Ceramic bonding agent cubic boron nitride grinding wheel applied for camshaft grinding processing

A technology of cubic boron nitride and ceramic bond, which is applied in bonded grinding wheels, metal processing equipment, abrasives, etc., can solve the problem of low durability and service life of ordinary abrasive grinding wheels, increased auxiliary time and labor intensity, and increased grinding fluid Filter cleaning volume and other issues to achieve the effect of good self-sharpening, long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

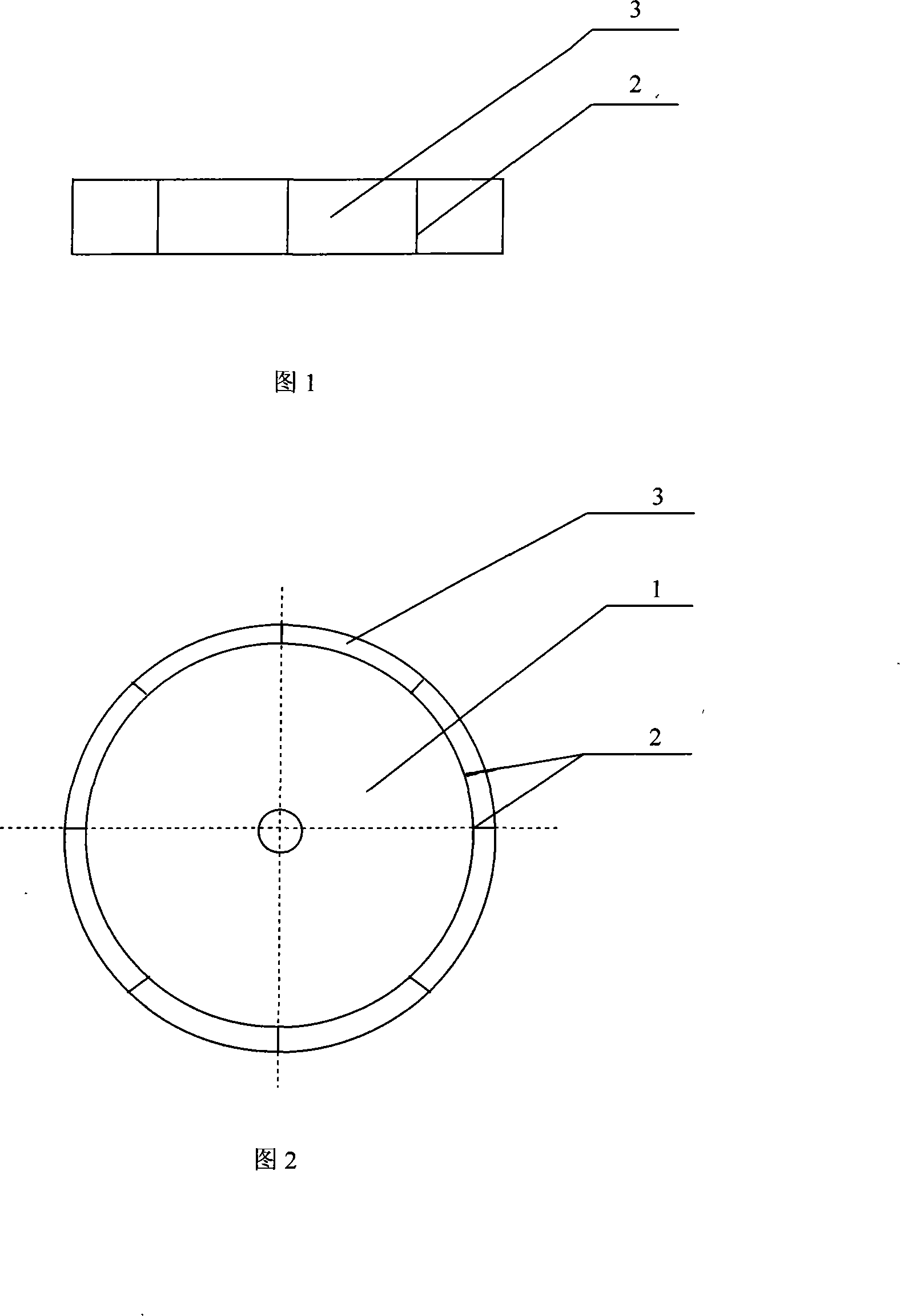

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the inventive concepts and embodiments of the present invention.

[0016] Cubic boron nitride is the second-hardest material known in the world after diamond, but the chemical stability of diamond and iron group elements is poor, so it cannot be used for grinding most metals and alloys, so cubic boron nitride is suitable for grinding Hardest grinding material for machining most metals and alloys. Cubic boron nitride abrasives not only have high hardness, but also have good thermal stability and chemical inertness. Compared with ordinary abrasives, cubic boron nitride grinding tools can not only solve the processing problems of hard, tough and difficult-to-grind materials, but also meet the needs of new materials. Grinding processing, and the grinding tool has sharp grinding, good wear resistance, small unit wear, good surface quality of the processed workpiece, and high production efficiency. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com