Safety protective device used for numerical-control grinding machine

A safety protection device, the technology of CNC grinding machine, applied in the direction of grinding/polishing safety device, grinding drive device, grinding machine parts, etc. problem, to avoid the horizontal flying of workpiece debris and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

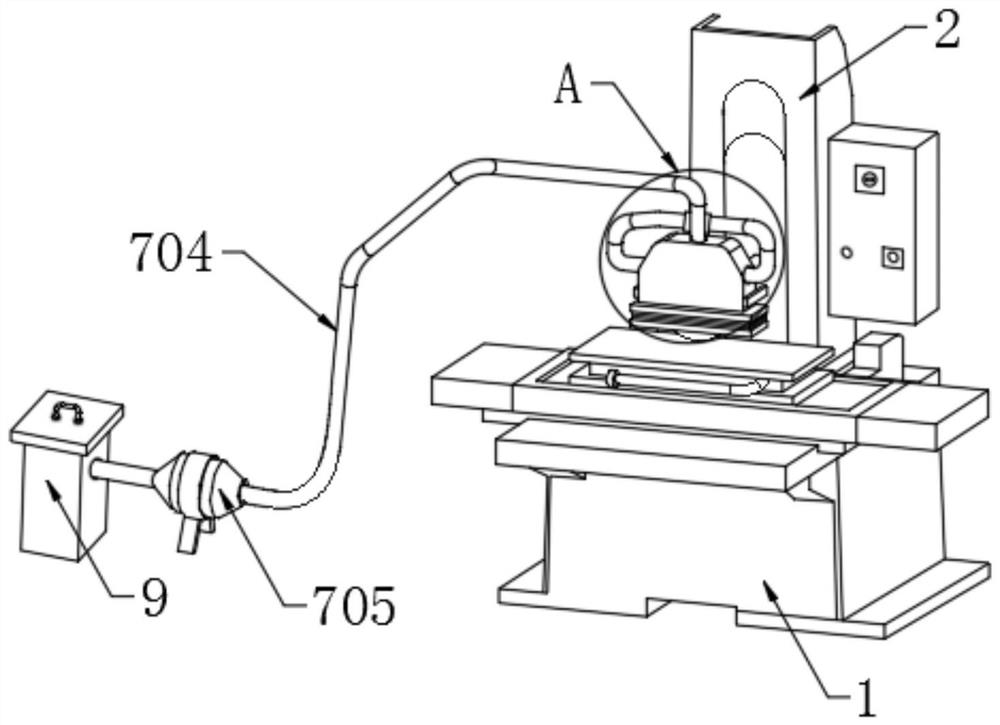

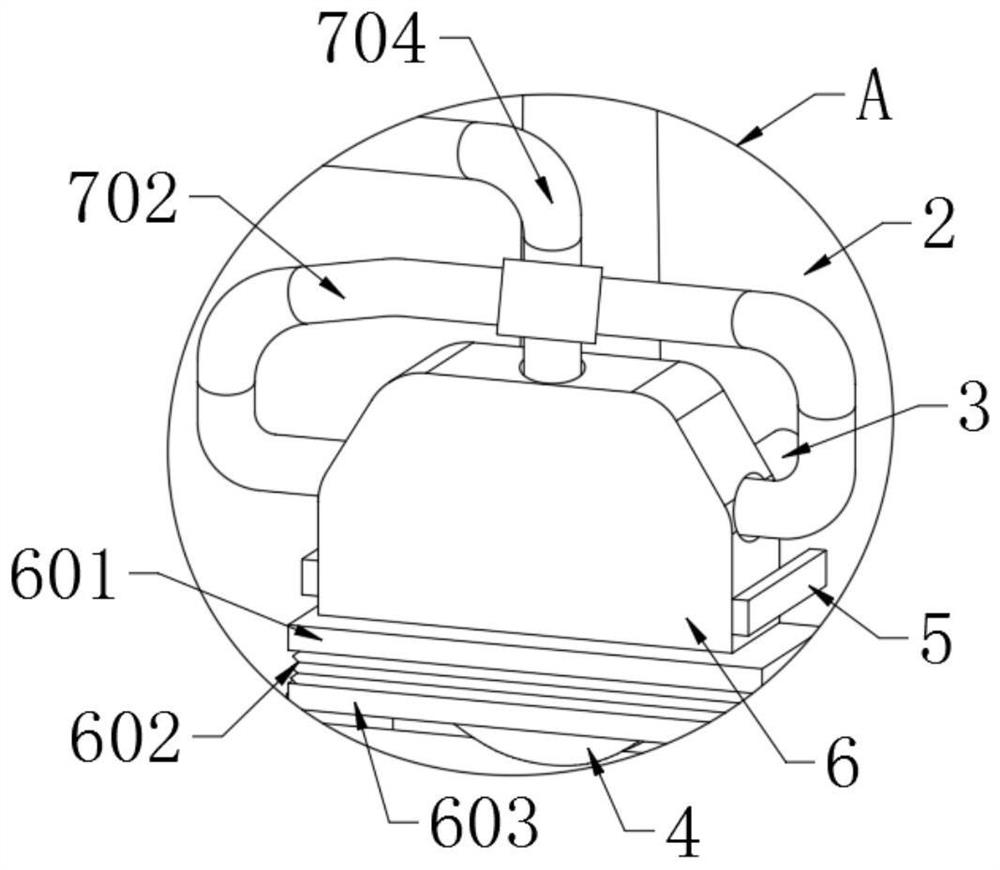

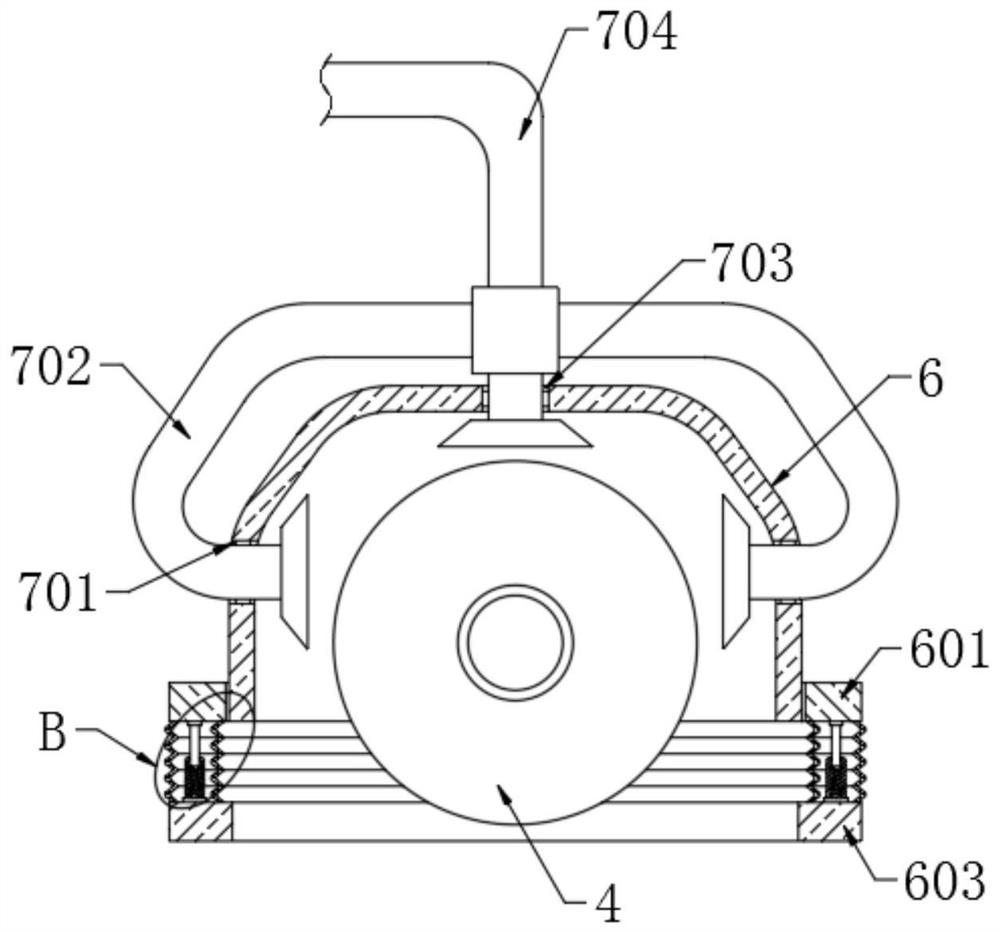

[0026] refer to Figure 1-6 In this embodiment, a safety protection device for a CNC grinding machine is proposed, including a stand 1, a support frame 2 is fixedly installed on the top of the stand 1, a motor 3 is fixedly installed on one side of the support frame 2, and a motor 3 is fixedly installed on the top of the stand 1. A grinding wheel 4 is fixedly installed on the output shaft, two connecting rods 5 are fixedly installed on the side of the support frame 2 close to the grinding wheel 4, and the same protective cover 6 is fixedly installed on the side where the two connecting rods 5 are close to each other. 6. A through hole is opened on the inner wall of one side close to the support frame 2. The output shaft of the motor 3 passes through the through hole and is connected to the inner wall of the through hole in rotation. Both are provided with a first installation hole 701, and a first conduit 702 is fixedly installed in the two first installation holes 701, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com