Horizontal single-sided numerical control grinding spring machine

A spring machine, single-sided technology, used in grinding frames, parts of grinding machine tools, machine tools suitable for grinding workpiece planes, etc., can solve uneven product quality, low work efficiency, high labor intensity, etc. problems, to achieve the effect of stable and unified quality of finished products, improving quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

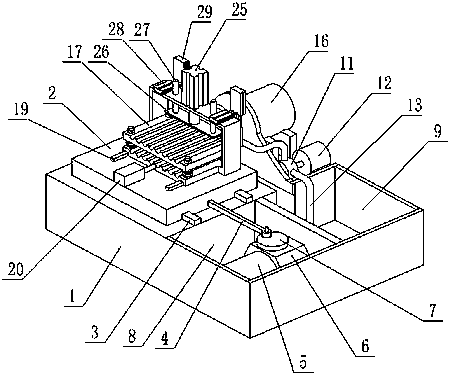

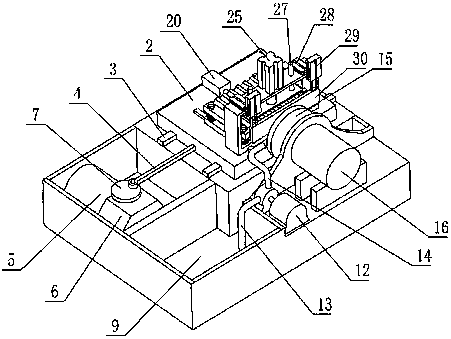

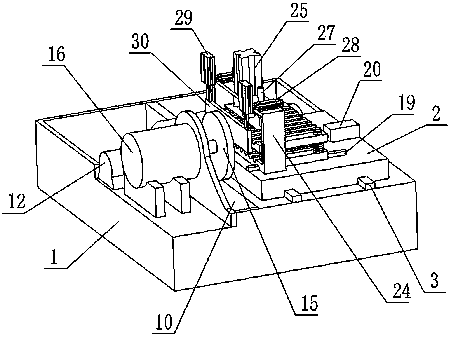

[0015] For specific examples, see Figure 1-5 , a horizontal single-sided numerical control spring grinding machine, including an operating table 1 and a slide plate 2, the operating table 1 is provided with a circulating water tank 9, a water return tank 10 and a motor placement box 8, and the circulating water tank 9 and the water return tank 10 Connected to each other, a slide guide rail 3 is fixed on the console 1, the slide plate 2 is arranged on the slide guide rail 3, a slide drive motor 5 is placed in the motor placement box 8, and the slide drive motor 5 can pass through the gearbox 6. The turntable 7 and the pull rod 4 drive the slide plate 2 to reciprocate on the slide guide rail 3. A water pump motor 12 and a grinding wheel drive motor 16 are fixed on the operating table 1. A grinding wheel 15 is provided directly above the return tank 10. The emery wheel driving motor 16 can drive the emery wheel 15 to rotate, and the corresponding water pump motor 12 on the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com