Processing method of aspherical optical element of optical glass and silicon monocrystal

A technology of optical glass and optical components, which is applied in the direction of optical surface grinders, metal processing equipment, manufacturing tools, etc., can solve the problems of long component cycle, high cost, difficult to guarantee accuracy, etc., and achieve the goal of improving production efficiency, cost and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

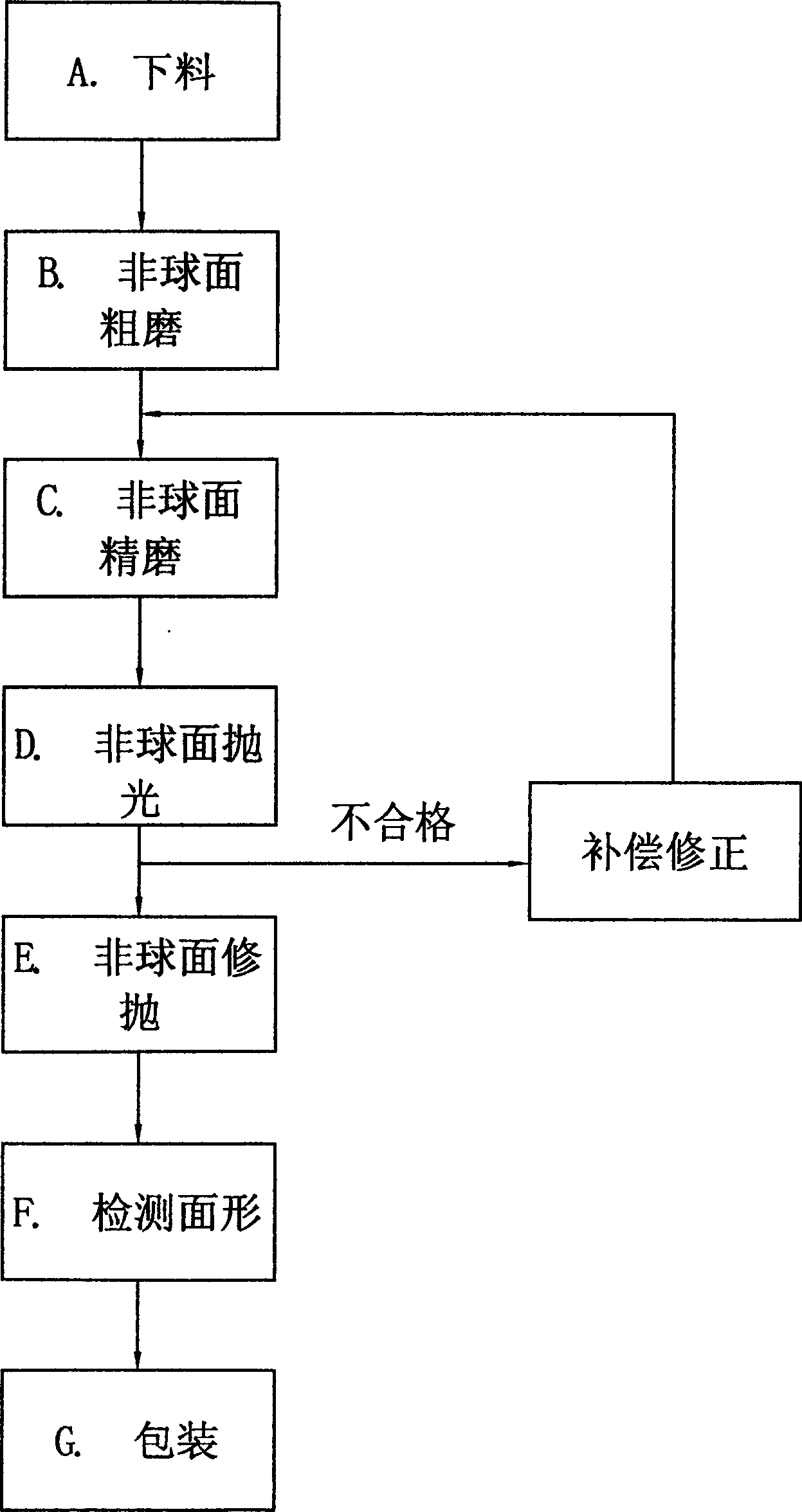

Method used

Image

Examples

Embodiment 1

[0027] Example 1, processing aspherical optical elements twice, such as Figure 5 As shown, surface A is aspherical, material: optical glass material or silicon single crystal material, Φ=17 mm, aspherical vertex radius R 0 = 10.085 mm, δ = 5 mm, 2nd degree aspheric equation: Y = C X 2 / 1 + 1 - ( 1 + K ) C 2 X 2 , Among them, Y represents the vertical distance from any point on the aspheric surface to the vertex of the aspheric surface, which is called arc height, X is the data of any point on the effective radius of the aspheric surface Φ / 2=8.5 mm, K is the surface shape coefficient, K=-1.490242, C= 1 / R 0 = 0.0991571641,

[0028] A. Blanking, according to...

Embodiment 2

[0036] Example 2: Process 10 aspherical optical elements, such as Image 6 As shown, A is an aspheric surface, material: optical glass or silicon single crystal, Φ=60 mm, R=92.04 mm, δ 1 = 12.33 mm, δ 2 = 10.76 mm, aspheric effective radius Φ / 2 = 30 mm, aspheric vertex radius R 0 = 215.985 mm. Aspheric equation: Y = C X 2 / 1 + 1 - ( 1 + K ) C 2 X 2 + a 2 X 2 + a 3 X 3 + a 4 X 4 + . . ...

Embodiment 3

[0045] Embodiment 3, processing 15 aspherical optical elements, such as Figure 7 As shown, A is an aspheric surface, material: optical glass or silicon single crystal material, Φ=82 mm, δ 1 = 4.37 mm, δ 2 = 3.98 mm, R = 64.86 mm, R 0 = 30.70475 mm, 15th degree aspheric equation:

[0046] Y = C X 2 / 1 + [ 1 - ( 1 + K ) C 2 X 2 + a 2 X 2 + a 3 X 3 + a 4 X 4 + . . . . . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com