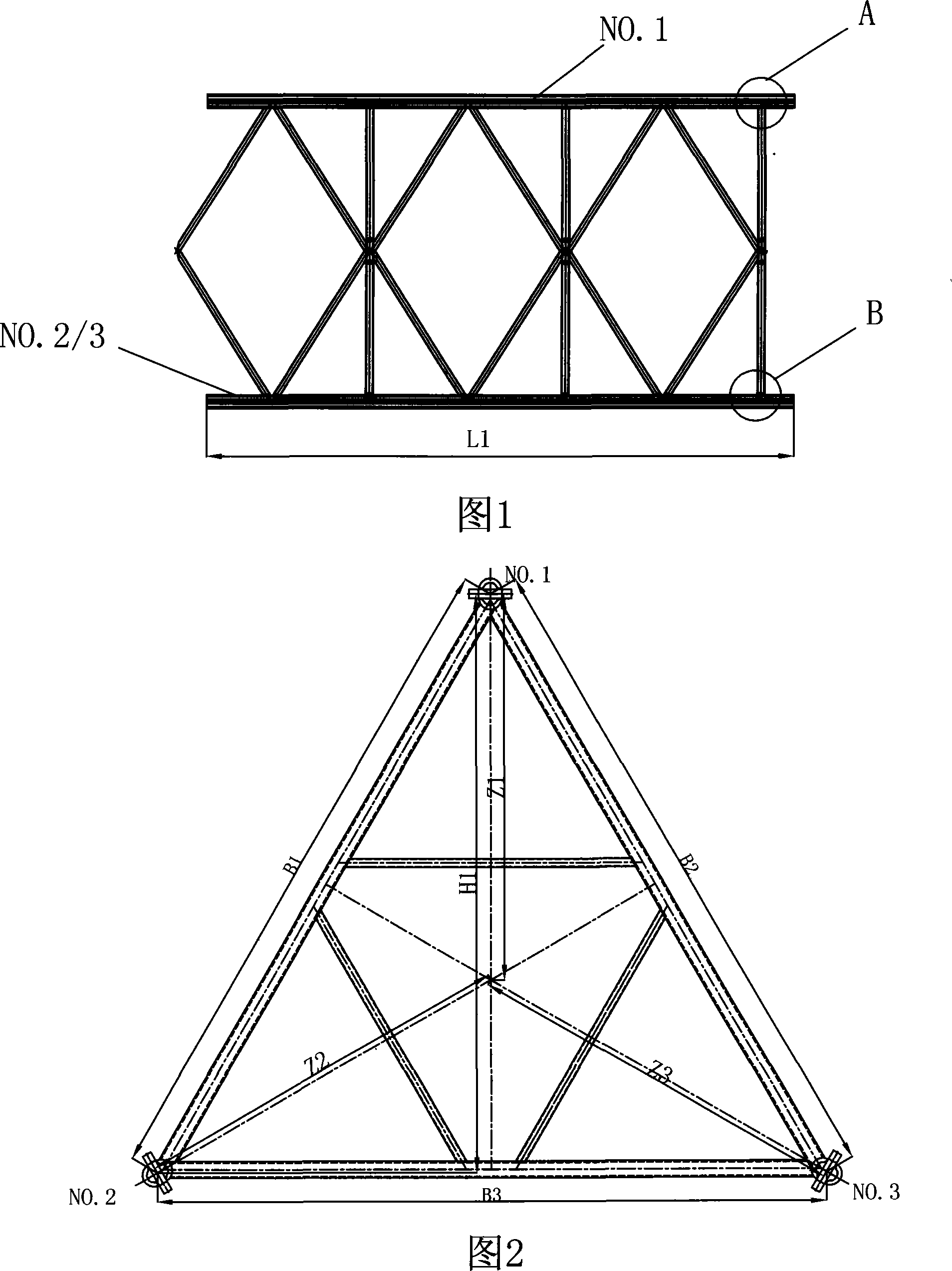

[0016] a. The length L1 of the leg segment is detected by the distance between the two ends of the leg segment-main side tube (as shown in Figure 1);

