Measuring, monitoring and machining integrated device of numerical control deep hole inner circle grinding machine and control system

An internal grinding machine, monitoring and processing technology, applied in the direction of grinding drive device, grinding automatic control device, workpiece feed movement control, etc., can solve the problem of poor consistency of processing accuracy and surface quality, poor accuracy and reliability, and time-consuming Problems such as laboriousness, to achieve the effect of improving processing efficiency and controllability of processing engineering, ensuring poor accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings.

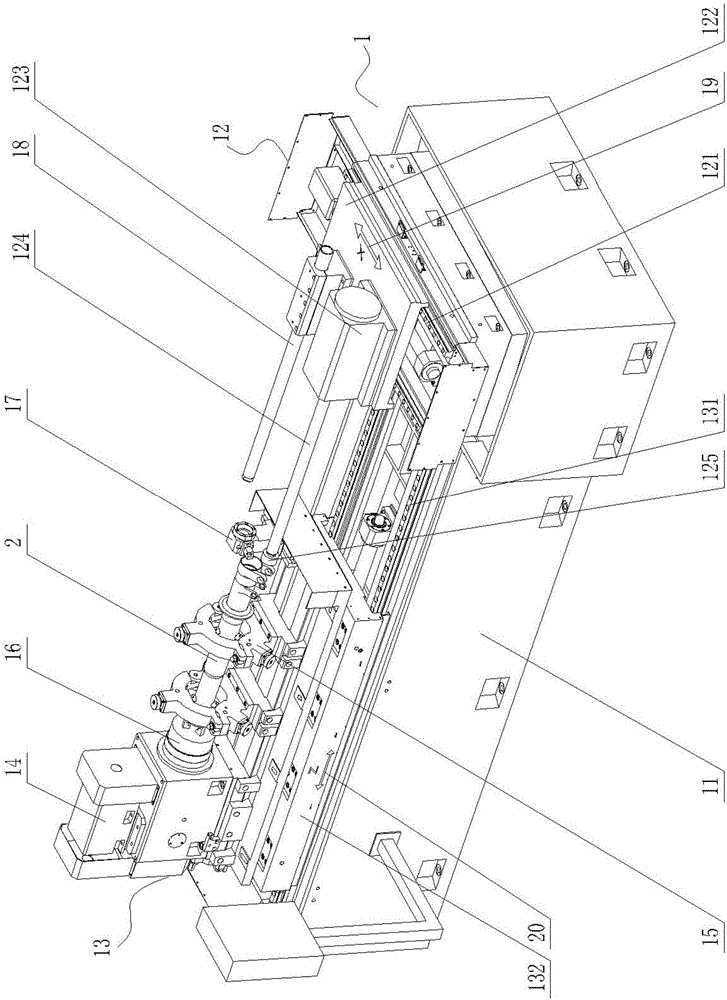

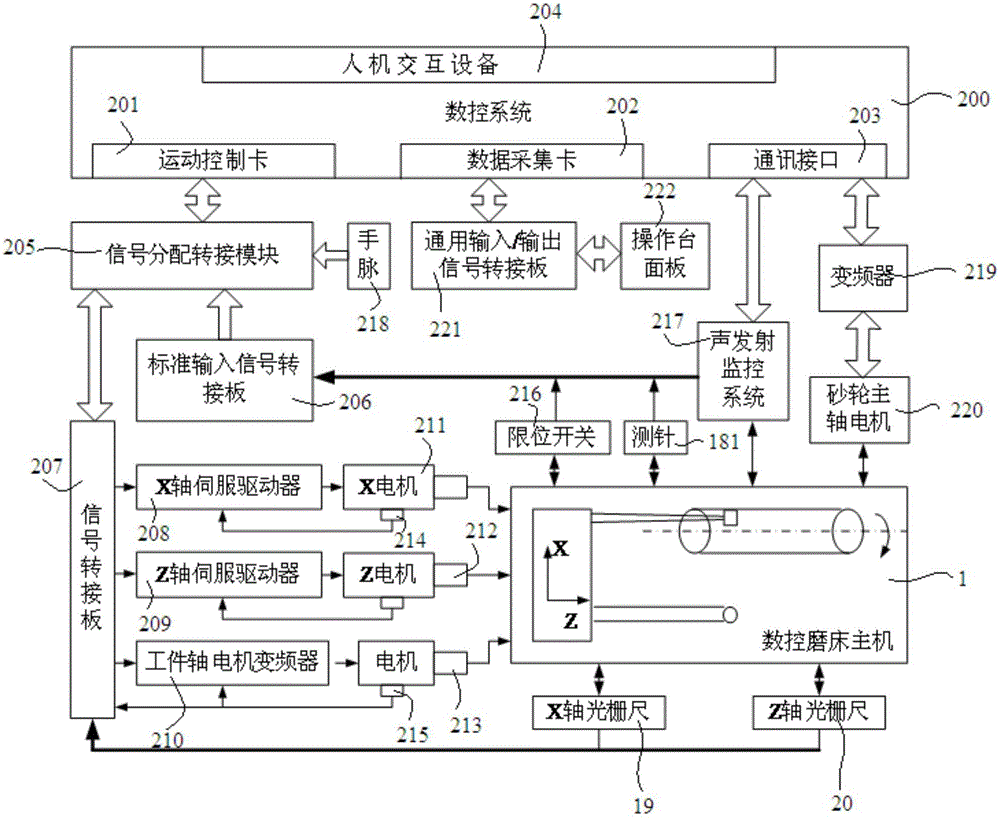

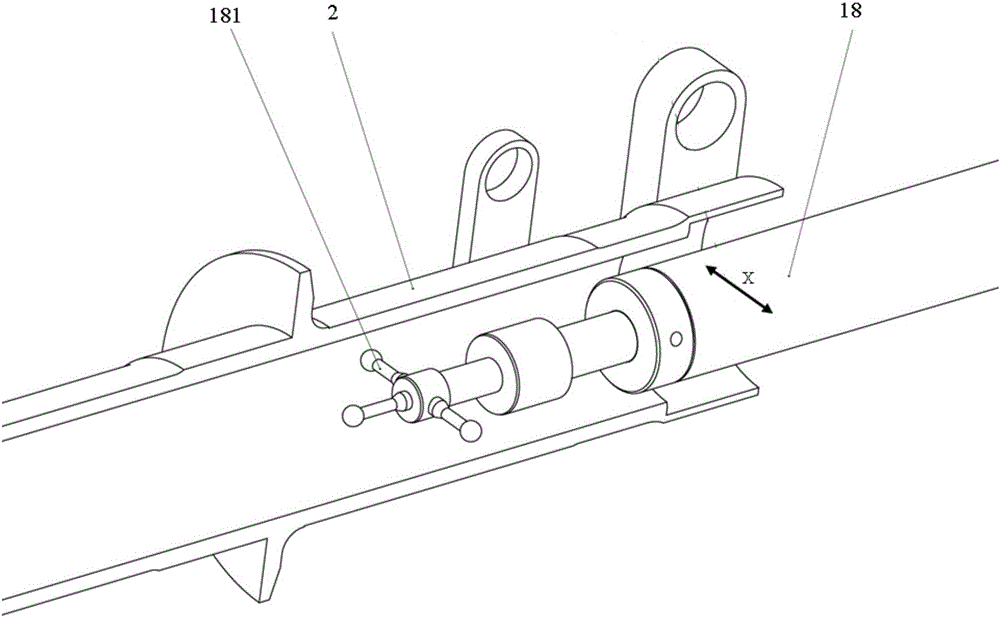

[0025] Such as figure 1 As shown: the integrated device for measurement, monitoring and processing of the CNC deep hole internal grinding machine of the present invention, including the CNC grinding machine host 1 and the in-situ measuring device for the size and shape of the deep hole, and the bed 11 of the CNC grinding machine host 1 adopts a "T" shape layout Horizontal structure, X-axis feed system 12 and Z-axis feed system 13 are arranged on the upper surface of the bed 11; the Z-axis feed system 13 includes Z-axis guide rail 131, and a worktable slidingly arranged on Z-axis guide rail 131 132, and the Z-axis driving device that drives the workbench 132 to slide along the Z-axis guide rail 131; on the workbench 132, a headstock 14 and a center frame 15 and an emery wheel dresser 17 for supporting the workpiece 2 are installed, the headstock 14 is provided with a chuck 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com