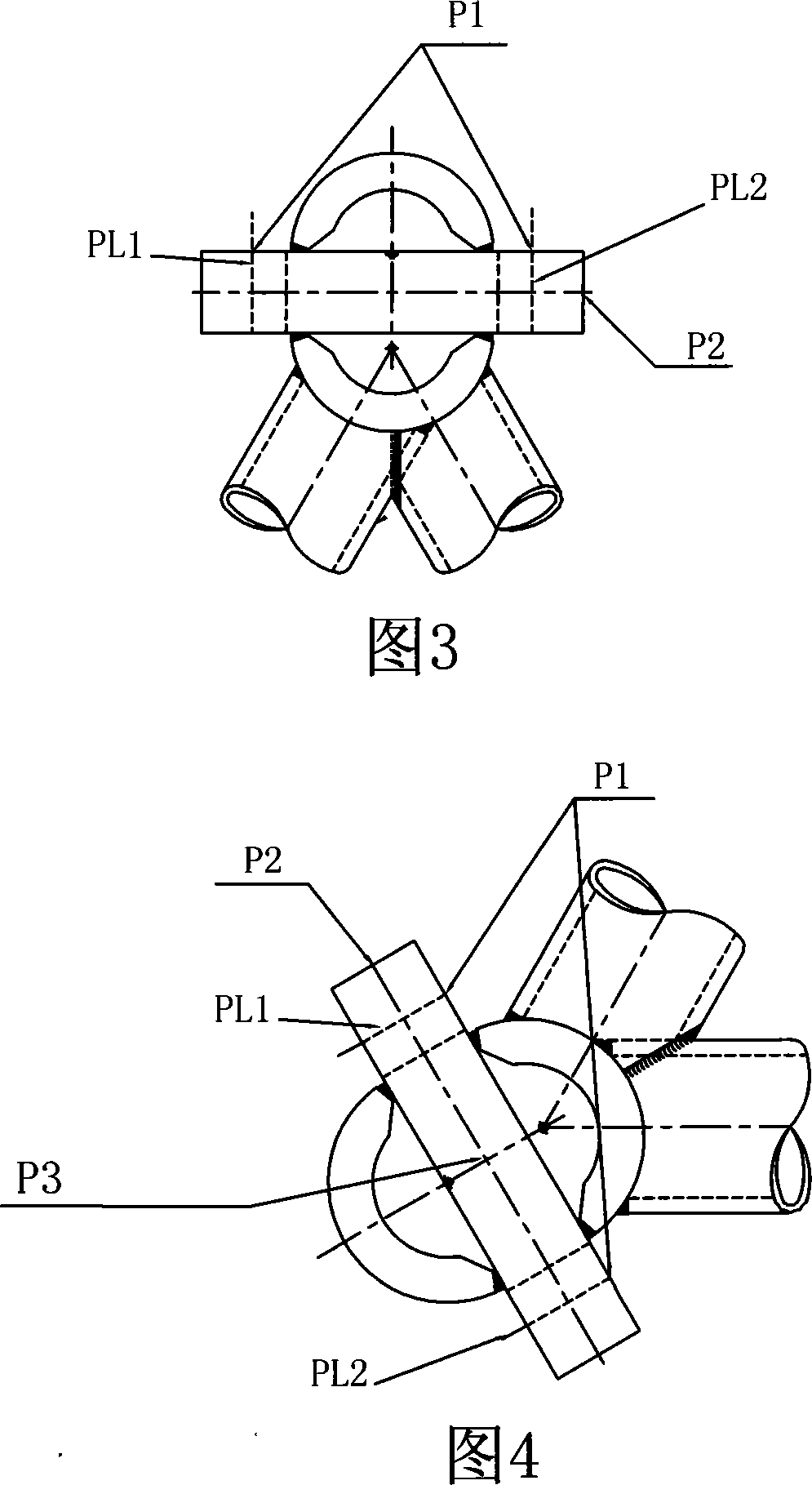

[0017] b. The leg segment height H1 is detected through the vertical distance from the main side tube to the opposite surface of the leg segment (that is, the distance from the center point of the end of the main side tube to the opposite surface of the leg segment) (as shown in Figure 2);

[0018] c On the cross section, the distances Z1, Z2 and Z3 from the rack plate to the segmented center of the leg are detected through the distance from the center point of the main side tube end to the center of the segmented equilateral triangle of the opposite leg (as shown in Figure 2);

[0019] d Detect the rack plate spacing B1, B2, B3 (as shown in Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com